Flapping wing micro air vehicle based on triangular structure

A triangular structure and aircraft technology, which is applied in the field of micro-aircraft, can solve the problems affecting the overall performance of micro-aircraft, asymmetry of flapping motion, and difficulty in size optimization control, etc., and achieves easy assembly and maintenance, strong differentiability, and convenient mass production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further explained below in conjunction with the drawings and embodiments, but the following content is not intended to limit the protection scope of the present invention.

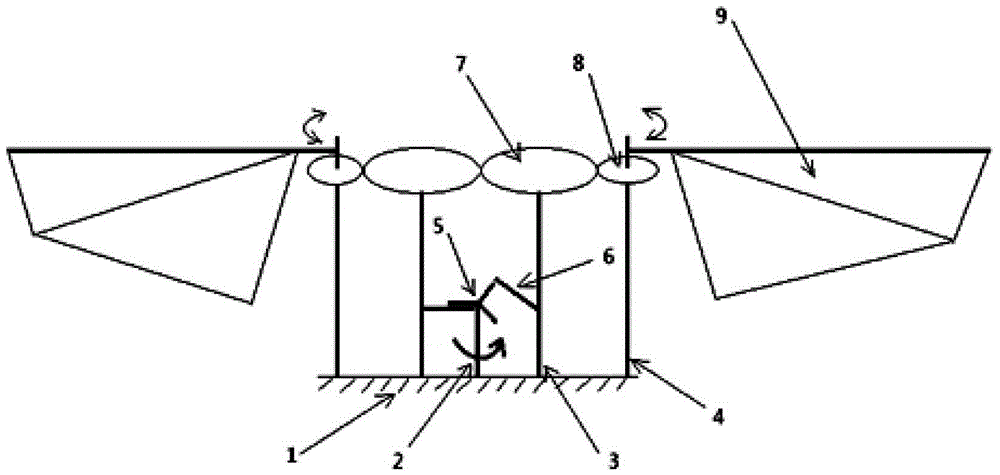

[0019] Such as figure 1 As shown, the present embodiment provides a novel flapping-wing micro-aircraft based on a triangular structure, including a frame 1, a motor output shaft 2, a first parallel shaft 3, a second parallel shaft 4, a triangular structure 5, a baffle plate 6, a large Gear 7, pinion 8 and wings 9, wherein: the frame 1 provides an overall frame for the whole micro-aircraft; the motor output shaft 2 transmits the motion of the motor to other parts; the first parallel shaft 3 and the triangular structure 5, The baffle plate 6 cooperates with the large gear 7 to convert the continuous rotation output by the motor into reciprocating rotation; the second parallel shaft 4 amplifies the amplitude of the reciprocating rotation of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com