Ball compensators for pipe connections

A compensator and pipeline technology, which is applied to expansion compensation devices for pipelines, pipes/pipe joints/pipes, pipe components, etc., and can solve the problem that the sealing ring is heavily loaded, cannot be installed and constructed, and the height of the overall structure is increased, etc. problems, to ensure the sealing effect, prevent liquid leakage, and achieve the effect of small installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

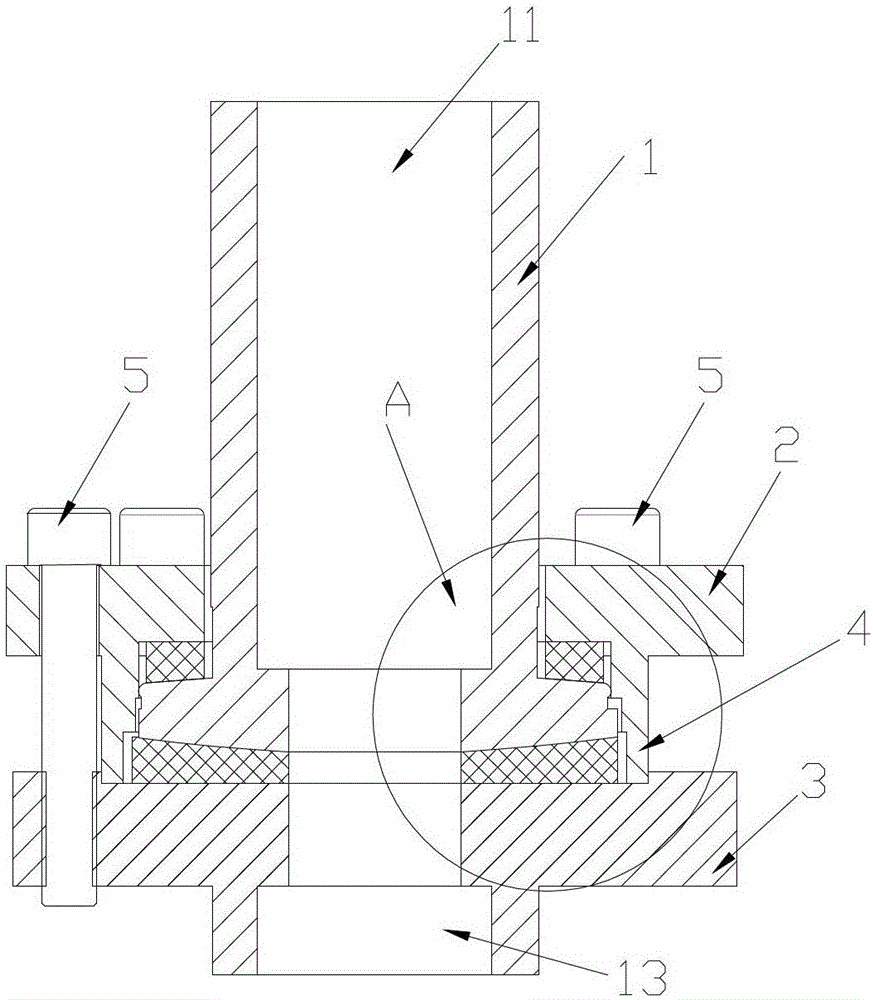

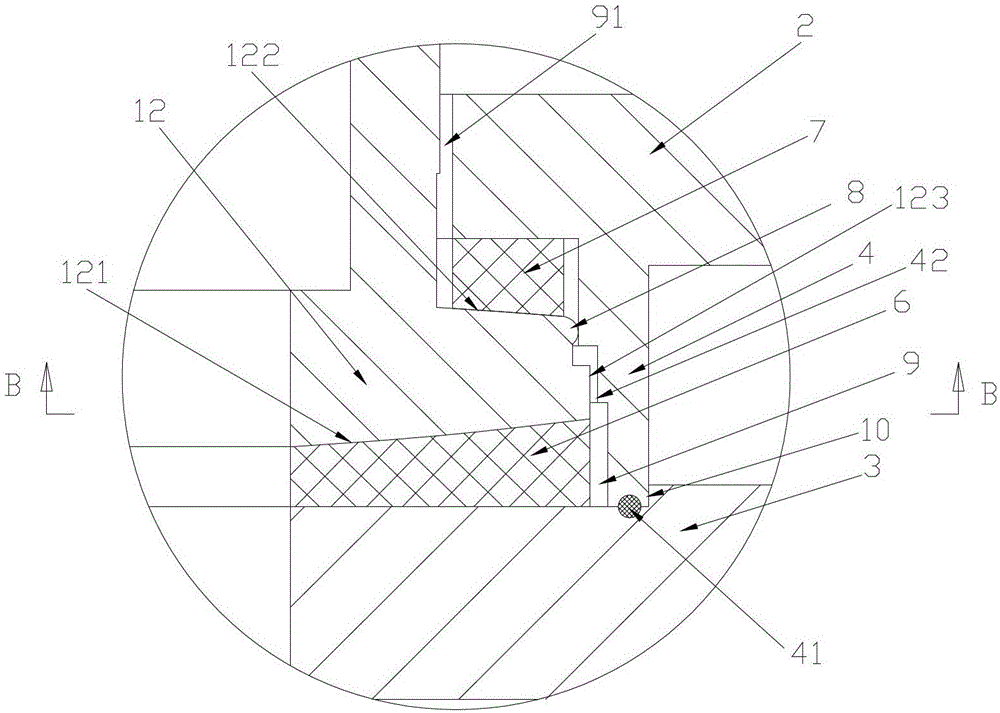

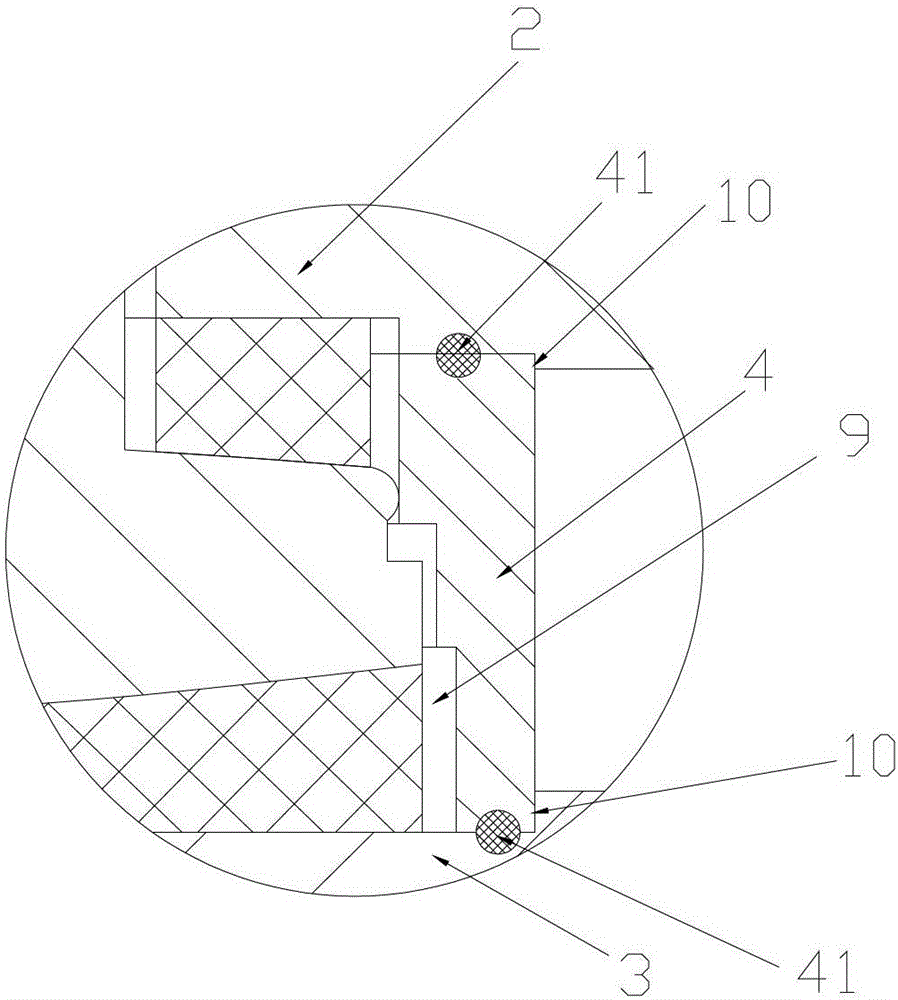

[0022] Such as figure 1 and figure 2 As shown, the spherical compensator used for pipeline connection includes a front pipeline 1 and a rear flange 3 which communicate internally, and the front channel 11 of the front pipeline 1 communicates with the rear channel 13 in the rear flange 3 . A spherical sealing ring 6 is arranged between the connecting end faces of the front pipe 1 and the rear flange 3 . The front pipe 1 is provided with a flange 12 whose outer diameter is larger than that of the front pipe 1 , and the connecting end surface of the front pipe 1 is arranged on the front end surface 121 of the flange. And the flange front end surface 121 is designed as a spherical surface matching the shape of the spherical sealing ring 6 to ensure that the front pipe 1 is in the axial swing mode, and the sealing between the flange front end surface 121 and the spheri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com