Nut skirt automatic lock riveting machine

An automatic locking and nut technology, which is applied in the field of automatic locking and riveting of skirts, to achieve the effect of ensuring the tightening and anti-loosening function, improving the manufacturing quality and the competitiveness of the product, and the position is accurate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

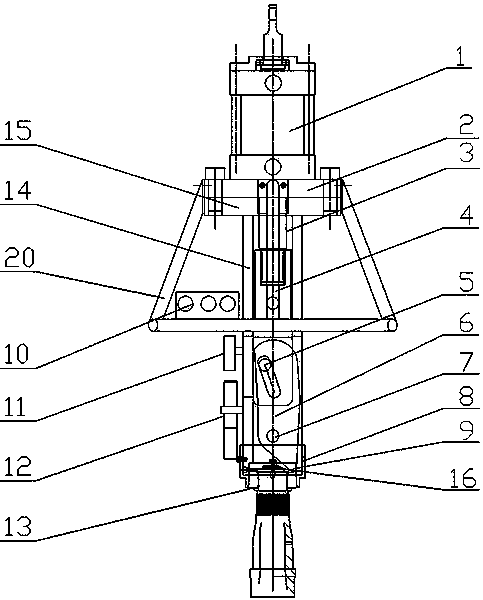

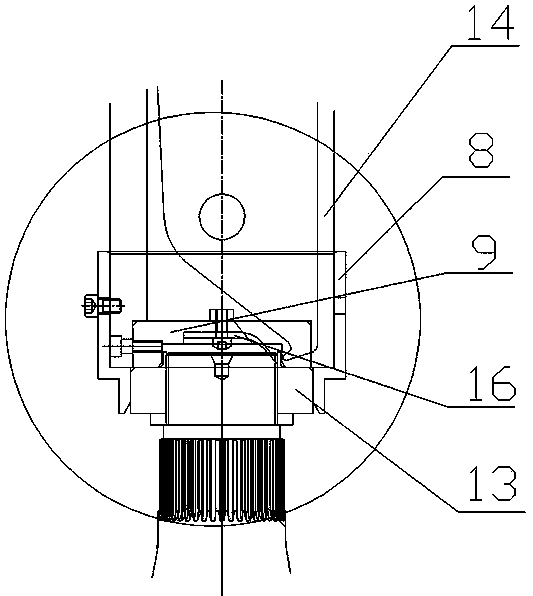

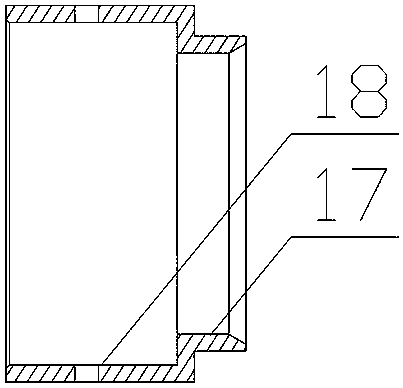

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 As shown, the connecting flange 2 under the oil cylinder of the gas-liquid supercharging mechanism 1 of the present invention is connected to the main body bottom plate 15 of the main body 14, the electric control button 10 is installed on the ring handle 20 of the main body 14, and the main body 14 is connected to the slide rail through a connecting piece . The piston rod 3 of the gas-liquid supercharging mechanism 1 is connected with the pull rod 4. The pull pin rod 5 is provided on the pull rod 4. The pull pin rod 5 penetrates into the chute of the lock riveting head 6. The axis of the chute and the axis of the pull rod 4 At an angle of 18° to 20°, the nut 13 is positioned in the positioning device. The present invention adopts the principle of gas-liquid pressurization through a gas source of 0.6Mpa to generate a pulling force of about 100KN in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com