Gear shifting control method of mechanical automatic transmission

A technology of automatic transmission and control method, which is applied in the direction of transmission control, mechanical equipment, components with teeth, etc., can solve the problem of missing engine power or economical shift work points, etc., and achieve perfect control methods and functions, The effect of improving economy and power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

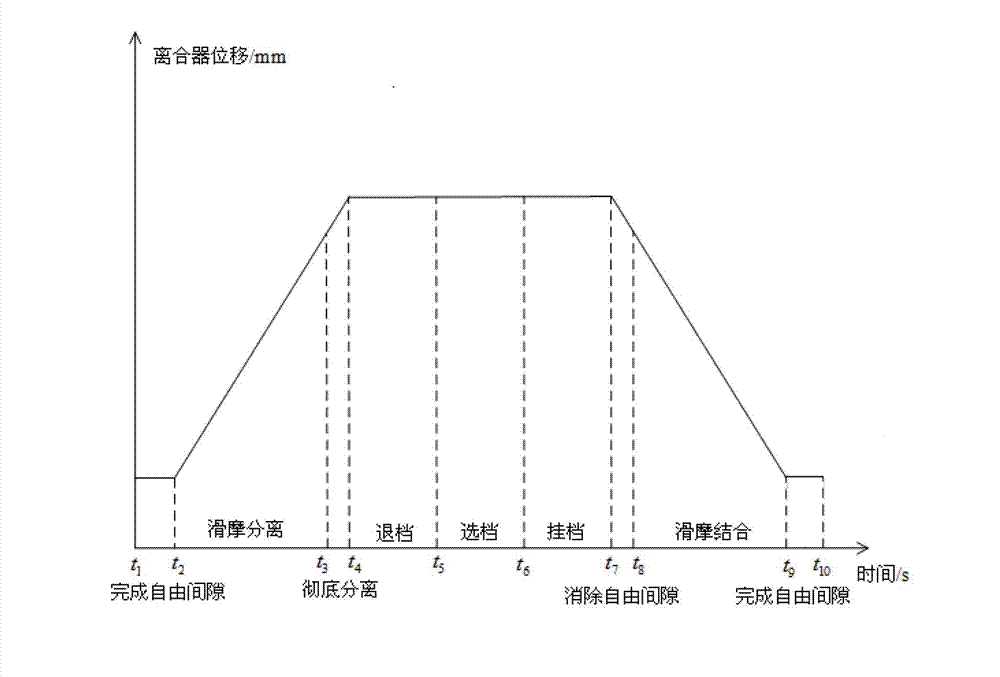

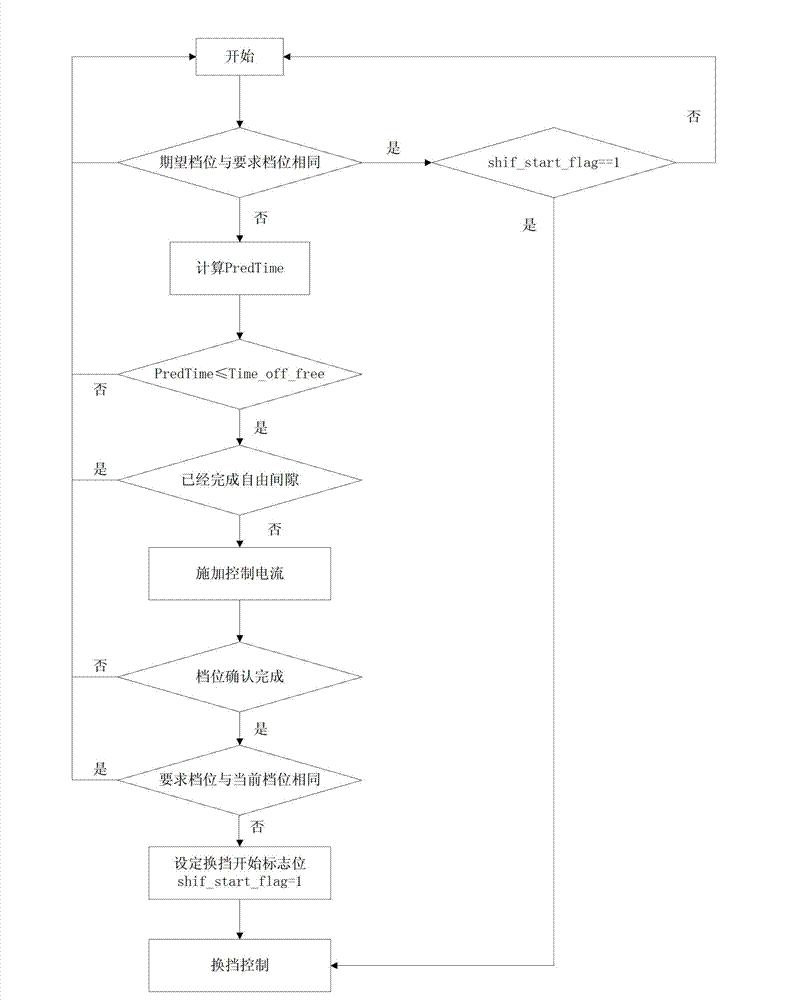

[0025] The invention aims to solve the problem that the car misses the best shifting working point due to mechanical delay when shifting gears, and proposes a shifting control method that controls the actuator to complete the free gap in advance. The technical scheme of the present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

[0026] Technical scheme of the present invention is as follows:

[0027] The invention proposes a shift control method of an electronically controlled mechanical automatic transmission. Before the method is implemented, the time Time_off_free required by the clutch actuator to complete the free gap can be obtained according to the inherent characteristics of the vehicle, and this time exists as a fixed value in the control method. The steps of the control method are:

[0028] Step 1, the control method detects the vehicle speed and the acceleration of the vehicle in real time;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com