Equipment for dismounting and mounting axle of heavy machine

A technology for heavy machinery and axles, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of high labor intensity, low work efficiency, large volume, etc., to reduce labor intensity, improve work efficiency, and improve assembly efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

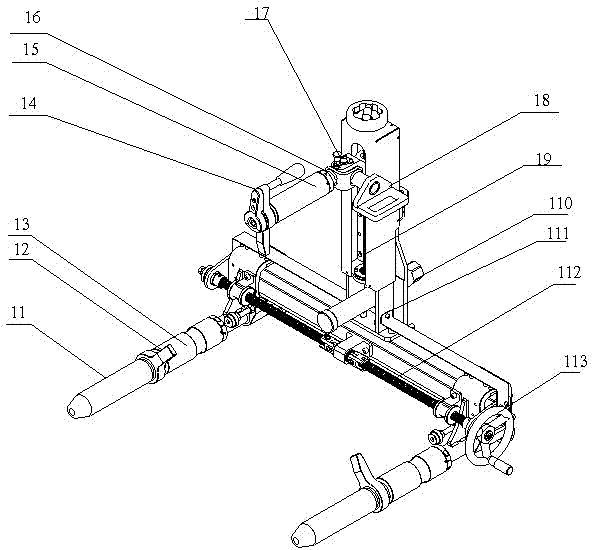

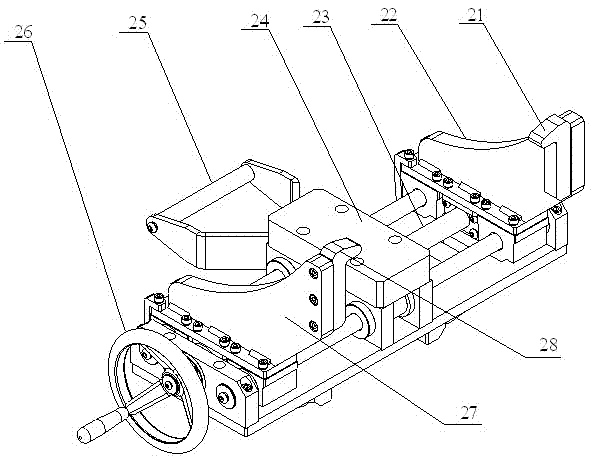

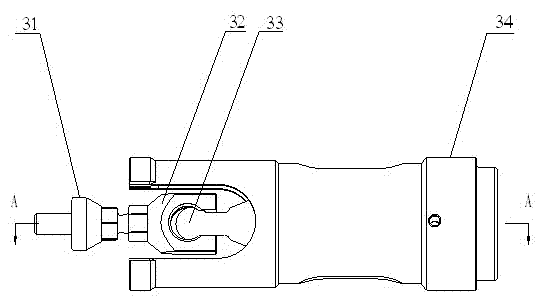

[0041] As shown in the figure, the equipment for disassembling and assembling heavy machinery axles includes crawler wheel train fixtures, balance elbow fixtures, torque shaft pullers, tire fixtures, pneumatic tool holders, and mechanical wrists for disassembling and assembling axles;

[0042] Such as figure 1 As shown, the track wheel train fixture includes a base, on which a left support bar assembly and a right support bar assembly, a support bar adjustment device, a driving wheel road wheel jaw assembly, a lifting device and a road wheel head are arranged on the base,

[0043] The left support rod assembly and the right support rod assembly respectively include the rotating hook 2, the auxiliary supporting rod 1 at the front end of the rotating hook 2, and the first adjustment and positioning device 3 located in the middle section of the rotation hook. The first adjustment and positioning device 3 is made of steel Ball bushing. The supporting rod adjusting device comprise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com