Flame-retarded explosion-proof valve

An explosion-proof valve, internal flame retardant technology, applied in the direction of safety valve, balance valve, valve device, etc., can solve the problem of not completely extinguishing the flame, uneven pressure distribution, etc., to achieve the effect of releasing pressure, reducing airflow temperature, and reducing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Further illustrate the present invention below in conjunction with accompanying drawing

[0025] Referring to the attached picture:

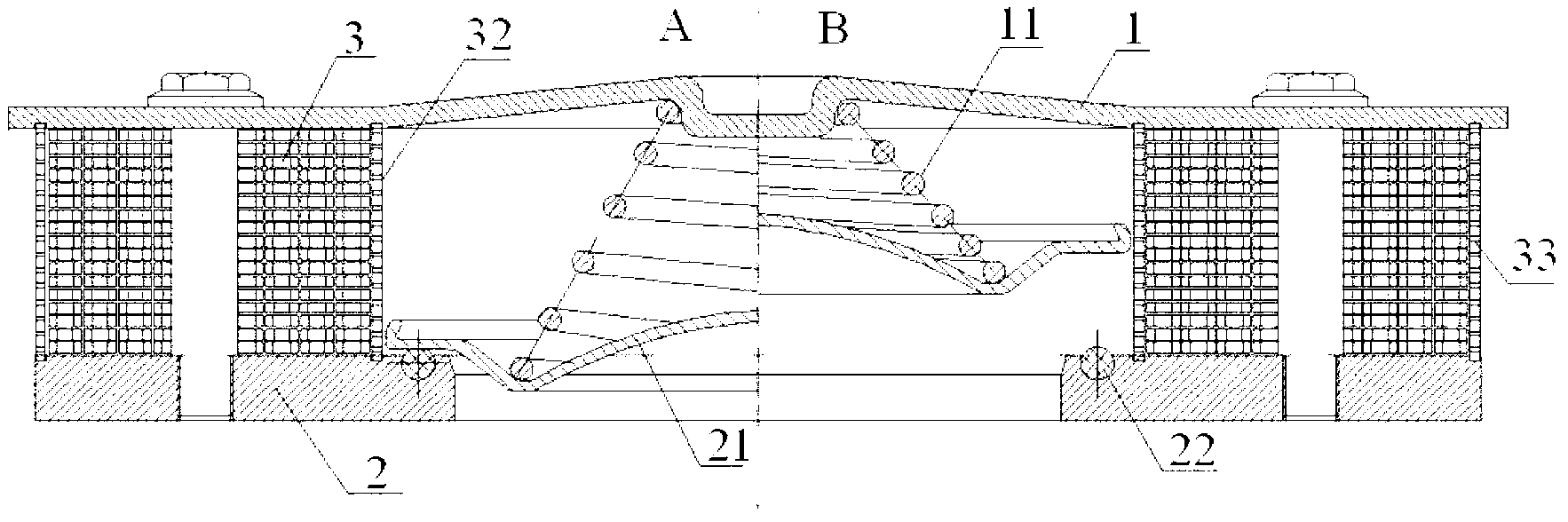

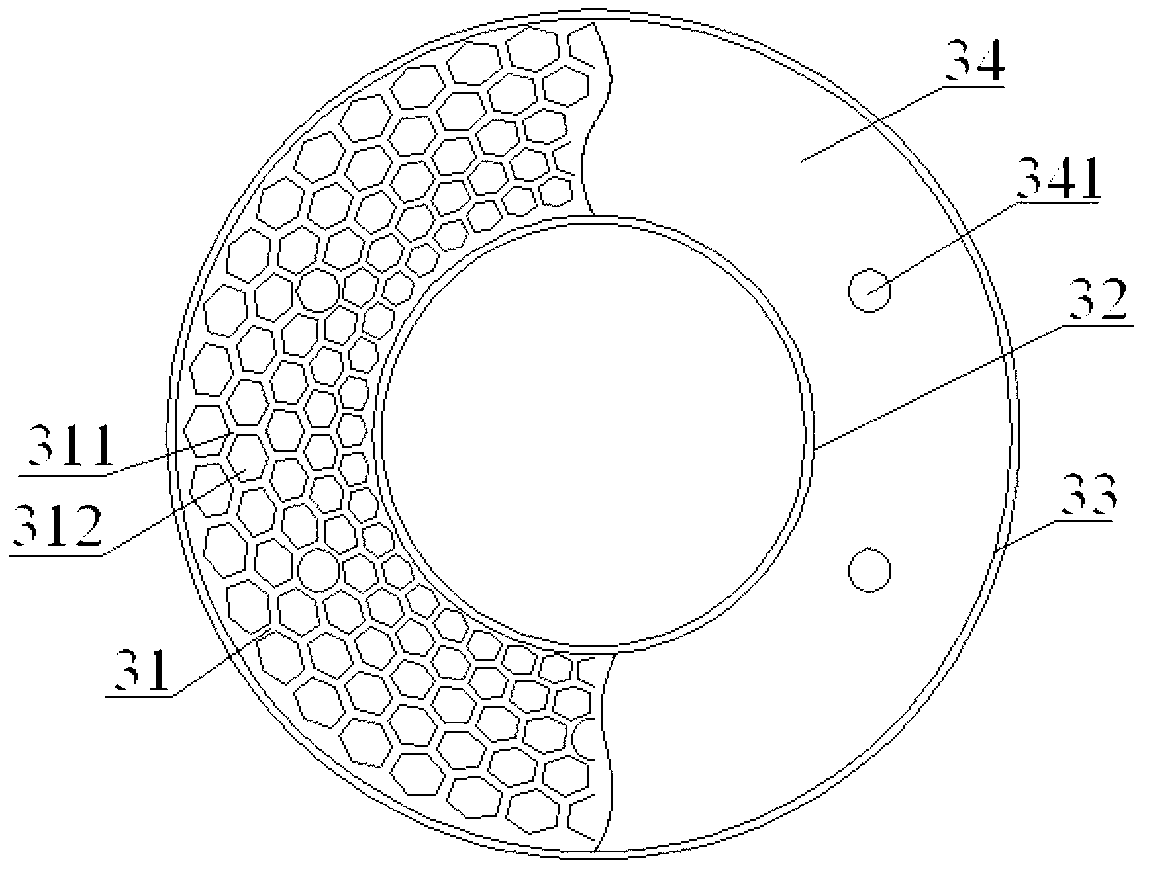

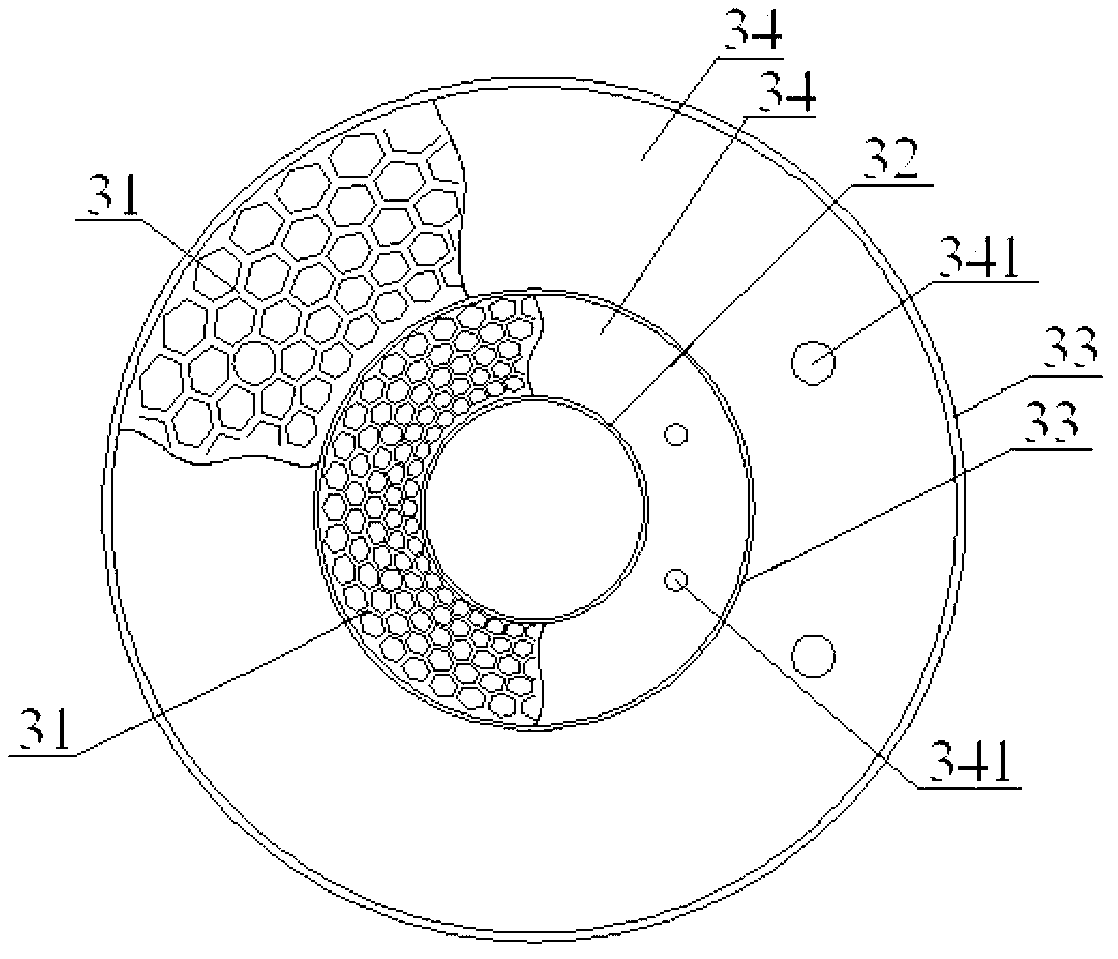

[0026] The flame-retardant explosion-proof valve of the present invention includes a valve cover 1 and a valve seat 2 with a valve disc 21. The top end of the valve cover 1 is connected to one end of the spring 11, and the other end of the spring 11 is tightly pressed. On the valve flap 21 of the valve seat 2, the sealing ring 22 is used to seal between the valve flap 21 and the valve seat 2, and the valve seat 2 and the valve cover 1 are installed Flame retardant device 3, said flame retardant device 3 includes a sheet-shaped flame retardant sheet 31, an inner flame retardant ring 32 and several outer flame retardant rings 33, said flame retardant sheet 31 is installed on said inner flame retardant Ring 32 and the mounting hole 341 in the annular cavity 34 formed by the outer flame-retardant ring 33; several bosses 312 are distributed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com