Tire clamping device of rotatable tire

A clamping device and tire technology, applied in tire installation, tire parts, wheel assembly and disassembly equipment, etc., can solve the problems of difficult tire disassembly, time-consuming and laborious, and inability to rotate tires, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

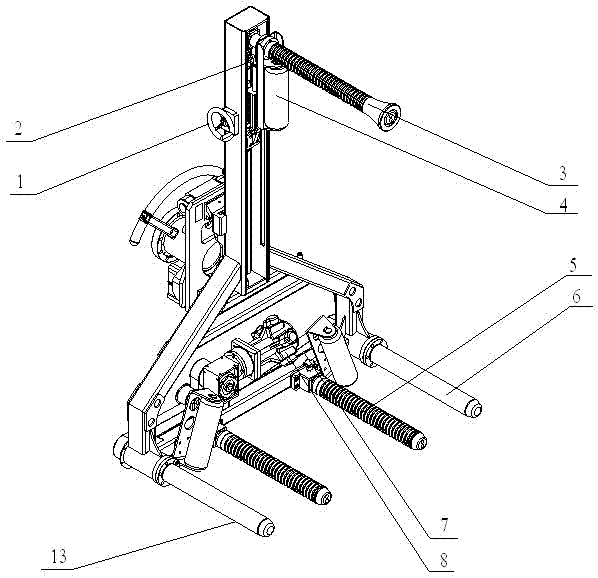

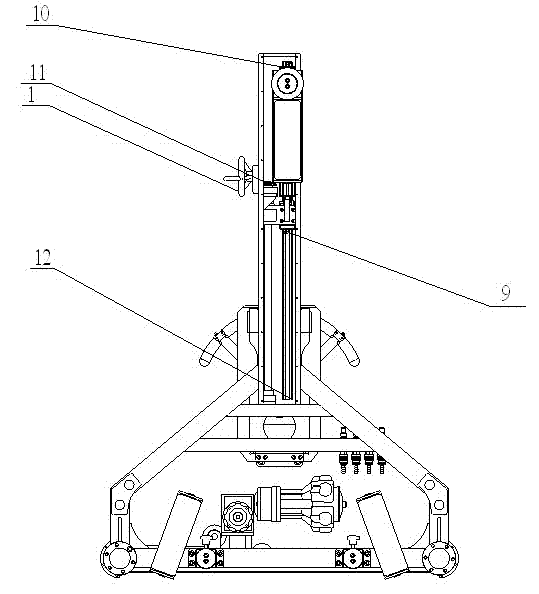

[0014] As shown in the figure, the tire clamping device for rotatable tires includes a base on which a drive assembly, a synchronous belt transmission device, a first support rod, a second support rod, jaws, a pneumatic clamping assembly and Clamp components manually.

[0015] The driving assembly is an air motor 8, and the synchronous belt transmission device 7 includes a synchronous pulley, a tensioner pulley and a synchronous belt. The air motor 8 and the synchronous belt transmission device 7 connect the first support rod 6 and the second support rod 13 and drive them to rotate. .

[0016] The pneumatic clamping assembly and the manual clamping assembly are connected with the jaws, the pneumatic clamping assembly includes the cylinder 2 and the lead screw 11, the manual clamping assembly includes the hand wheel 1 and the lead screw 11, the cylinder 2 and the clamping jaw 3 are connected and together with it Move on slide rail 12.

[0017] Clamping claw 3 is used for clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com