Reducing take-up drafting device for braided fabric

A traction device and braided fabric technology, applied in the direction of braided fabrics, textiles and papermaking, etc., can solve the problems that the pressure roller cannot be retracted, and the braided fabrics with different diameters cannot be retracted, so as to achieve uniform tension and expand the retracted wire The effect of specification range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

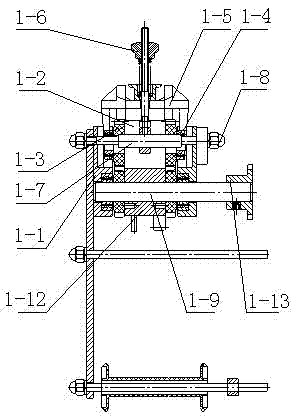

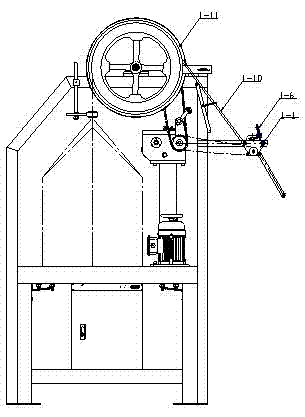

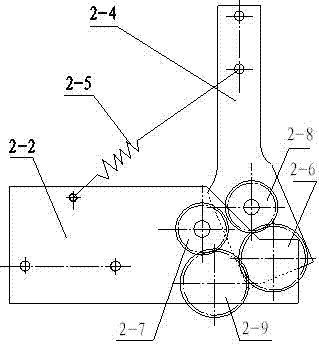

[0022] Embodiment 1: The traction device includes: active pinch wheel 2-1, active pinch wheel frame 2-2, passive pinch wheel 2-3, passive pinch wheel frame 2-4, extension spring 2-5, first gear 2- 6. Driving gear 2-7, driven gear 2-8, second gear 2-9, pinch wheel frame fulcrum shaft 2-10, driving shaft 2-13 and driven shaft 2-14; active pinch wheel frame and passive pinch wheel Each frame has two pieces, one end of the active pressure roller frame and the passive pressure frame are hinged through the fulcrum shaft of the pressure roller frame, and a tension spring is connected between the other end of the active pressure roller frame and the passive pressure frame; the driving shaft and the passive shaft are both passed through the bearing They are respectively connected between the two pressure roller frames of the active roller frame and the passive roller frame. There are active rollers on the driving shaft, passive rollers on the passive shaft, and outside of the active rol...

Embodiment 2

[0030] Embodiment 2: The transmission mechanism is a hybrid transmission of gear transmission and sprocket wheel.

[0031] The sprocket transmission includes: chain 2-15, transition sprocket 2-16, driving sprocket 2-17, driven gear 2-8 and second gear 2-9; driving sprocket 2-17 passes through chain 2- 15 is connected with the transition sprocket 2-16, the driven gear 2-8 meshes with the second gear 2-9, the driving sprocket 2-17 is connected with the driving shaft 2-13, and the driven gear 2-8 is connected with the driven shaft 2- 14, the transition sprocket 2-16 and the second gear 2-9 are tightly connected and run synchronously.

[0032] Others are the same as in Example 1.

Embodiment 3

[0033] Embodiment 3: The transmission mechanism is a hybrid transmission of gear transmission and belt.

[0034] The belt transmission is rack belt transmission or belt transmission, including: belt 2-25, transition pulley 2-26, passive pulley 2-28, driving gear 2-7 and second gear 2-9; passive pulley 2 -28 is connected with the transition pulley 2-26 through the belt 2-25, the driving gear 2-7 meshes with the second gear 2-9, the driving gear 2-7 is connected on the driving shaft 2-13, and the passive pulley 2-28 is connected on On the driven shaft 2-14, the transition pulley 2-26 and the second gear 2-9 are fastened and connected to run synchronously.

[0035] Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com