Novel radial drilling machine

A radial drilling machine and a new type of technology, applied in the field of machine tools, can solve the problems of easy wear of sliding surfaces and reduce the service life of machine tools, and achieve the effect of overcoming easy wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

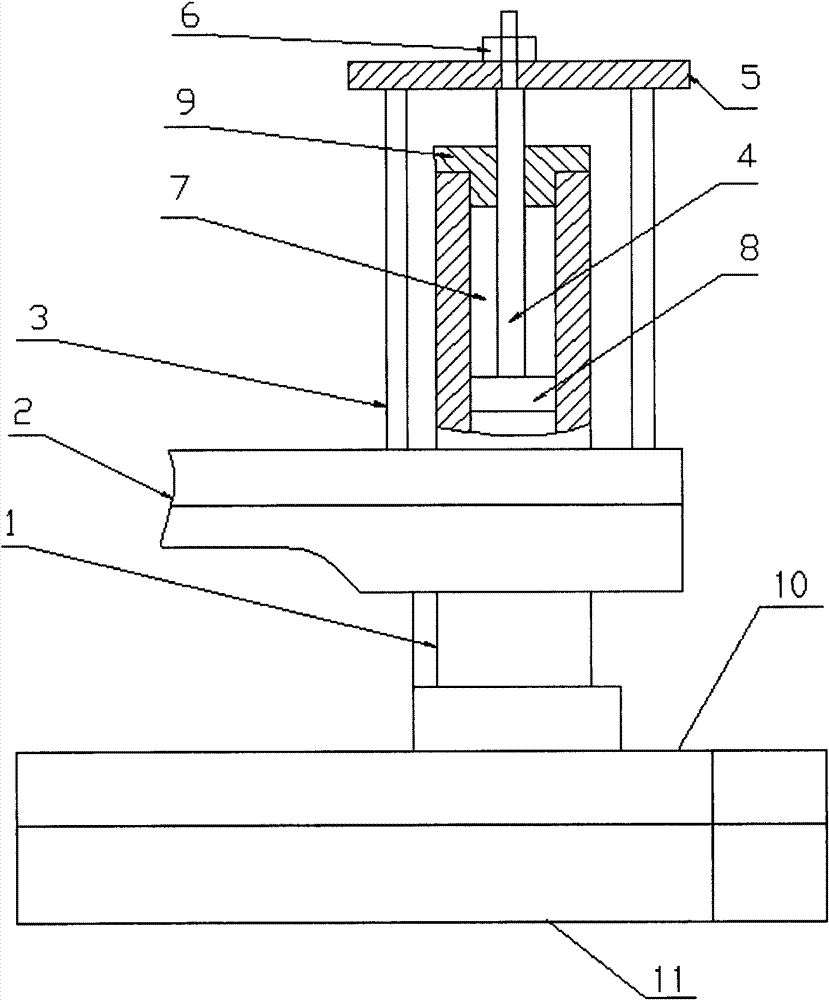

[0008] The radial drilling machine has a column 1, a cylinder 7 is manufactured in the middle of the column 1, a piston 8 is installed in the cylinder 7, a piston rod 4 is installed in the middle of the piston 8, and after the piston rod 4 passes through the middle hole of the cylinder head 9, use Bolts fix the cylinder head 9 on the upper mouth of the cylinder body 7, the beam 5 is fixed on the end of the piston rod 4 with a lock nut 6, one end of the tie rod 3 is fixed to the beam 5, and the other end is fixed to the double rocker arm 2, A workbench 10 is arranged below the column 1, and the workbench 10 is connected with the base 11 and the column 1 as a whole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com