A high-speed centrifugal threshing device for a grain combine harvester

A combine harvester and high-speed centrifugation technology, used in harvesters, threshing equipment, cutters, etc., can solve the problems of increased machine energy consumption, poor separation effect of the combine harvester, high breakage rate, and increased internal space. , The effect of stable operation and reduced loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

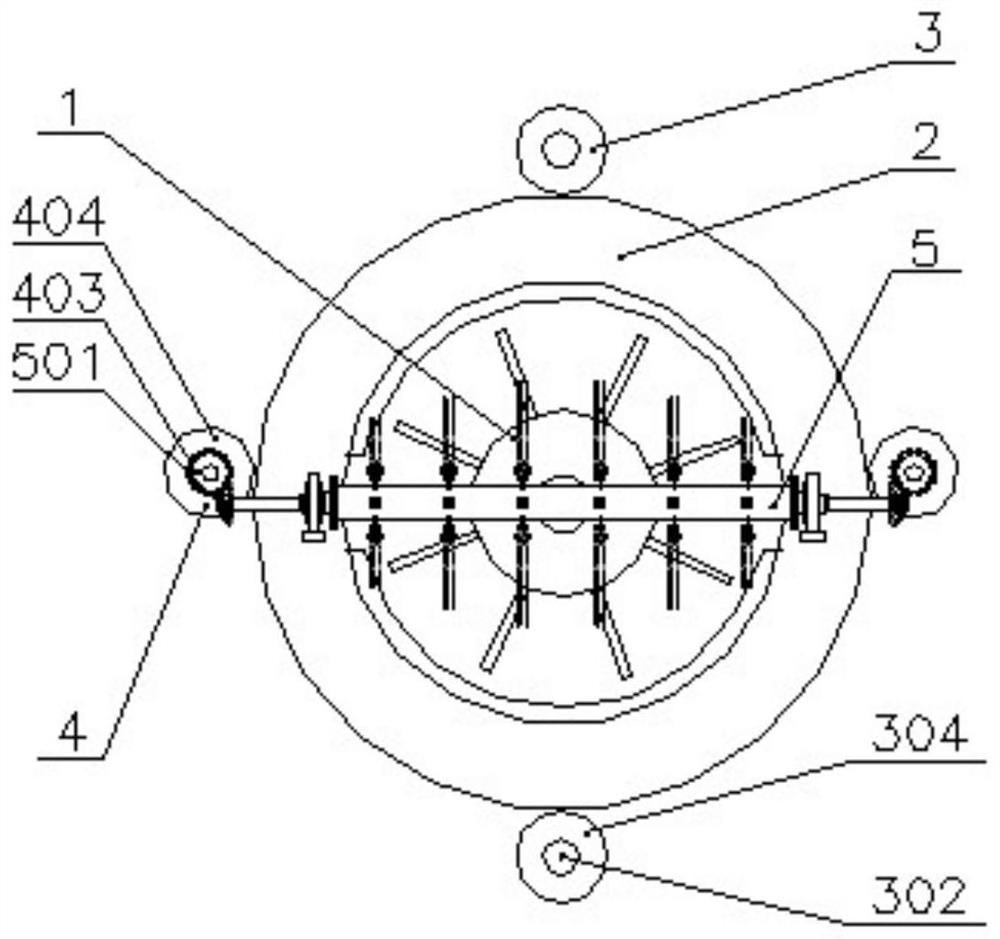

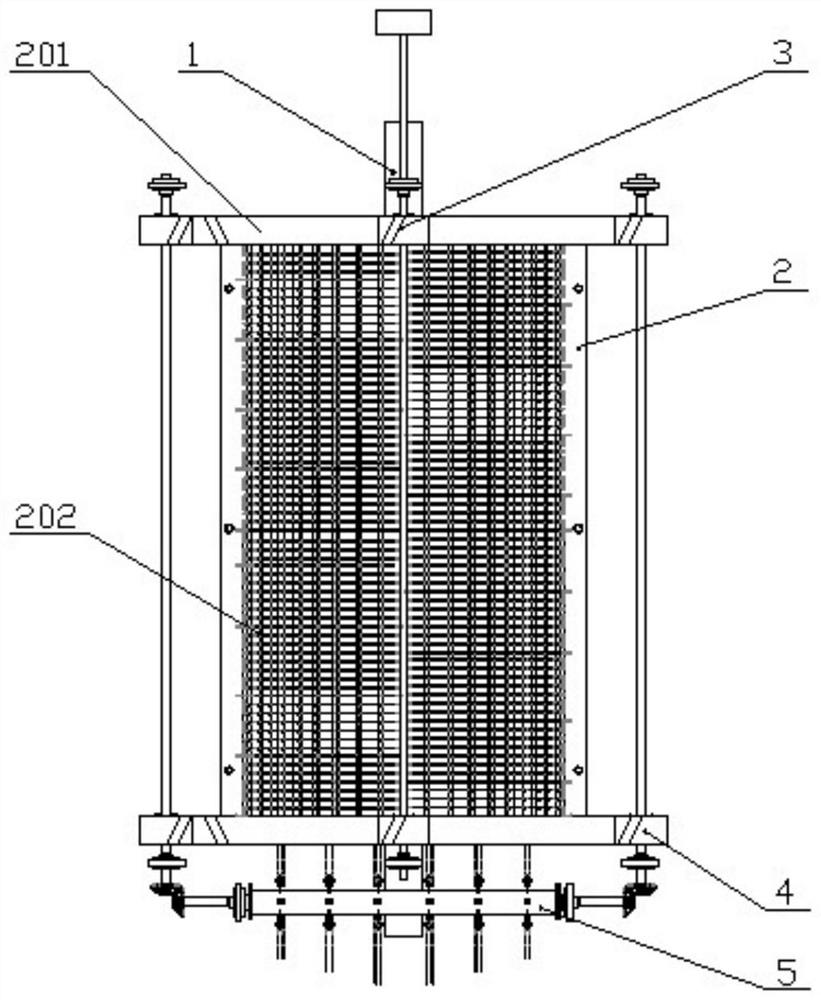

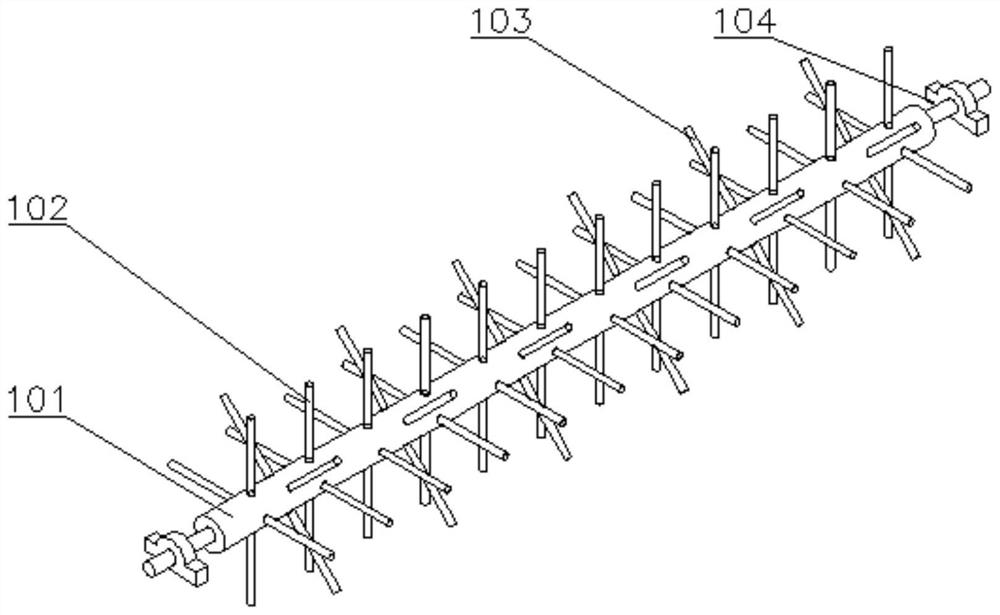

[0036] Such as figure 1 with figure 2As shown, the high-speed centrifugal threshing device of the grain combine harvester of the present invention includes a stator drum 1, a rotary concave screen 2, a power input gear set 3, a transmission gear set 4 and a grass breaking device 5. The stator drum 1 penetrates the interior of the rotary concave screen 2 and is installed coaxially with the rotary concave screen 2; the power input gear set 3 includes a power input gear box 301, a transmission shaft A302 and a first helical gear 304 The power input gearbox 301 is provided with two parallel output ends, each of which is connected to the transmission shaft A302, and two first helical gears 304 are installed on each of the transmission shafts A302, and the first helical gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com