Supporting base

A technology of supporting claws and discs, which is applied in vehicle maintenance, lifting vehicle accessories, transportation and packaging, etc., can solve problems such as poor adaptability to slope roads, rollover of engineering vehicles, etc., achieve strong mobility, expand support range, expand The effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

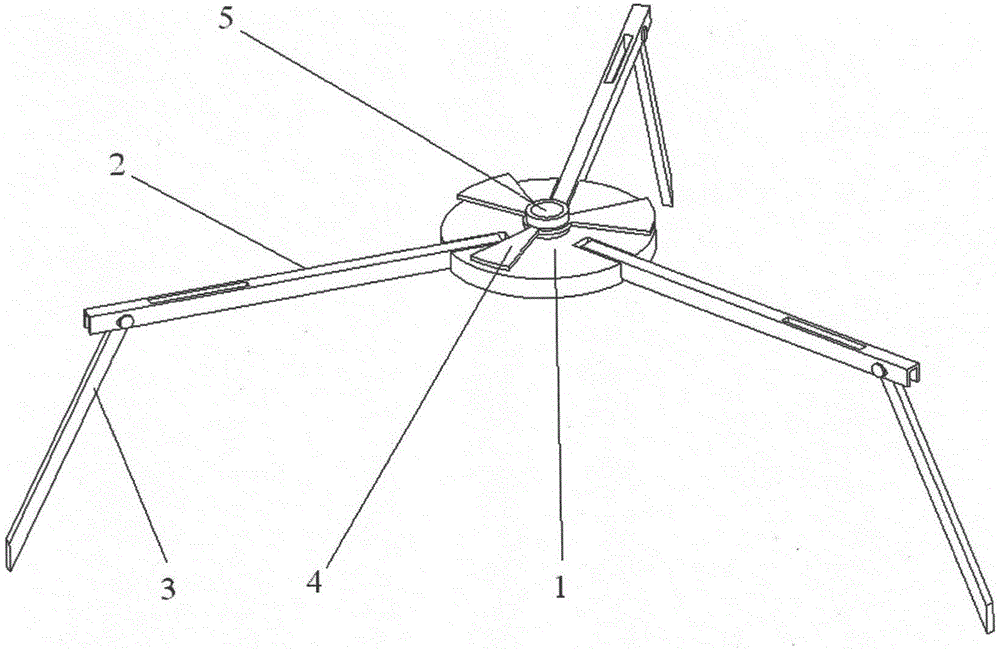

[0018] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

[0019] image 3 It is a schematic diagram of a support base provided by the present invention. The support base includes a central disc 1, and one end of three near support claws 2 is uniformly mounted on the central disc 1 through a hinge, and can be put down and folded. Among the three near support claws 2, one is longer than the other two, and is used to prevent the device from tilting.

[0020] The front end of the far support claw 3 is connected with the other end of the near support claw 2 by a hinge 8, and the first slider 9 is equipped with the hinge 8 front portion on the far support claw 3, and the second slider 9 is equipped with the hinge 8 front portion on the near support claw 2. The block 7, the first slider 9 and the second slider 7 are connected by a connecting rod 6. When positioning is required, the bolts 10 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com