Filter screen cleaning device and indoor air conditioning unit

An air-conditioning indoor unit and cleaning device technology, applied in the field of air-conditioning, can solve the problems that impurities cannot be completely and effectively removed, such devices cannot be installed, and the control method is cumbersome, etc., and achieve low cost, small size, and good adsorption reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

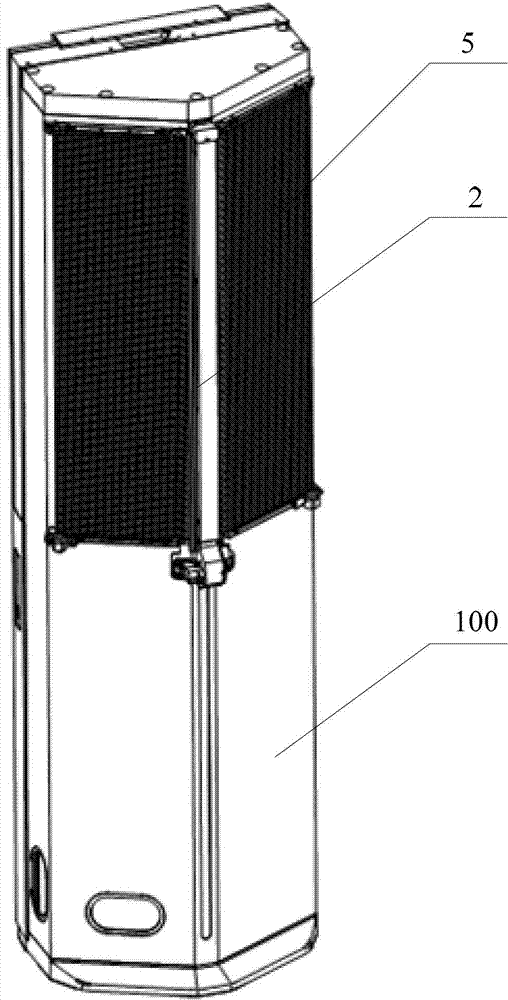

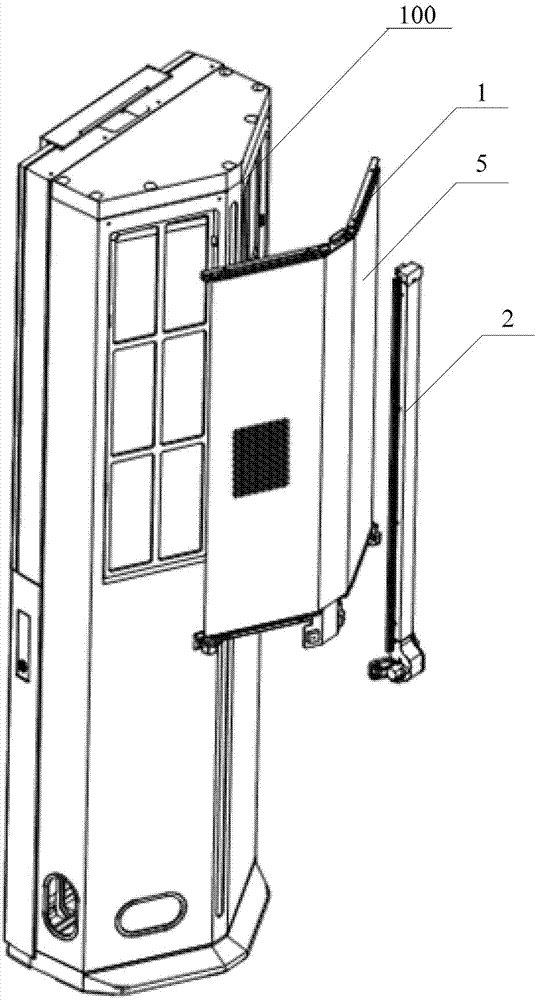

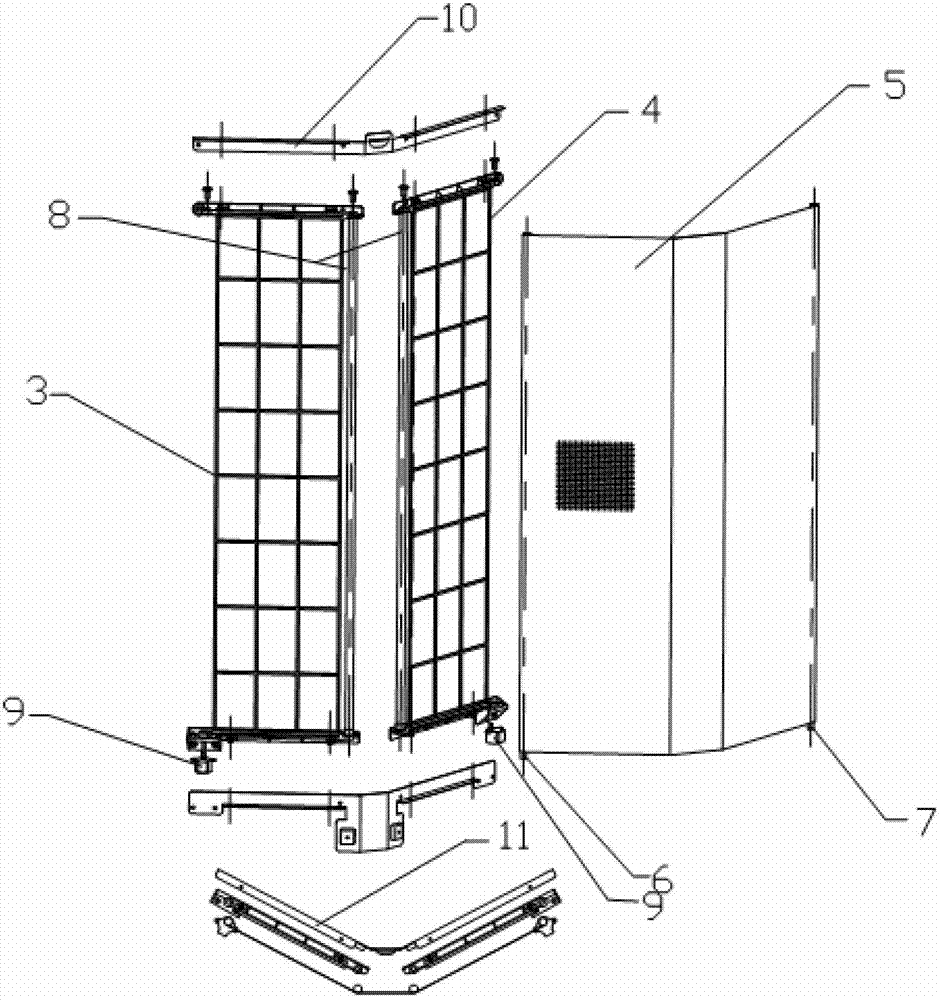

[0048] Please refer to figure 1 and figure 2 , figure 1 It is a schematic diagram of the overall structure of an indoor unit of a cabinet air conditioner with a filter net cleaning device in an embodiment of the present invention; figure 2 yes figure 1 Schematic diagram of partial decomposition of the structure.

[0049] Such as figure 1 and figure 2 As shown, a filter cleaning device proposed in this embodiment is installed on the indoor unit body 100 of a cabinet air conditioner. The filter cleaning device includes: a filter 5, supporting the filter 5 and driving the filter 5 a movable filter mechanism 1 moving in the horizontal direction, and a dust suction mechanism 2 fixedly connected with the movable filter mechanism 1 for cleaning the filter 5 .

[0050] Wherein, the filter screen 5 is installed on the air inlet side of the air conditioner indoor unit body 100 through the movable filter screen mechanism 1, specifically installed on the back plate of the air inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com