Method for forming fiber pipe piece

A molding method and technology for pipe fittings, which are applied in the direction of tubular articles, other household appliances, household appliances, etc., can solve the problems of uneven pipe wall, inconvenient production and processing, cracks, etc., so as to improve the uniformity of pipe wall, reduce production cost, The effect of preventing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

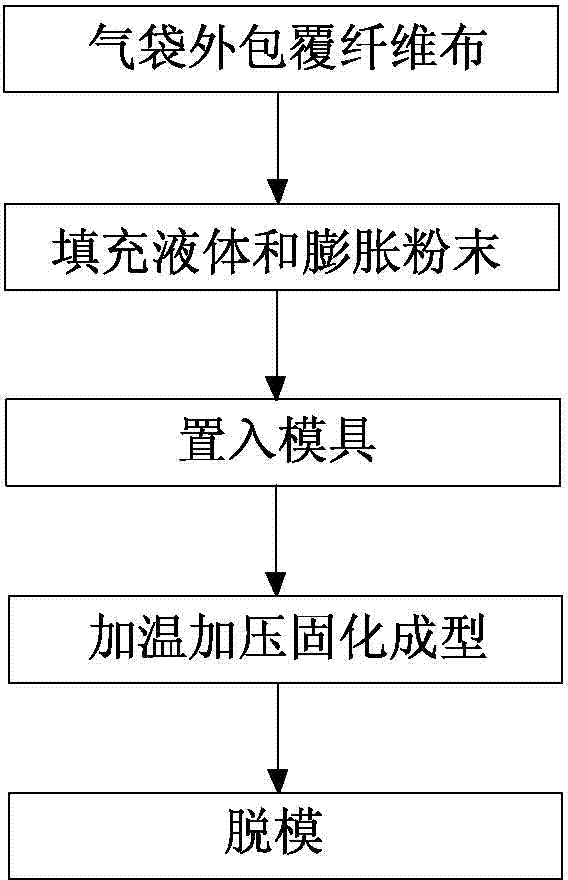

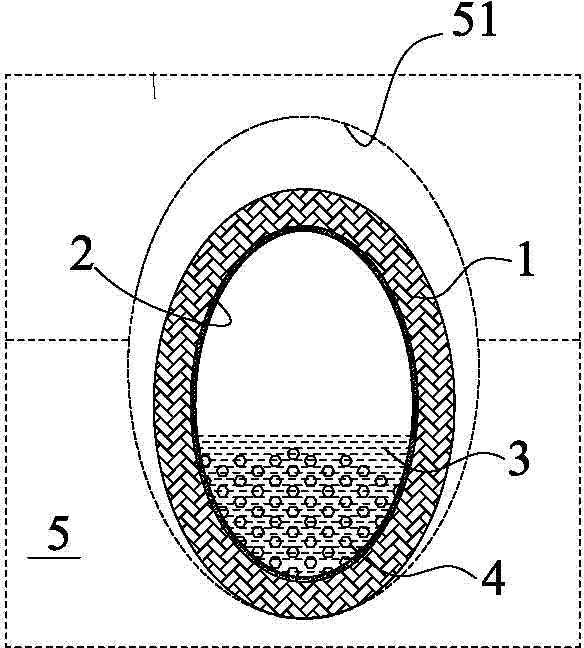

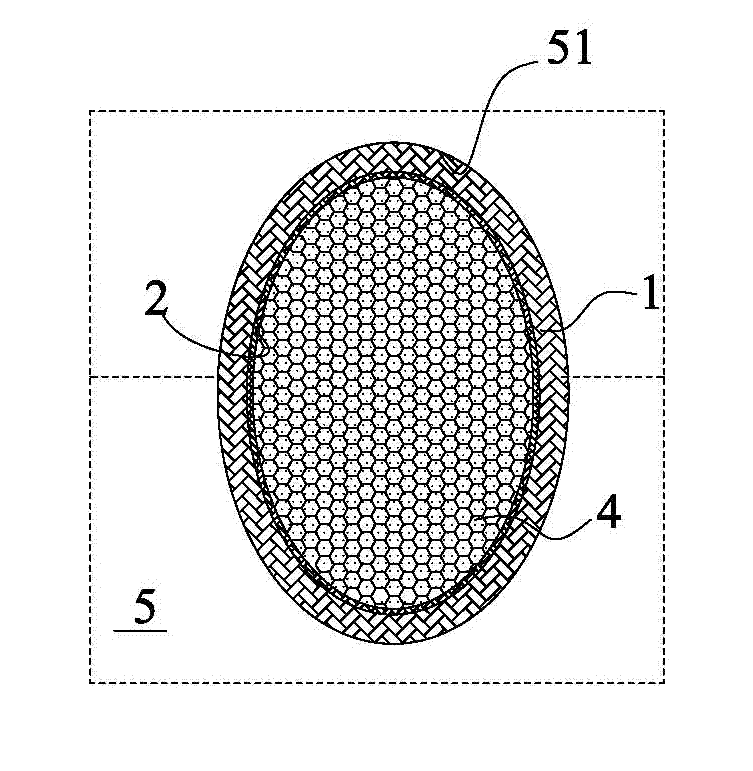

[0021] see Figure 1 to Figure 4 As shown, a molding method of fiber pipe fittings, the steps are as follows: First, the air bag 2 is covered with fiber cloth 1 and processed: the core mold can be used as the winding center to roll the fiber cloth, and the core mold is pulled out and inserted into the air bag. The air bag is covered with fiber cloth to form a tube; or the air bag and fiber cloth can be wound together, or the air bag is formed first, then the core mold is molded and then the fiber cloth is wound, so the air bag is outsourced. Covering the fiber cloth and promoting the fiber cloth to be shaped in the mold through expansion is a common technique in the art, which is not limited here. Second, the air bag 2 is filled with liquid 3 and expansion powder 4: two kinds of liquid 3 and expansion powder 4 are filled in the air bag 2 at di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com