Tail breaking tool of turbine guider

A turbine guider and tool technology, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problem that ordinary calipers cannot accurately control the amount of deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with reference to the accompanying drawings and examples.

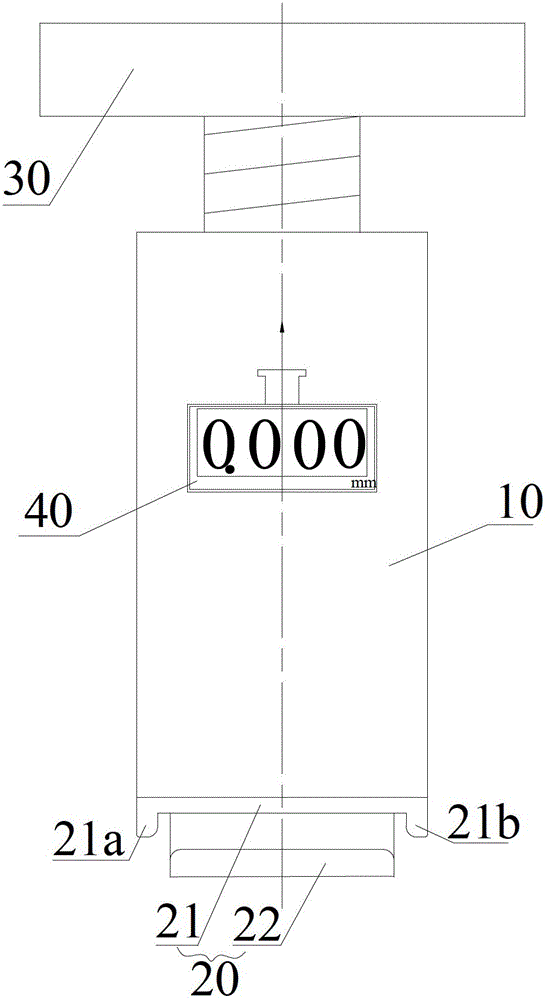

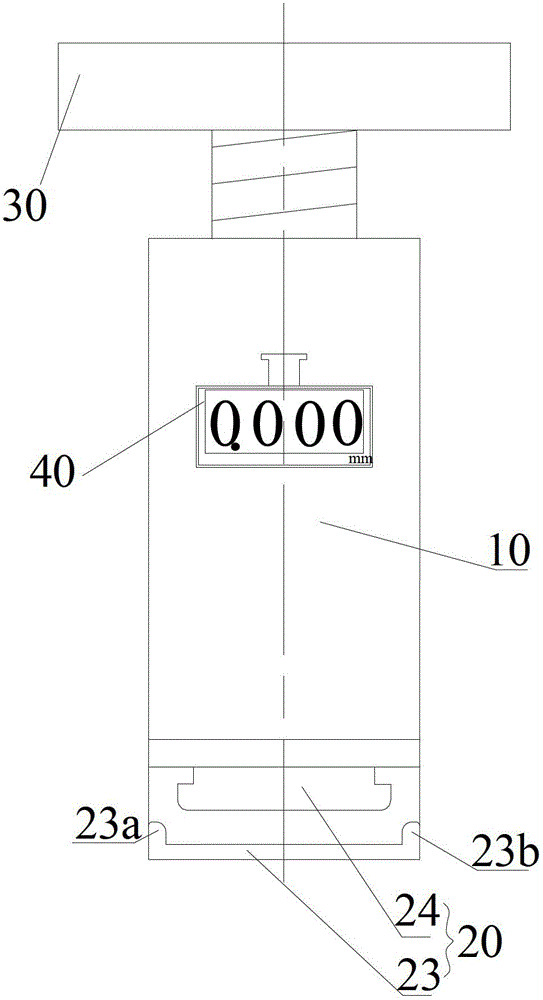

[0017] Such as figure 1 As shown, according to the first embodiment of the present invention, the tail breaking tool of the turbine guider includes a fixing sleeve 10, a tail breaking jig 20 provided at the first end of the fixing sleeve 10, and a tail breaking jig 20 arranged at the second end of the fixing sleeve 10 so as to break off the tail. The rotary mechanism 30 clamped by the tail clamp 20 ; the digital displacement measuring device 40 for measuring and displaying the clamping amount of the tail clamp 20 is also provided on the fixed sleeve 10 . The tail breaking tool of the turbine guider of the present invention, by setting the digital displacement measuring device 40 on the fixed sleeve 10 to measure and display the clamping amount of the tail breaking fixture 20, can be clamped according to the tail breaking fixture during the tail breaking op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com