Process production system used for stator coil insulation

A production system and stator coil technology, applied in laying solid insulation and other directions, can solve the problems of low production efficiency, poor product quality and high production cost of stator coil insulation, and achieve the effects of optimizing production organization, simple structure, and reducing bumps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

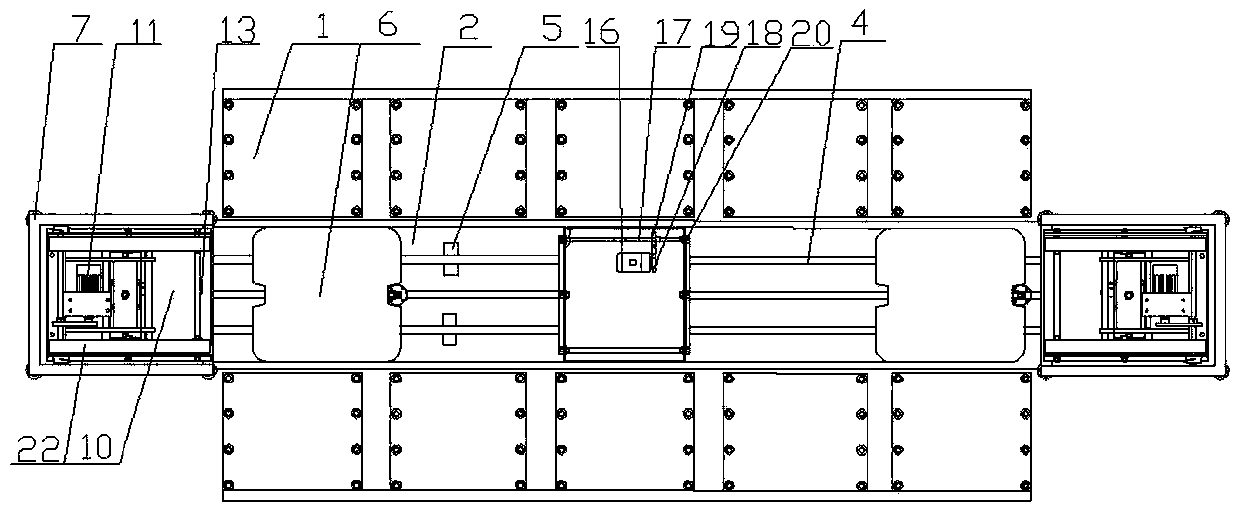

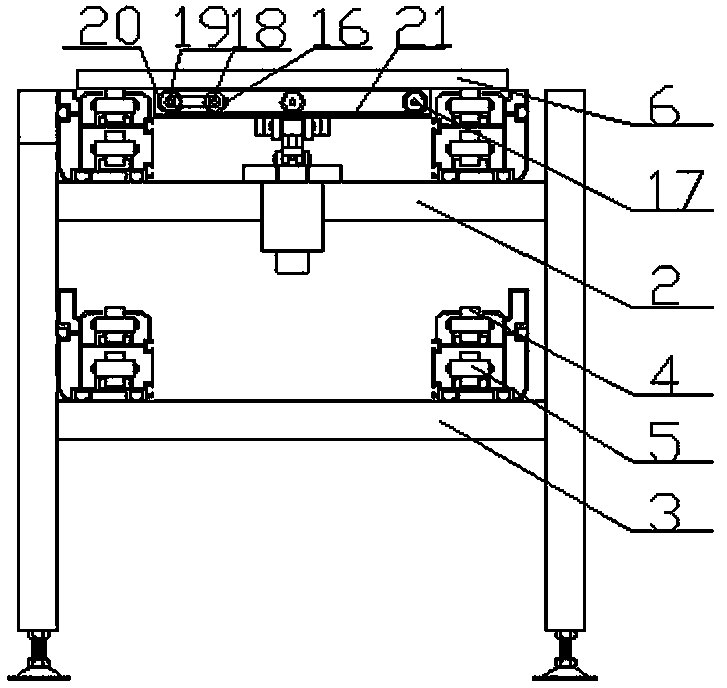

[0012] A process production system for stator coil insulation, including a double-layer support and several dressing tables 1 fixed on both sides of the double-layer support; the double-layer support includes an upper horizontal plate 2 and a lower horizontal plate below the upper horizontal plate 2 plate 3; the upper and lower transverse plates 2 and 3 are respectively supported with roller combinations 5 covered with transmission chains 4 in opposite directions of movement, and several pallets 6 are placed on the transmission chains 4; In the lifting device that tray 6 is transported up and down between the upper and lower horizontal plates 2,3 of the double-layer support, the upper horizontal plate 2 is provided with several transfer devices for moving the tray 6 to the dressing table 1 .

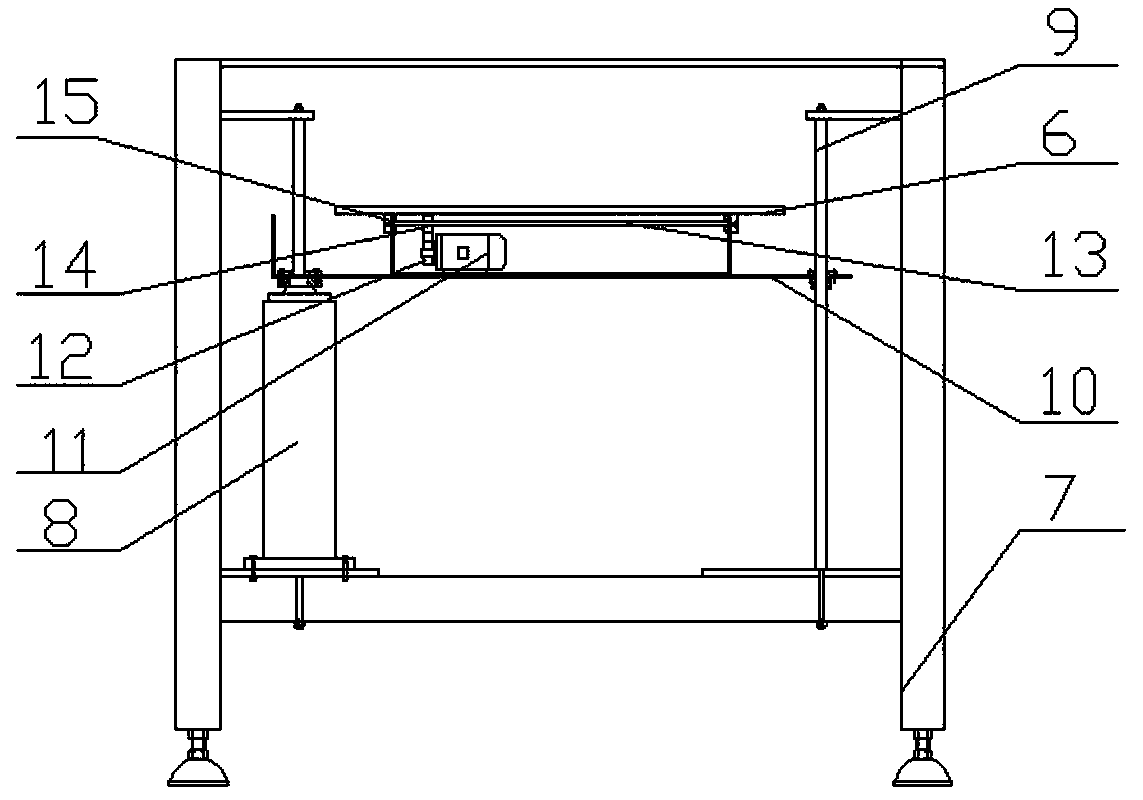

[0013] In specific implementation, such as figure 2 As shown, the lifting device includes a lifting bracket 7 fixed at the end of the double-layer bracket, a wind pressure cylinder 8 ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com