Mobile phone shell and machining method thereof

A processing method and mobile phone shell technology, which is applied to chemical instruments and methods, telephone structures, layered products, etc., can solve the problems of high processing costs, achieve the effects of reducing processing volume, reducing costs, and ensuring appearance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

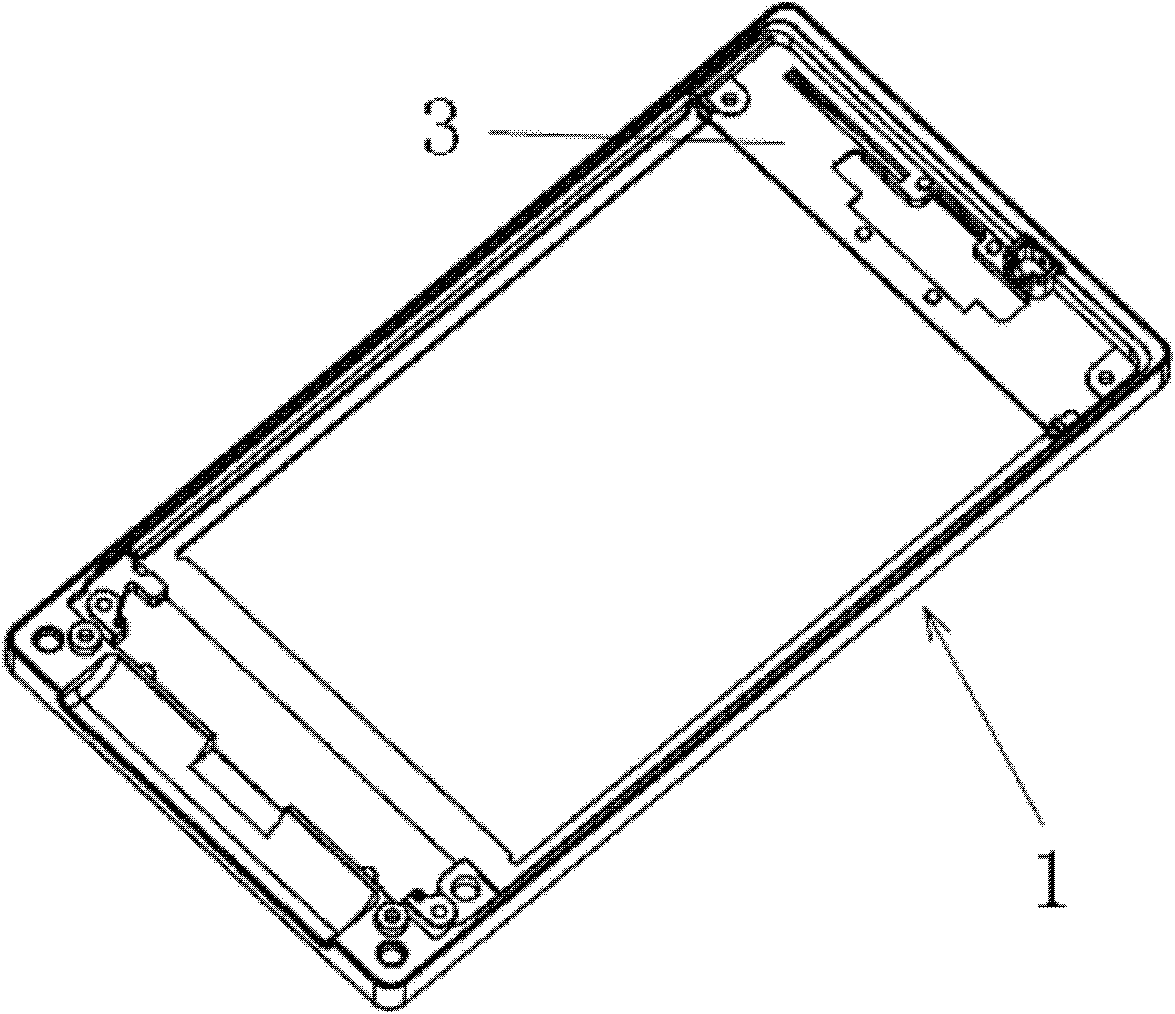

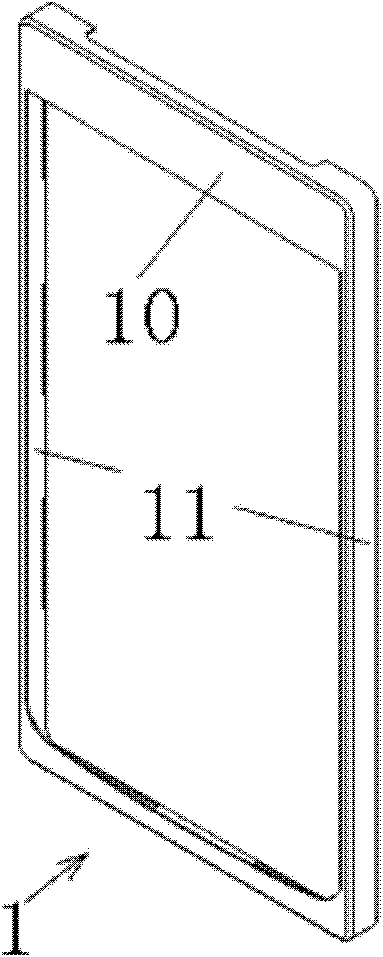

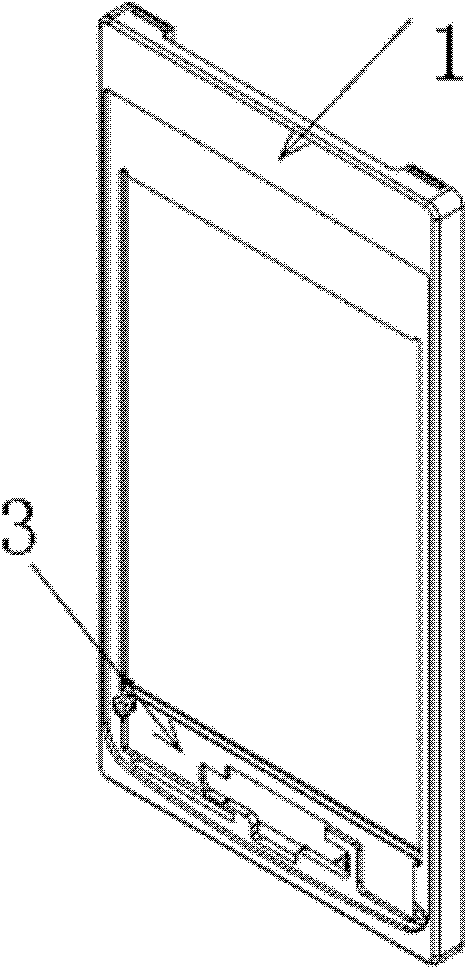

[0044] Such as Figure 1 to Figure 4 Shown is the first embodiment of the mobile phone case of the present invention. In this embodiment, the mobile phone case includes a shell 1. The shell 1 can be made of metal stamping, forging or injection molding. In this embodiment, metal The thin plate is punched to form the shell 1. The shell 1 can be stamped from metal plates such as stainless steel, aluminum, aluminum alloy, titanium or titanium alloy. The inner side of the shell 1 is welded with inserts. The mobile phone shell also includes metal die-casting on the shell 1. The inner shell 3 on the inner side, the insert is enclosed in the inner shell 3, that is, the insert is embedded in the inner shell 3, so as to ensure th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com