A method of drilling holes using a drilling device for automobile pipelines

A technology of automobile pipelines and drilling devices, which is applied in the direction of drilling/drilling equipment, boring/drilling, boring machine/drilling machine parts, etc., which can solve the problems of loading interference, abnormal work, and affecting the performance of the whole vehicle And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

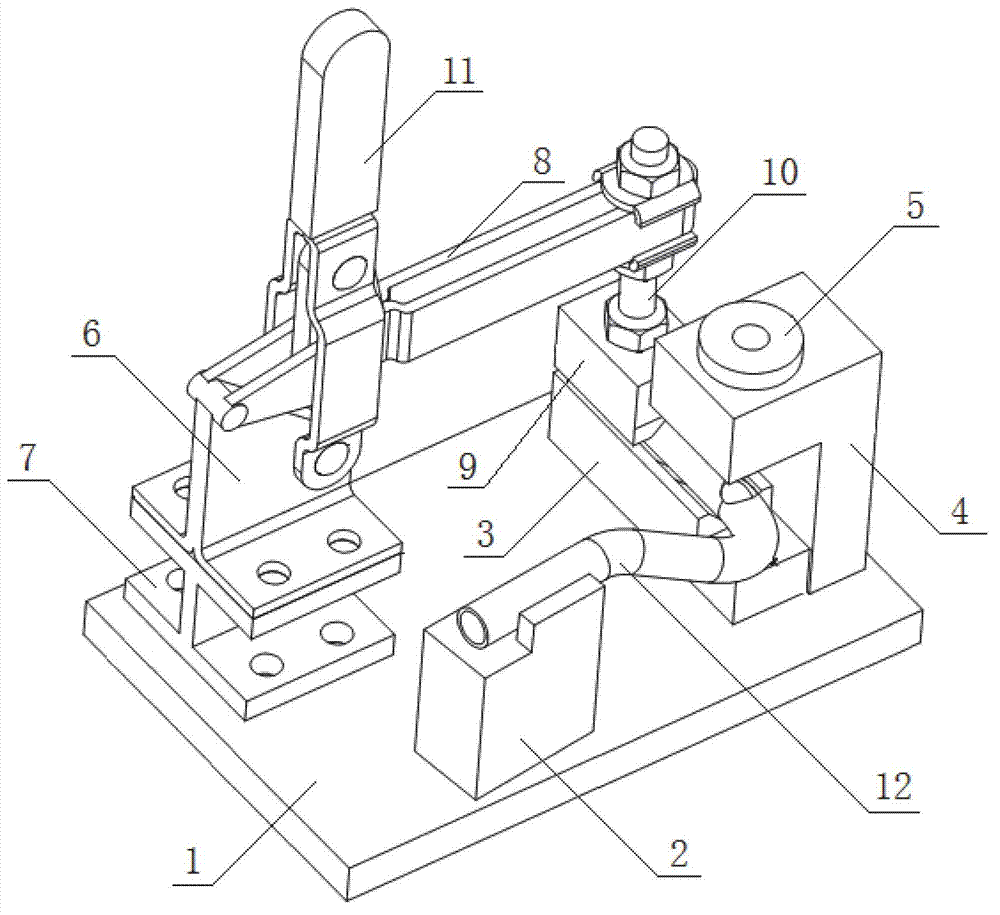

[0016] Depend on figure 1 As can be seen from the shown structure, this kind of drilling device for automobile pipelines includes a base plate 1 and a positioning device and a clamping device for positioning and clamping the automobile pipeline 12 to be drilled on the base plate 1; The road 12 is divided into an area to be drilled and a non-drilled area, and the positioning device includes a first positioning column 2 supporting the non-drilling area, a second positioning column 3 supporting the area to be drilled, and pressing the area to be drilled. Tight third positioning column 4, and the second positioning column 3 is provided with a V-shaped groove for installing the automobile pipeline 12 to be drilled, and the third positioning column 4 is provided with a drill sleeve 5 that guides the drill bit; the clamping device It includes a clamping device 6 fixed on the base plate 1 through a clamping device base 7, a clamping arm 8 that rotates around the clamping device 6 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com