Stick-shaped motor stator fixing structure with axial pretension force

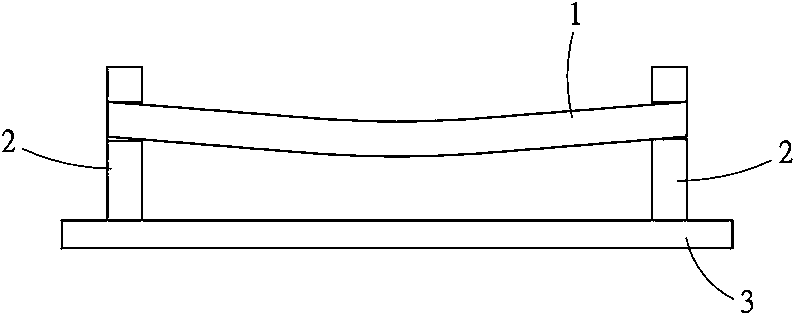

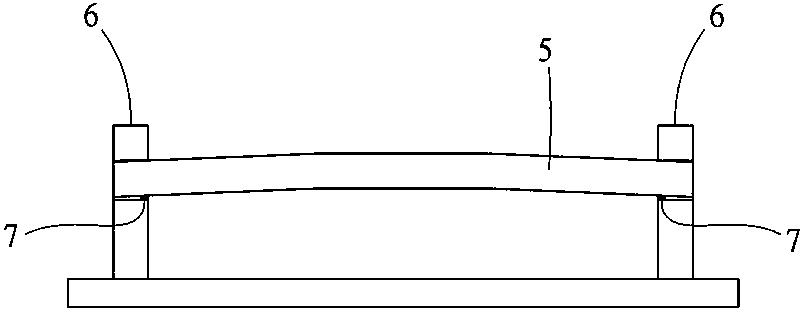

A motor stator, pre-tension technology, applied in the magnetic circuit shape/style/structure, magnetic circuit static parts and other directions, can solve the aggravated interference situation, cannot further ensure the straight extension state of the stator 5, and the inaccurate way of the contact state, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

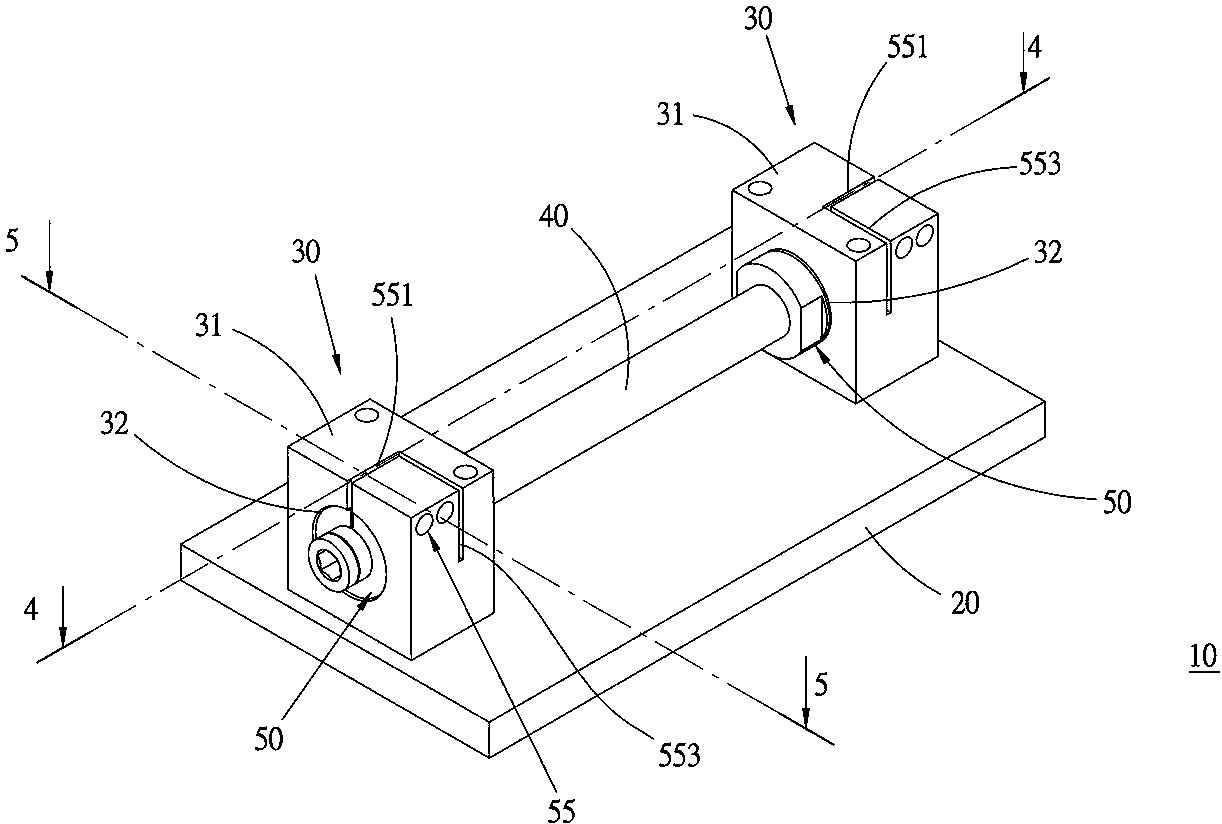

[0018] Hereinafter, a preferred embodiment of the present invention will be cited and further described in conjunction with the accompanying drawings.

[0019] see Figure 3 to Figure 5 As shown, the rod-shaped motor stator fixing structure 10 with axial pretension provided in a preferred embodiment of the present invention includes a base 20 , two abutments 30 , a stator 40 and a pretension group 50 .

[0020] The base 20 is generally in the shape of a rectangular plate and is used as a basis for other components.

[0021] Each of the plinths 30 is spaced apart from each other and is respectively arranged on the two ends of the long axis of the upper side seat surface of the base, and is symmetrical to each other, and has a block-shaped seat body 31, which is attached and fixed on the bottom side end surface. On the base 20 , a fixing hole 32 runs through the seat body 31 , and makes the fixing holes 32 of the podiums 30 coaxially correspond to each other.

[0022] The stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com