Band saw blade manufacturing method and band saw blade

A manufacturing method and technology for band saw blades, which are applied in the direction of tool manufacturing, manufacturing tools, metal sawing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

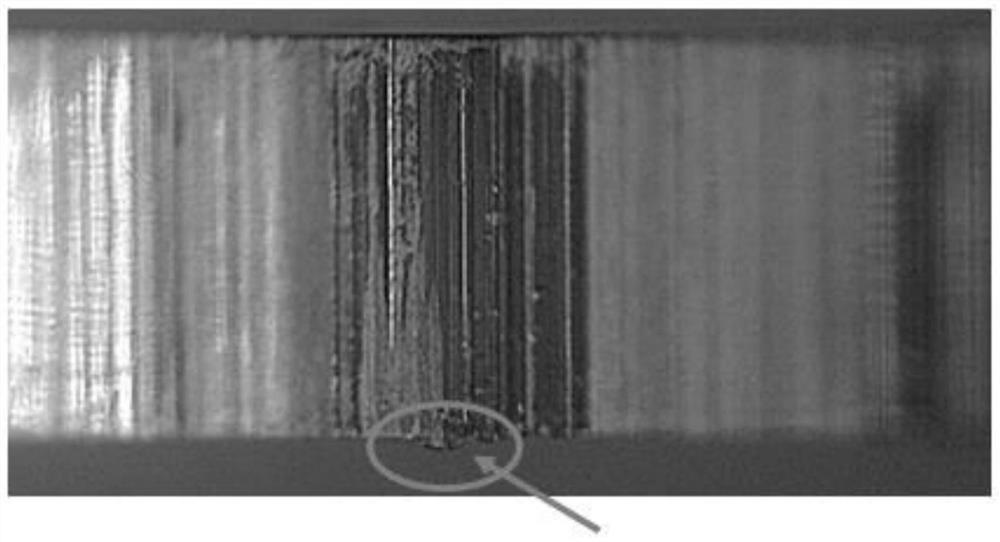

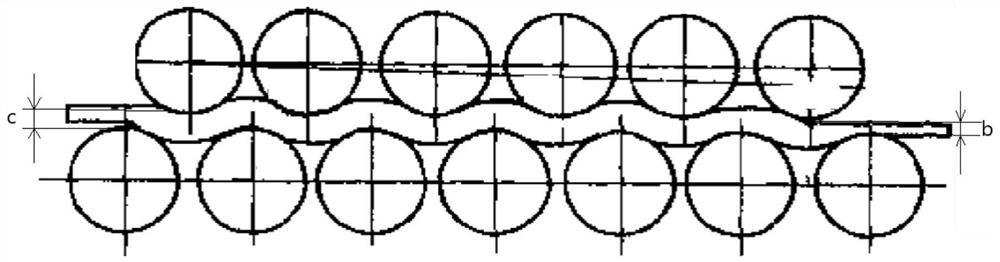

[0042] Using the method of the present invention to level and straighten the 67*1.6-1 / 1.5TPI specification band saw blade after 1000m tooth milling, the inlet gap is 0.5mm, the outlet gap is 1.6mm, and the inlet gap is 31% of the outlet gap. After leveling and straightening, the surface temperature rises by 40°C, and the knife bend is 0.3mm / 1000mm. Then carry out the processing of teeth dividing, cleaning, quenching and tempering processes, the average back of the band saw blade after processing is 0.028mm, the maximum value is 0.05mm, and the qualified rate is 100% (the qualified standard is 0.07mm). The difference between the maximum value and the minimum value of the amount of teeth is 0.03mm.

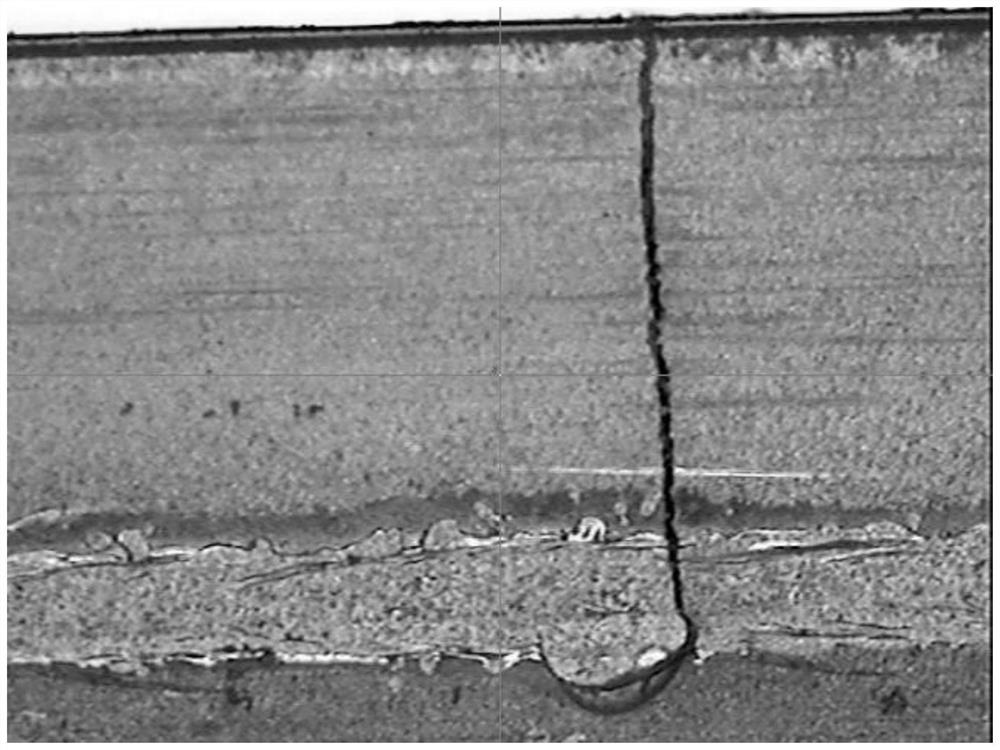

[0043] The bimetallic band saw blade processed by the above method is characterized by the turtle back Image 6 As shown, the sawtooth has no side burrs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com