Four-edge sealing mould for packaging film

A packaging film, four-side sealing technology, applied in packaging sealing/fastening, packaging, transportation packaging, etc., can solve the problem of difficult alcohol stability and effectiveness, unsatisfactory sealing performance of alcohol cotton pads, product air leakage and water leakage, etc. problems, to achieve the effect of maintaining long-term stability and effectiveness, excellent packaging sealing, and avoiding air leakage and water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

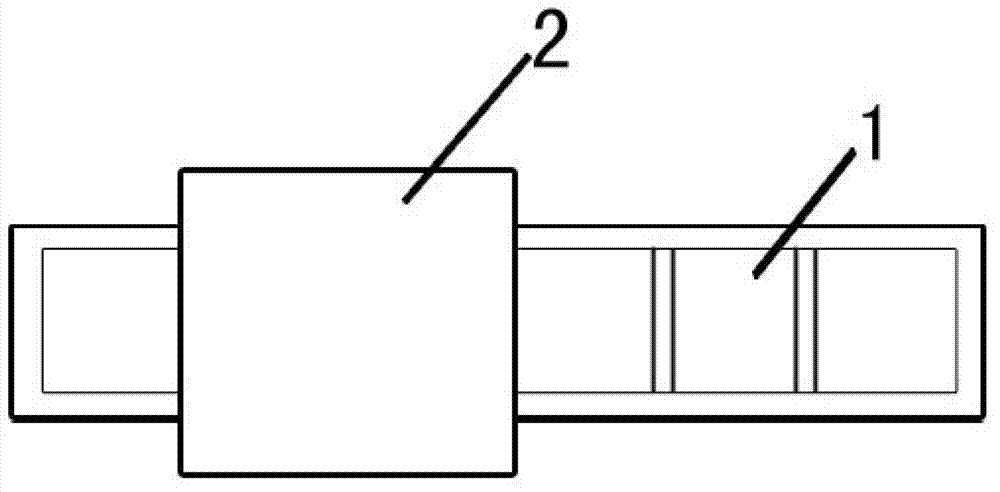

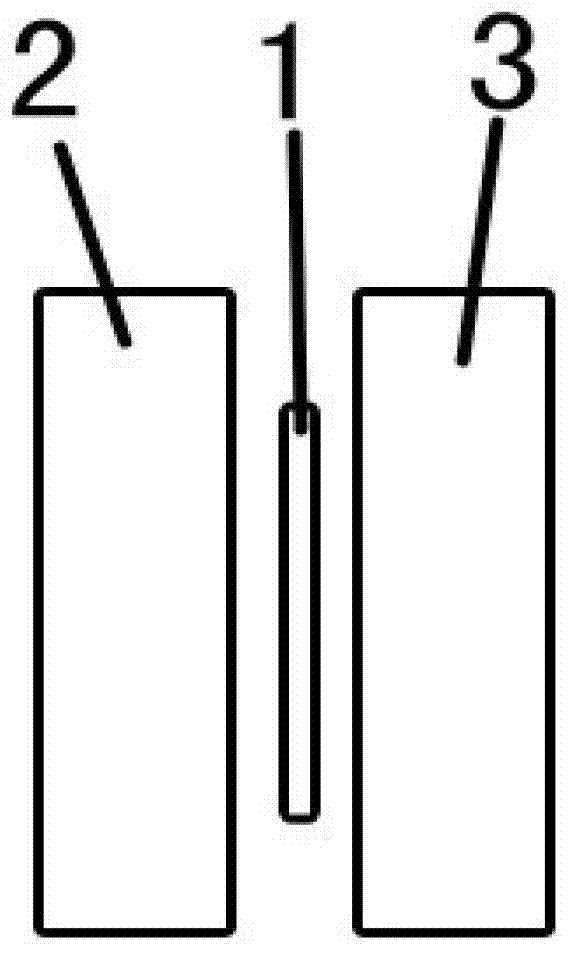

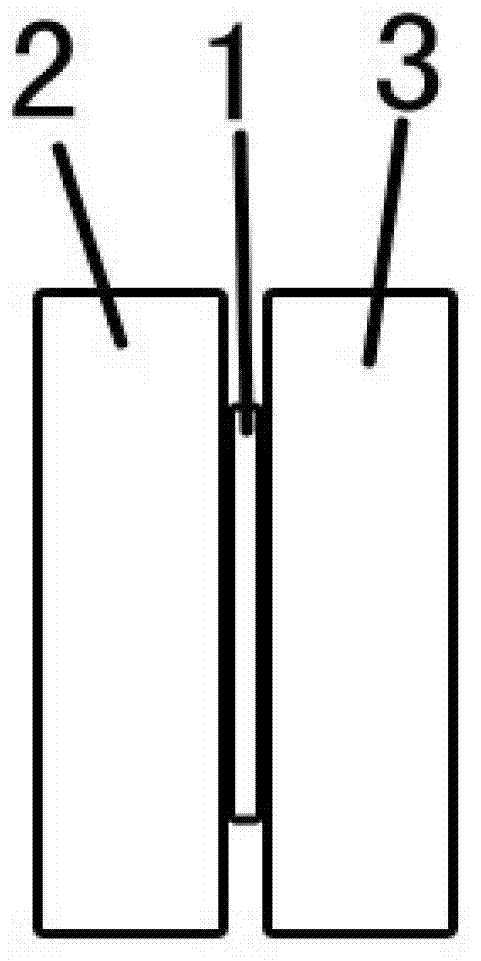

[0016] as attached figure 1 , 2 The edge sealing mold of a kind of four-side sealing packaging film of the present invention shown in , 3 comprises front heating module 2, back heating module 3; a heating device (not shown); the back heating module 3 is provided with a heating device (not shown) corresponding to the front heating module 2; when the front heating module 2 and the back heating module 3 sandwich the packaging film 1 , the four sides of the packaging film 1 can be effectively bonded at one time to make it more sealed; in this embodiment, the heating device arranged on the front heating module can be square, circular or oval.

[0017] The edge sealing mold of the four-side sealing packaging film of the present invention can seal the four sides of the packaging film more tightly and firmly through the double-sided heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com