Machine vision based detection method of defect of geometrical shape of back surface of E type magnet

A technology of machine vision and defect detection, which is applied in the field of image processing, can solve problems such as low detection efficiency, geometric defects on the back of E-shaped magnetic materials, and large amount of calculation, etc., to achieve small memory space, fast calculation speed, and small amount of calculation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

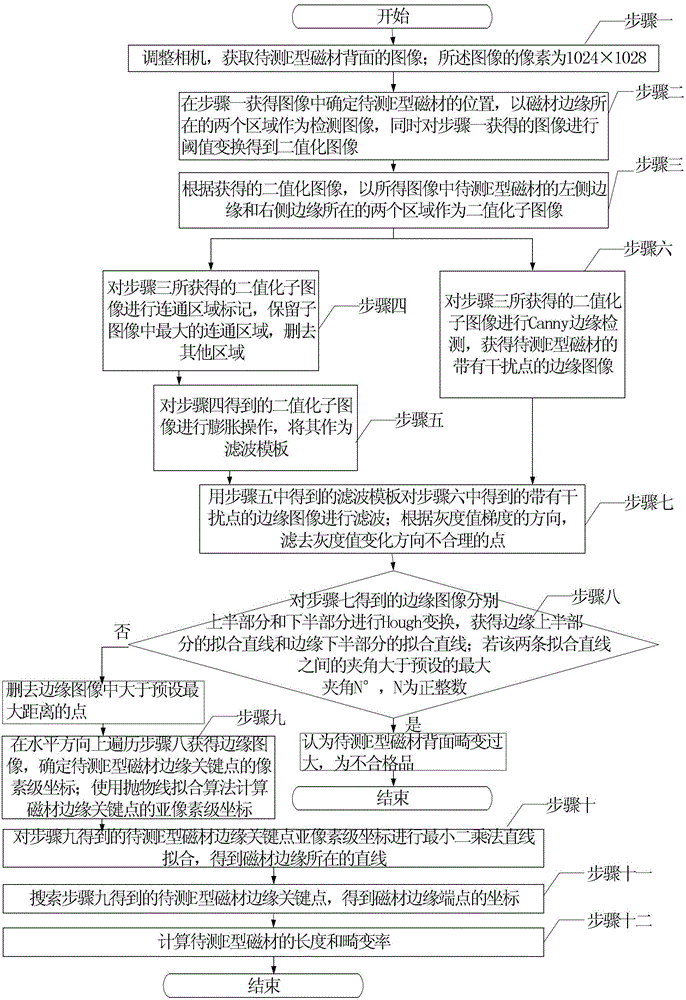

[0023] Specific implementation mode one, the following combination figure 1 Illustrate the present embodiment, the E-type magnetic material backside geometry defect detection method based on machine vision described in the present embodiment, it is realized by the following steps:

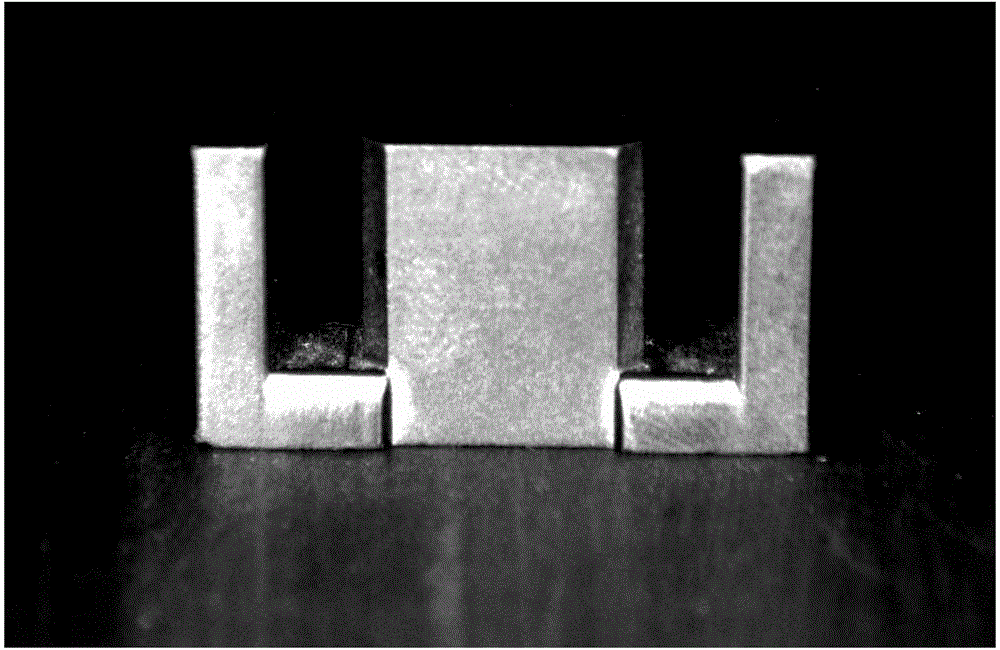

[0024] Step 1. Adjust the camera to obtain the image on the back of the E-shaped magnetic material to be tested; the pixel of the image is 1024×1028;

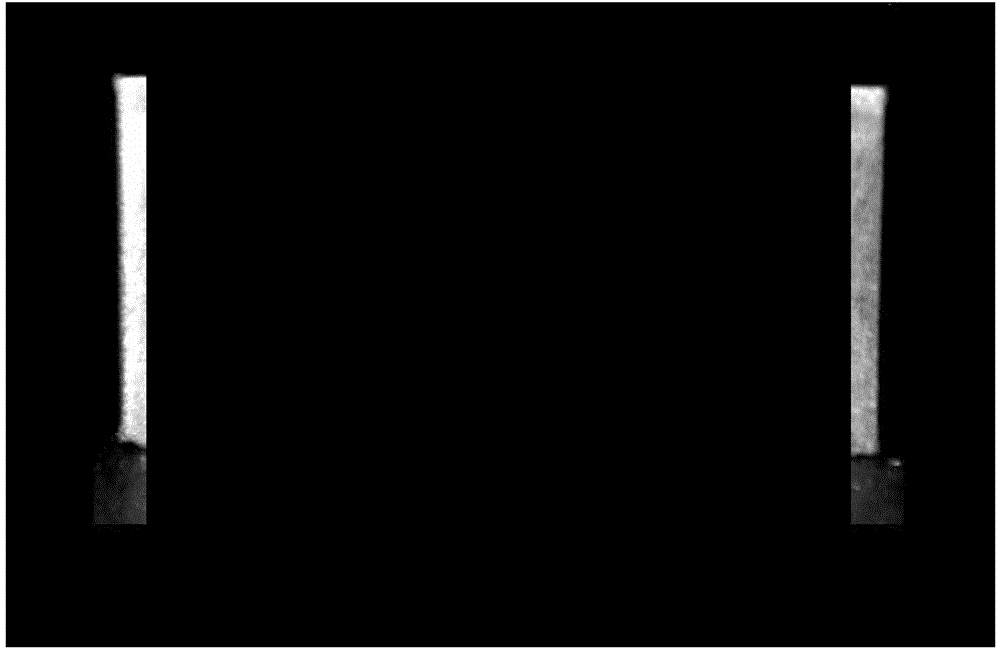

[0025] Step 2, determine the position of the E-shaped magnetic material to be tested in the image obtained in step 1, use the two regions where the edge of the magnetic material is located as the detection image, and simultaneously perform threshold transformation on the image obtained in step 1 to obtain a binary image;

[0026] Step 3. According to the obtained binarized image, the two areas where the left edge and right edge of the E-shaped magnetic material to be tested are located in the obtained image are used as binarized sub-images, and then...

specific Embodiment approach 2

[0040] Specific implementation mode two, the following combination figure 1 Describe this embodiment, this embodiment is a further description of Embodiment 1, the method for detecting geometric defects on the back of the E-shaped magnetic material based on machine vision described in this embodiment, the camera in the step 1 is equipped with a telecentric lens camera.

specific Embodiment approach 3

[0041] Specific implementation mode three, the following combination figure 1 Describe this embodiment, this embodiment is a further description to Embodiment 1, the E-shaped magnetic material backside geometric defect detection method based on machine vision described in this embodiment, in the described step 3, obtain the binary value according to the step 1 The image is used to determine the position of the E-shaped magnetic material to be tested, and the method for determining the position of the E-shaped magnetic material to be tested is:

[0042] Obtain the vertical coordinates of the upper and lower edges of the E-shaped magnetic material and the horizontal coordinates of the left and right edges, and use these four coordinate values to represent the position of the E-shaped magnetic material;

[0043] The method to obtain the ordinate of the upper edge and the lower edge of the E-shaped magnetic material is: project the binarized image onto the ordinate, the projecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com