Patents

Literature

44results about How to "Full contact heat transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

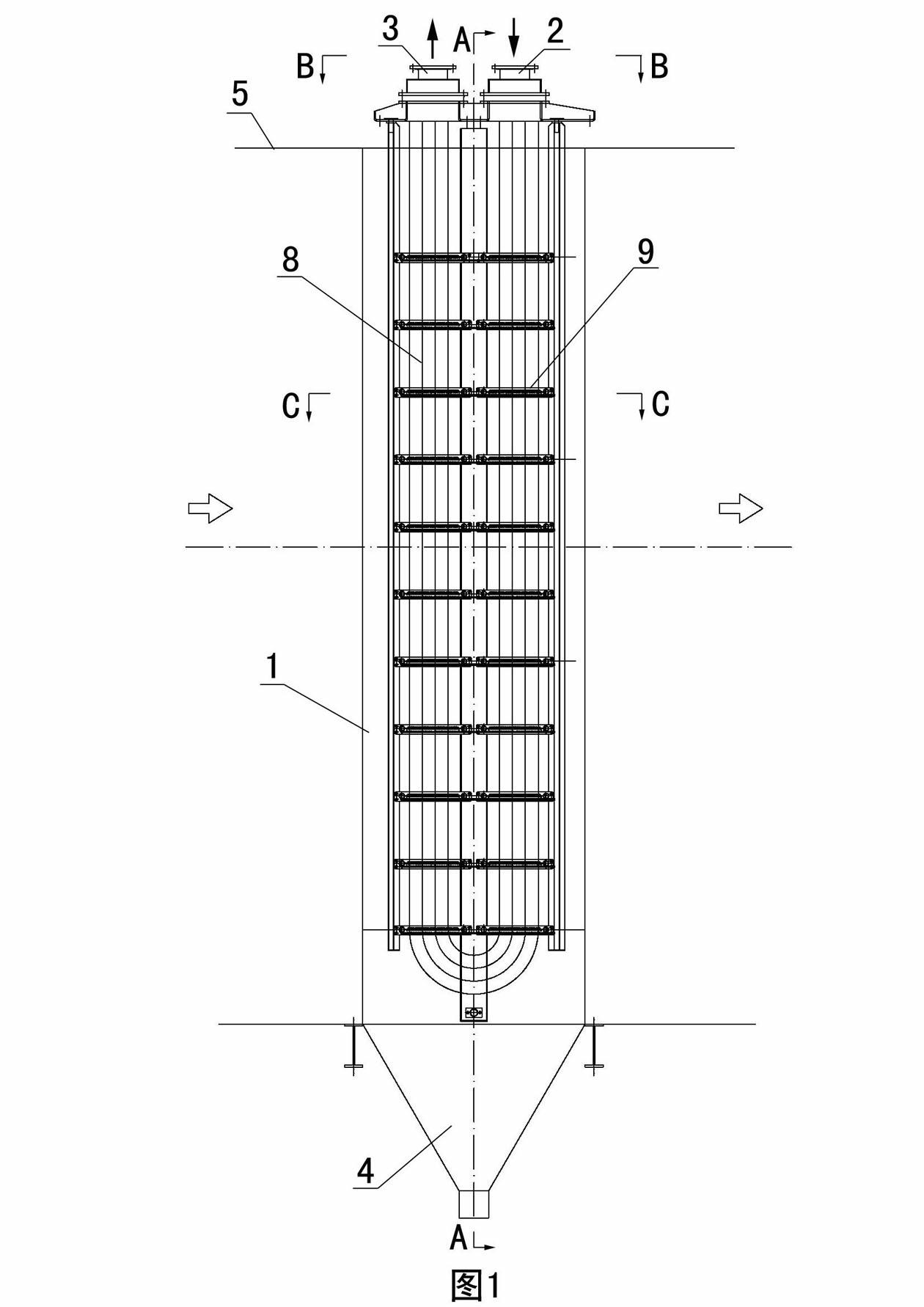

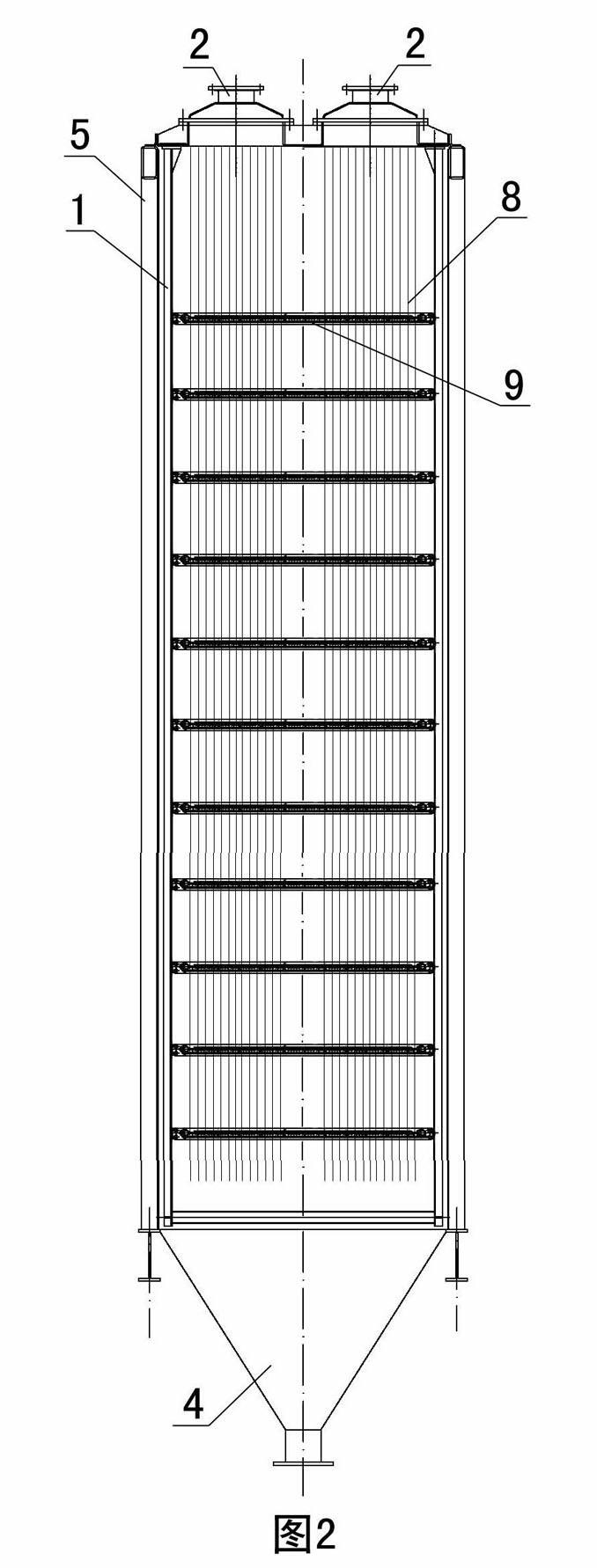

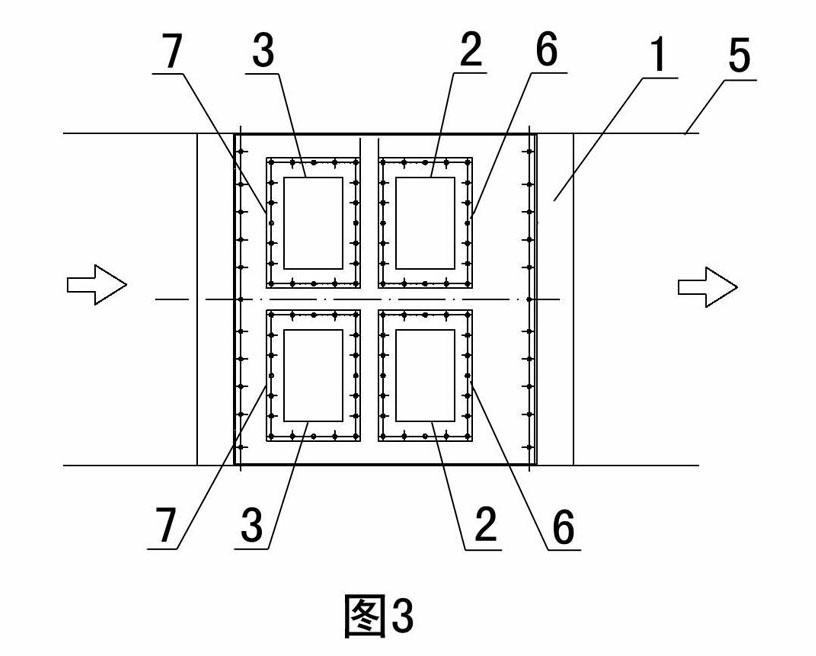

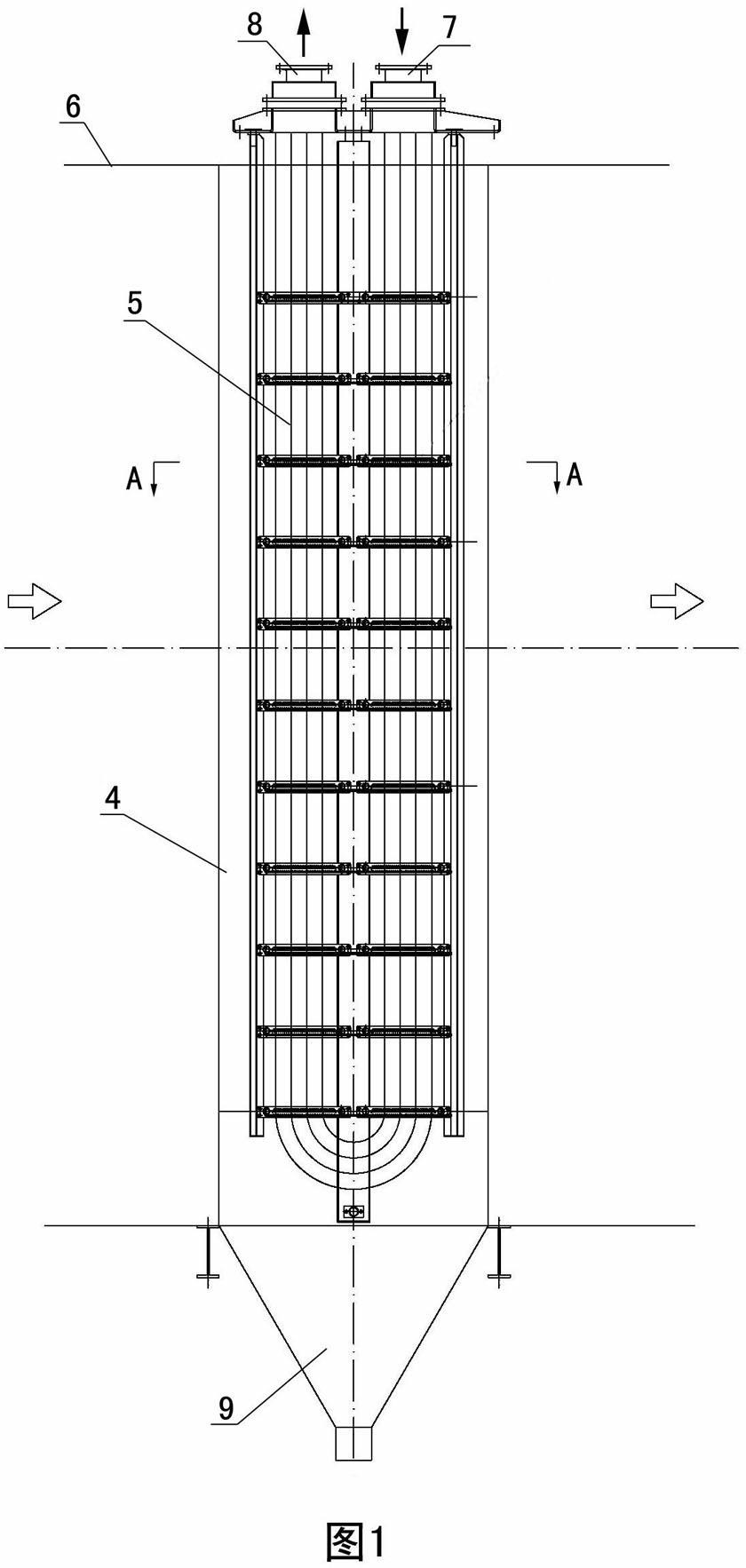

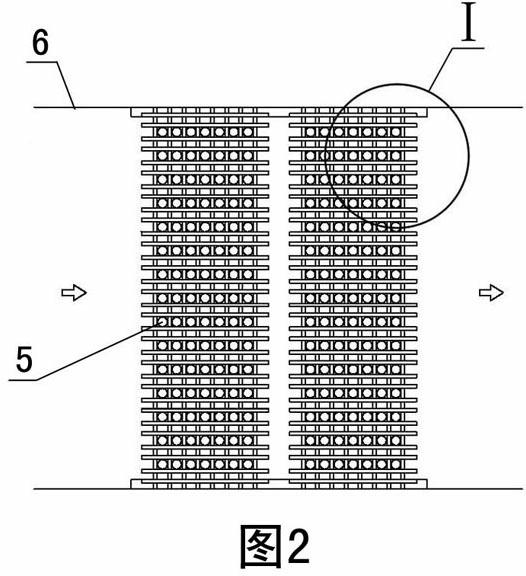

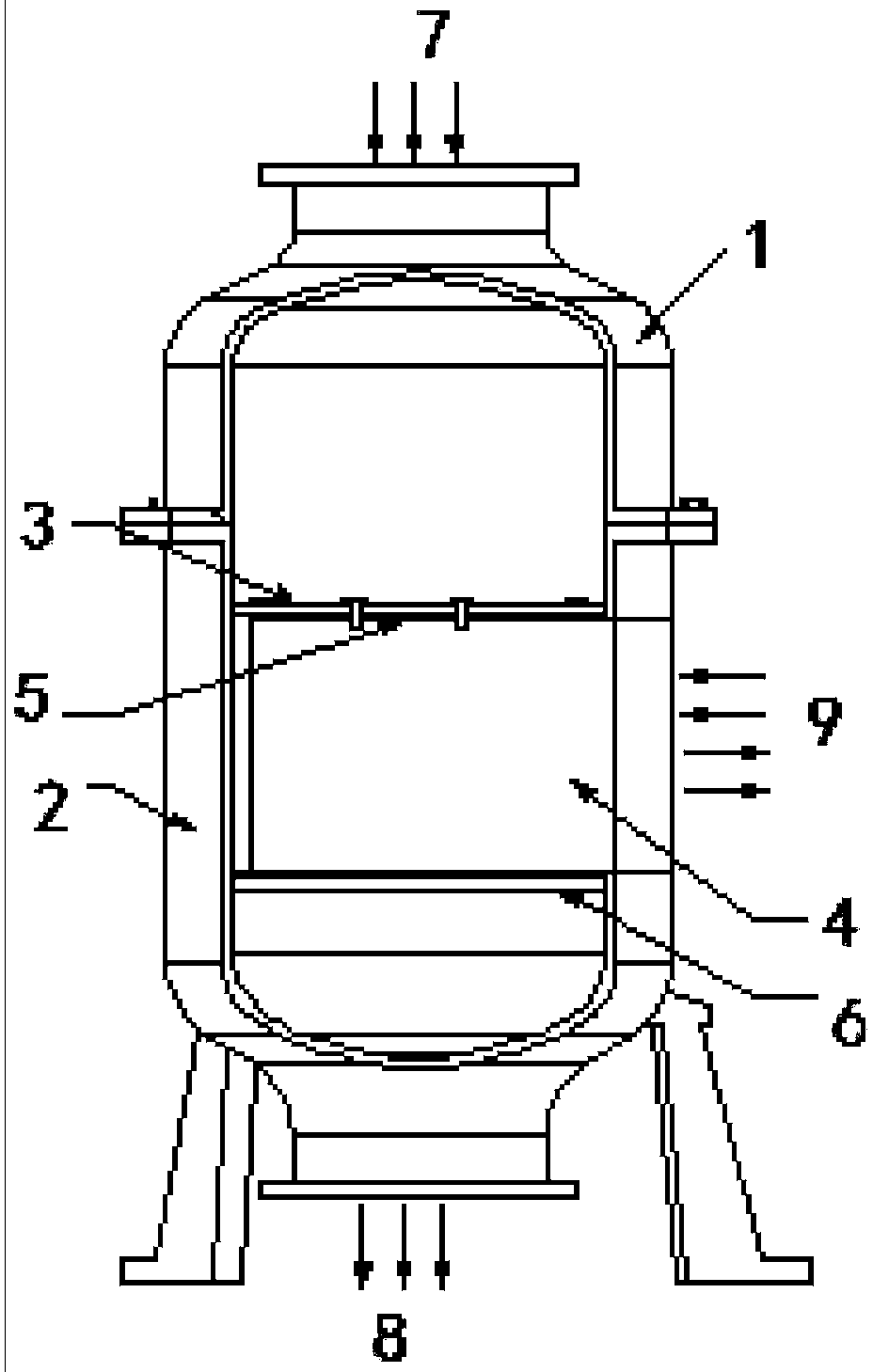

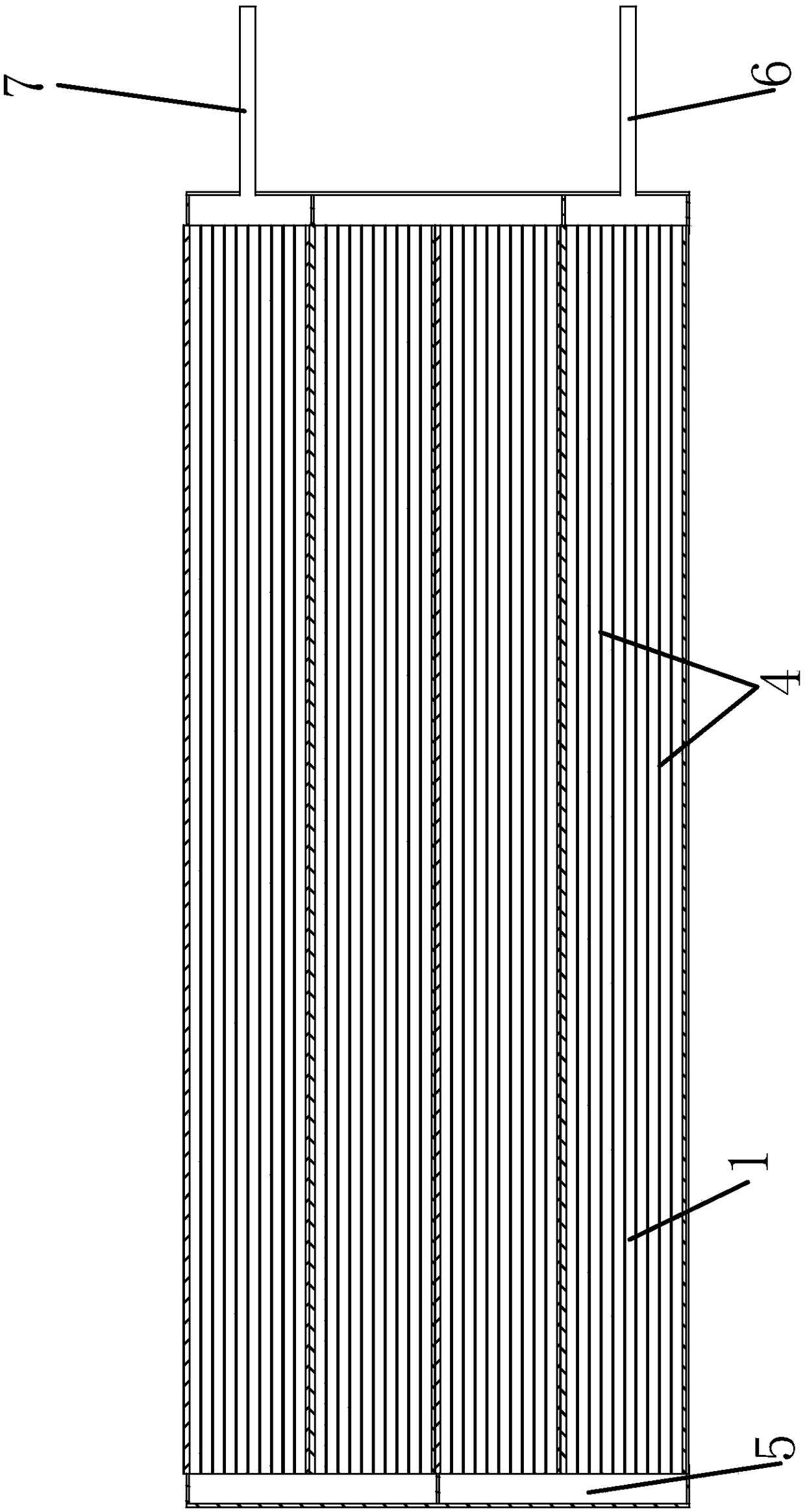

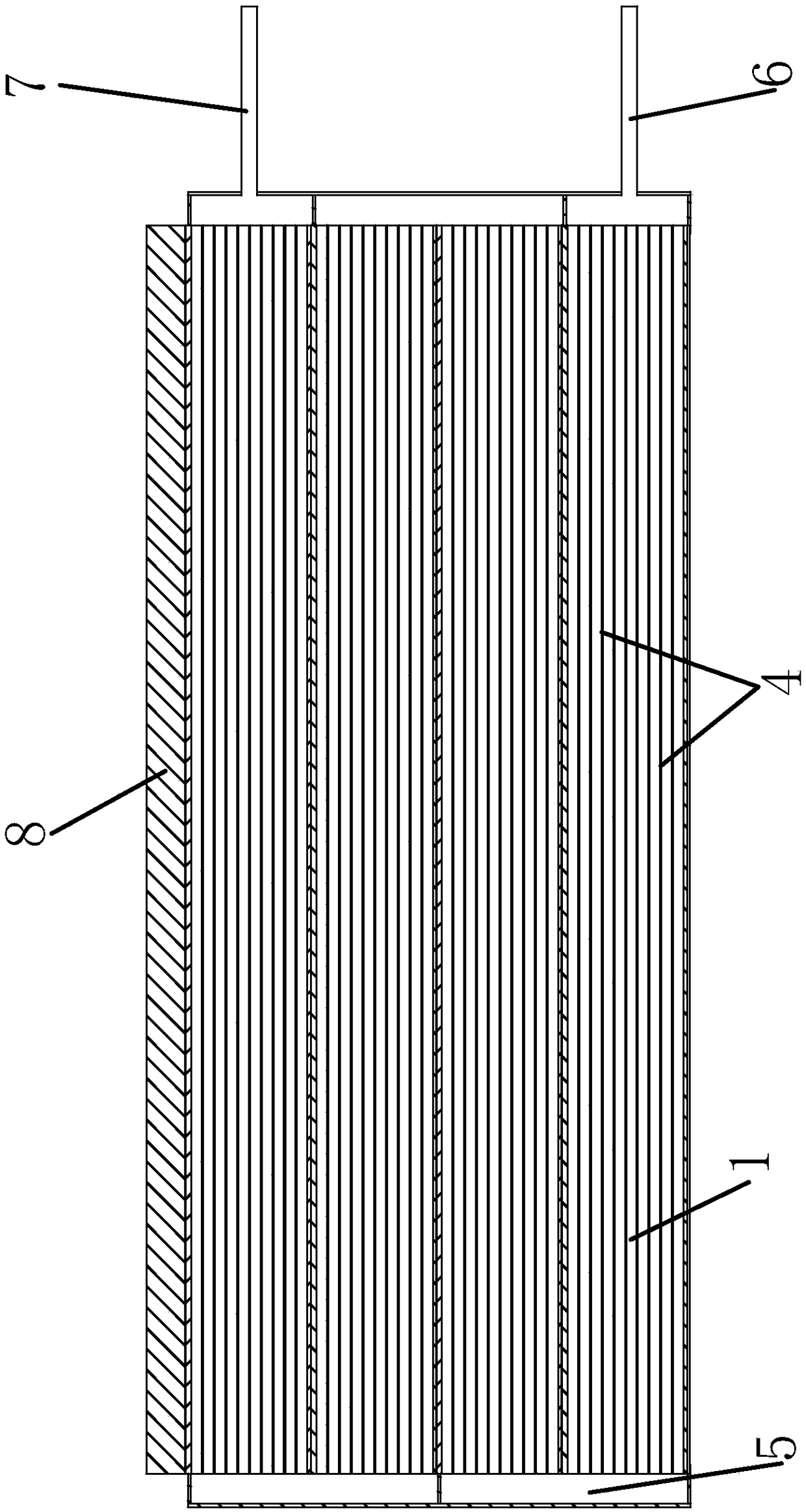

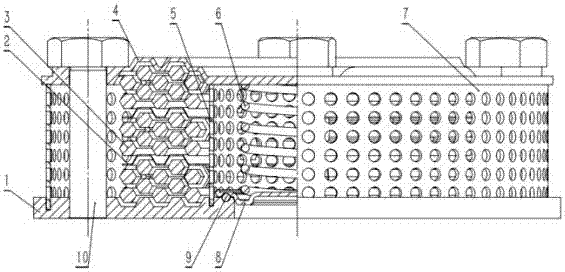

Module type flue gas heat exchanger with fluorine plastic pipes

ActiveCN102607299ALow temperature corrosion resistanceStrong antifoulingHeat exchanger casingsStationary tubular conduit assembliesFlue gasEngineering

A module type flue gas heat exchanger with fluorine plastic pipes comprises a heat exchanger casing and a heat exchange pipe, wherein the upper end of the heat exchanger casing is provided with water inlets and water outlets, and the lower end of the heat exchanger casing is provided with a drain outlet. A water inlet end plate is detachably connected to the position of the water inlets and provided with water inlet holes, and a water outlet end plate is detachably connected to the position of the water outlets and provided with water outlet holes. The heat exchange pipes are U-shaped fluorine plastic heat exchange pipe bundles, water inlet ends of the fluorine plastic pipes in the fluorine plastic heat exchange pipe bundles are communicated with the water inlet holes, water outlet ends of the fluorine plastic pipes in the fluorine plastic heat exchange pipe bundles are communicated with the water outlet holes, and positioning nets are parallelly distributed in the heat exchanger casing from top to bottom at intervals. Module type design is adopted by the flue gas heat exchanger, equipment utilizing rate of the flue gas heat exchanger is greatly improved, the positioning nets are used by the flue gas heat exchanger at a fixed interval so as to fix the fluorine plastic pipes in the fluorine plastic heat exchange pipe bundles, and shaking deformation of the flexible fluorine plastic pipes caused by flowing impact of flue gas can be avoided.

Owner:北京新世翼节能环保科技股份有限公司

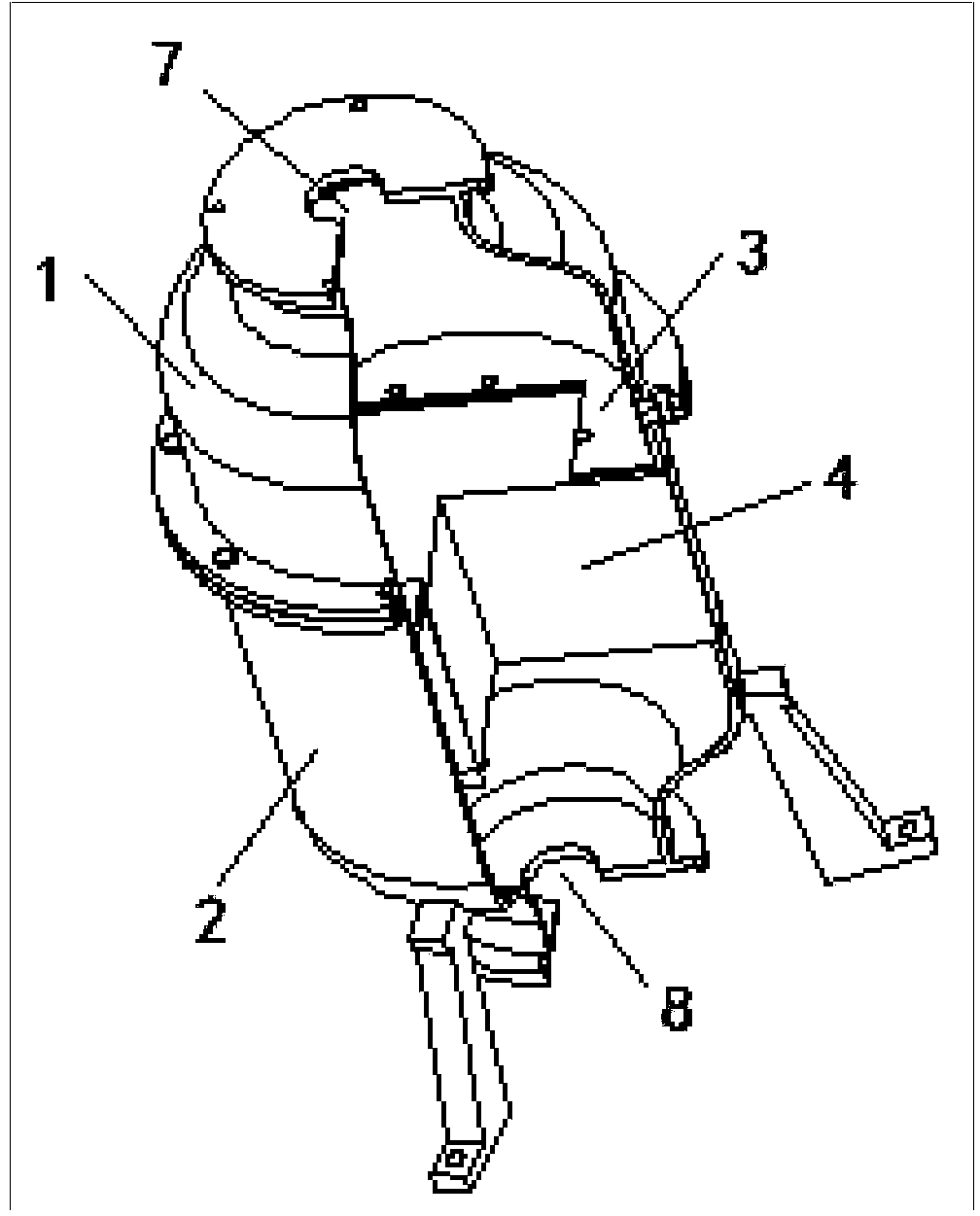

Double air inlet heat-exchange device for condensation type gas water heater

ActiveCN102589128ASmooth contact heat transferFull contact heat transferEnergy efficient heating/coolingAir heatersFlue gasFuel gas

The invention discloses a double air inlet heat-exchange device for a condensation type gas water heater, which comprises a casing, a condensed water collecting box, a condensation heat exchanger and a smoke collecting cover, wherein the casing is of a two-end through structure. A side wall of the condensed water collecting box is provided with a flue gas inlet, the bottom of the condensed water collecting box is provided with a condensed water outlet pipe, a condensed water baffle preventing the condensed water from flowing out of the flue gas inlet is arranged right above the inner side of the flue gas inlet, the smoke collecting cover is provided with a flue gas outlet, the condensed water collecting box is arranged in the casing, the condensation heat exchanger is arranged in the condensed water collecting box, the smoke collecting cover is buckled on the condensed water collecting box, and the condensation heat exchanger is sealed in the smoke collecting cover. The double air inlet heat-exchange device solves the problem that a heat exchanger of an existing condensation type gas water heater is low in heat exchange efficiency, the heat exchanger is corroded due to overflow of the condensed water, the content of CO in the flue gas is too high due to airflow smoothness failure, and the like. The double air inlet heat-exchange device has the advantages that the heat exchange efficiency is high, the air flow is smooth, contents of CO and NOX in the discharged flue gas are low, the overflow of the condensed water is avoided, and the double air inlet heat-exchange device is easy to manufacture.

Owner:HAIER GRP CORP +2

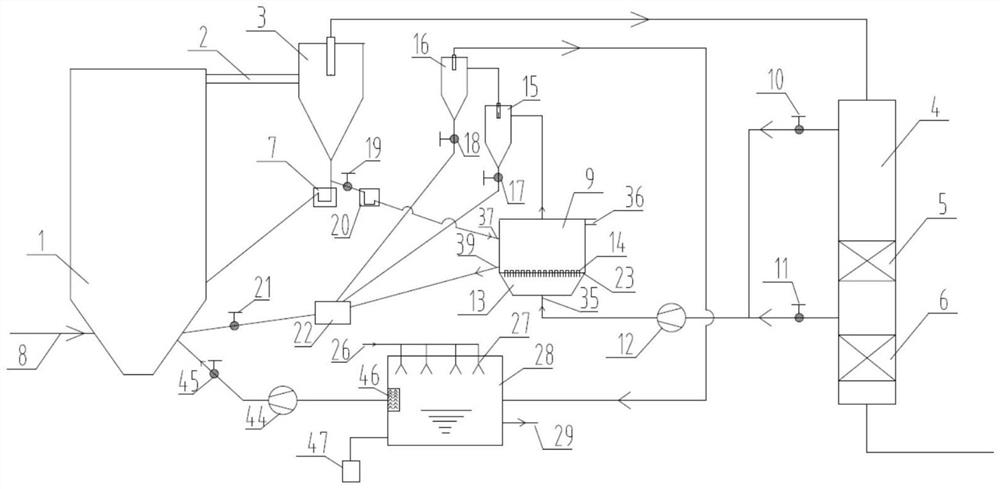

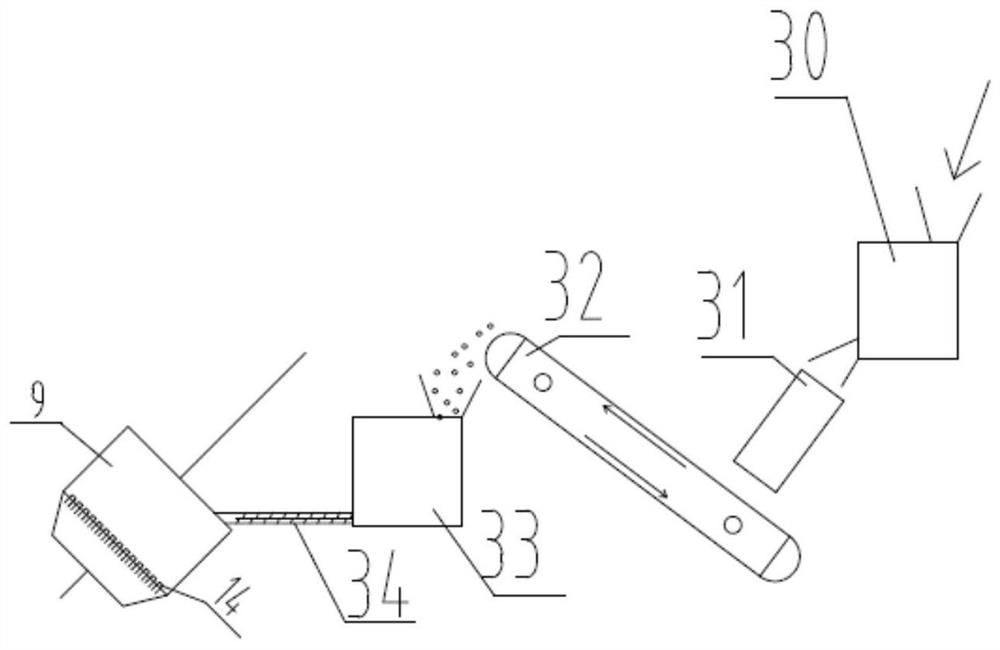

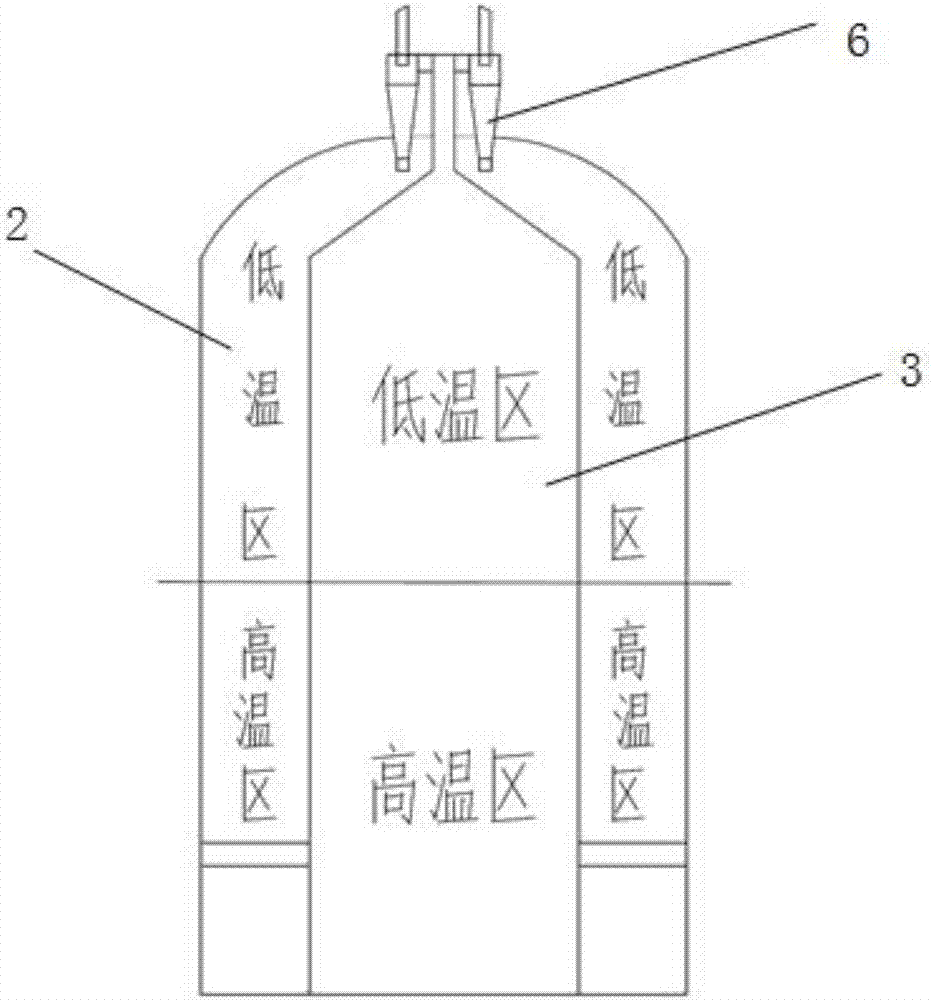

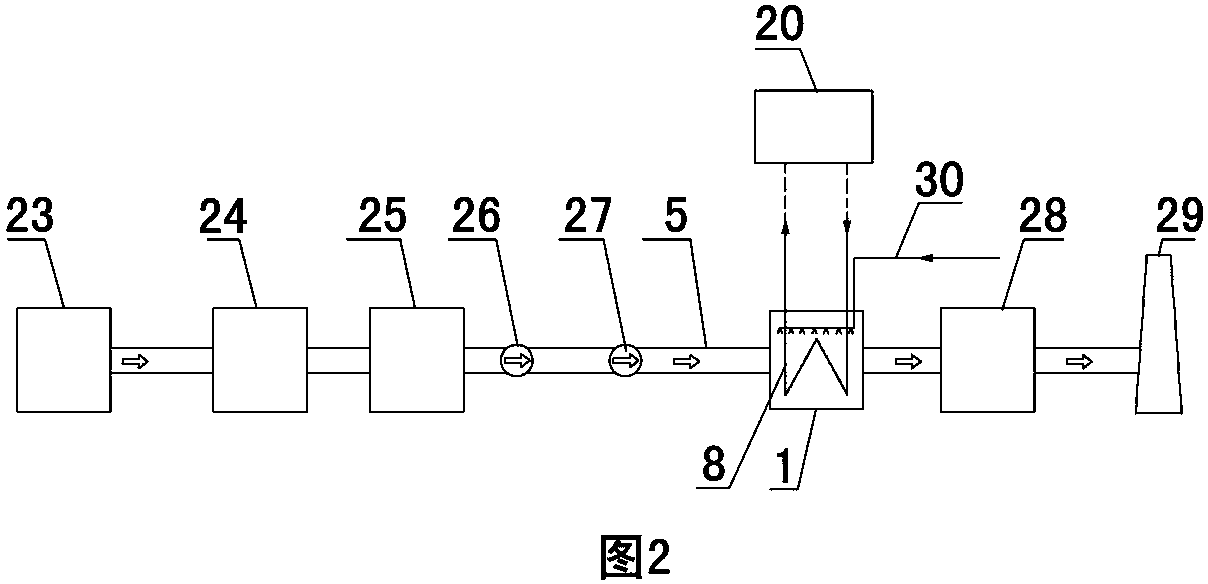

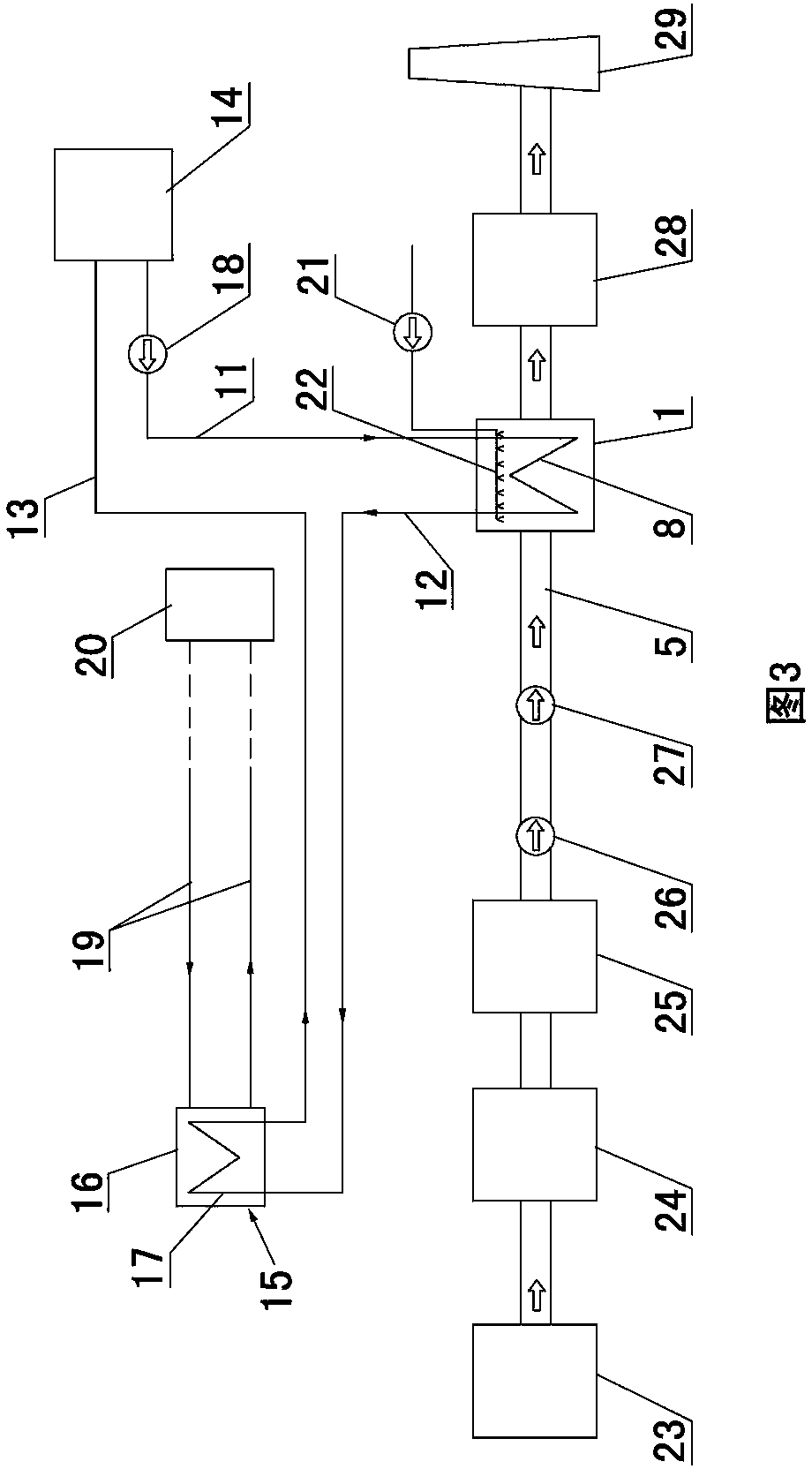

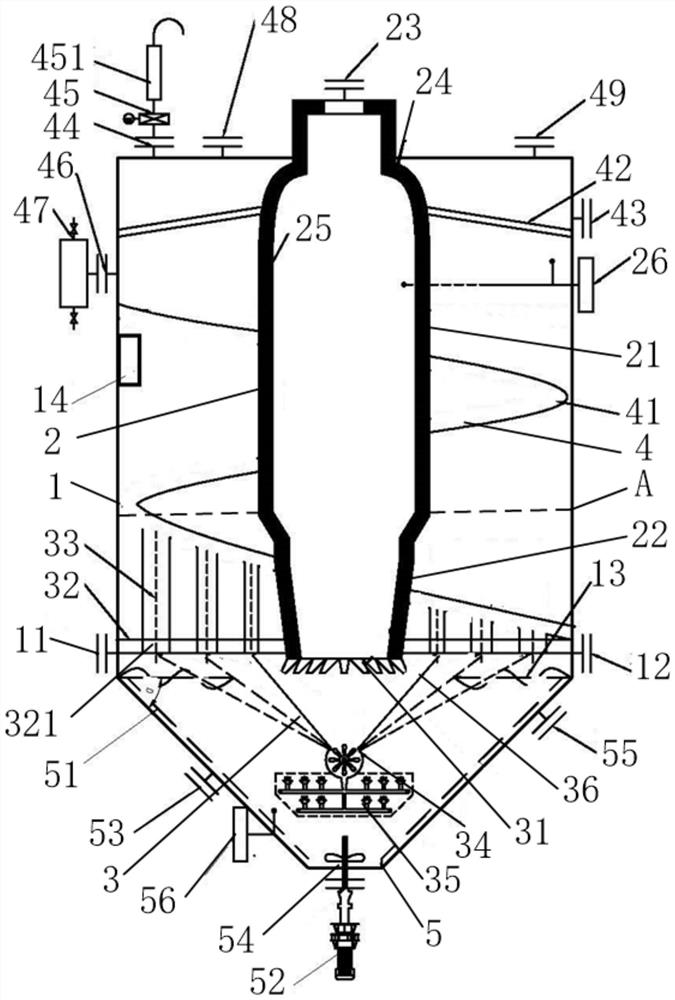

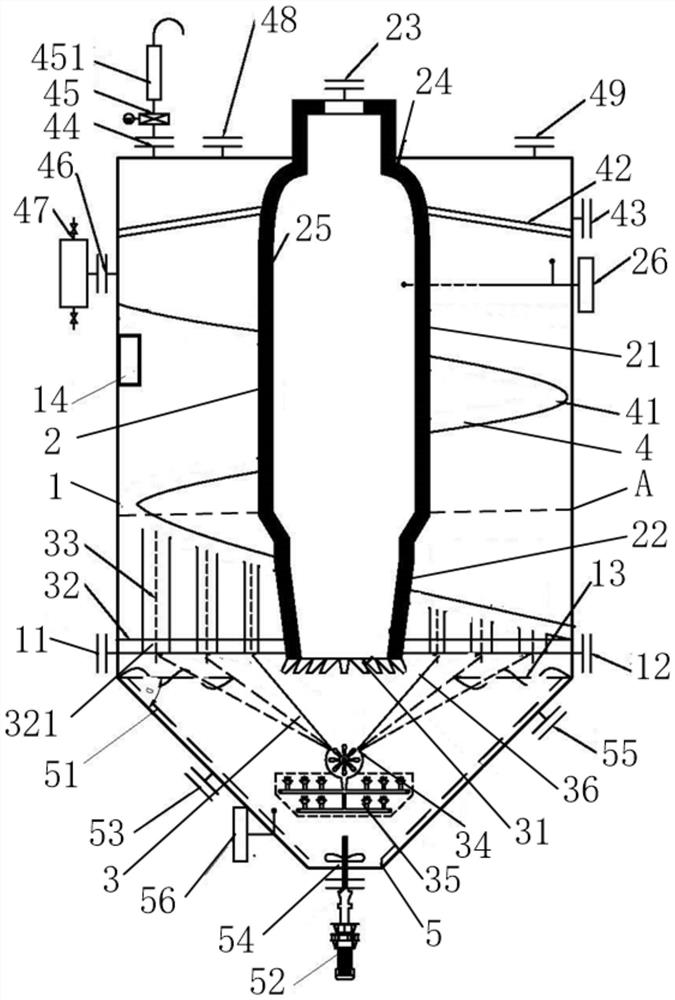

Waste fan blade pyrolysis recovery system and working method thereof

ActiveCN113046107AIndependent and flexible structureHarmlessProductsReagentsFan bladeCirculating fluidized bed boiler

The invention discloses a waste fan blade pyrolysis recovery system and a working method thereof, and belongs to the technical field of resource recovery. The waste fan blade pyrolysis recovery system comprises a crushing system, a circulating fluidized bed boiler system, a pyrolysis reactor, a material collecting and conveying device, a pyrolysis gas-solid separation system and a cracking oil separation system. According to the invention, composite materials in waste blades can be effectively cracked, cracking oil generated by cracking can be recovering, cracking gas is pumped to a hearth to be effectively incinerated, heat value contained in the cracking gas is effectively utilized, pollutants generated in the combustion process can be discharged in a standard reaching mode by means of an environment-friendly device arranged in an original boiler system, and a pyrolysis reaction in a pyrolysis reactor under an anoxic atmosphere effectively avoids the potential problems of dioxin generation and emission, and the like caused by direct incineration of the waste leaves, so that harmless and resourceful treatment of the waste leaves is completely achieved; and before the comprehensive recycling technology of the blade material is mature and utilized on a large scale, the influence of the waste blade on the environment and the like can be effectively solved, and good environmental protection benefits and economic benefits are generated.

Owner:HUANENG CLEAN ENERGY RES INST

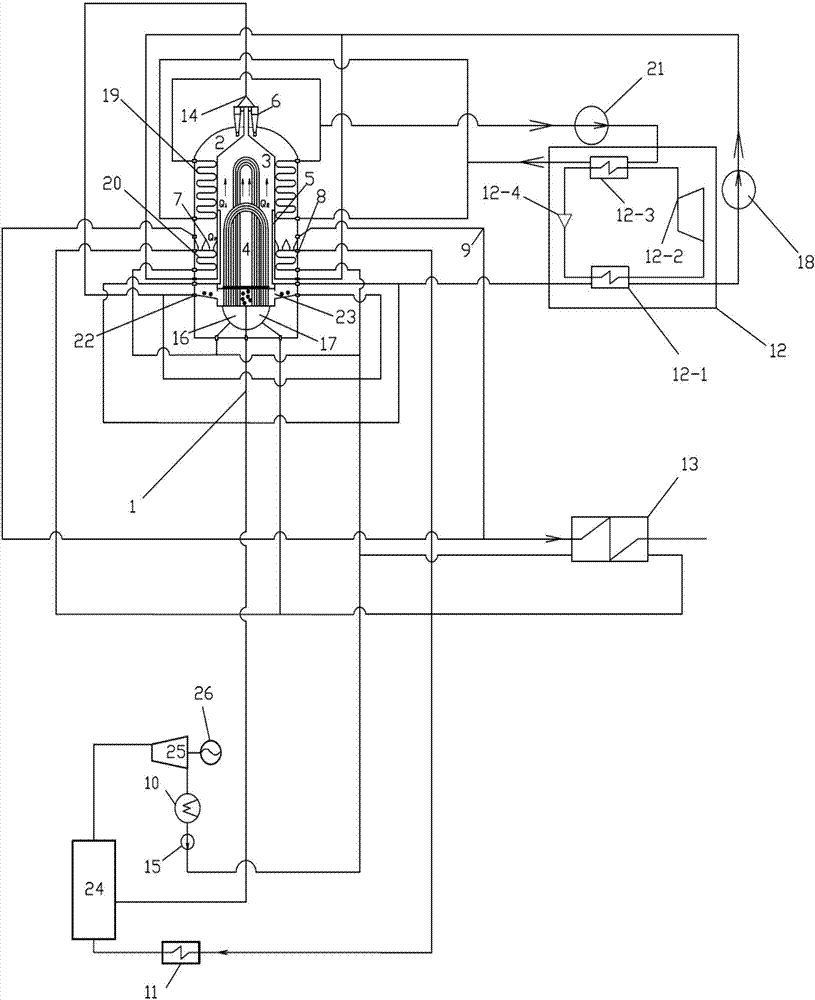

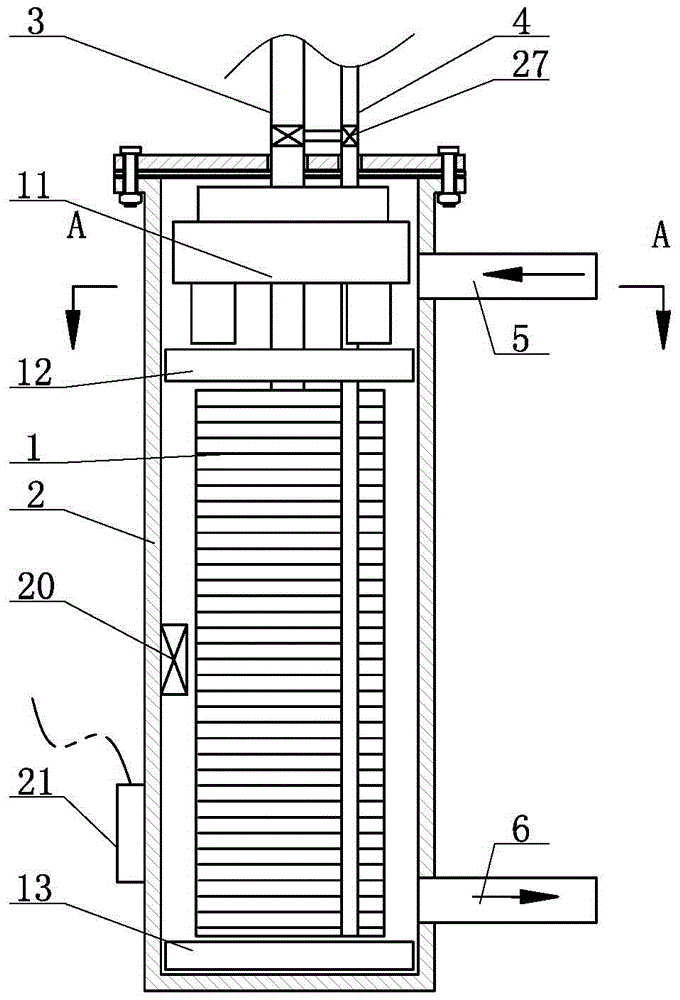

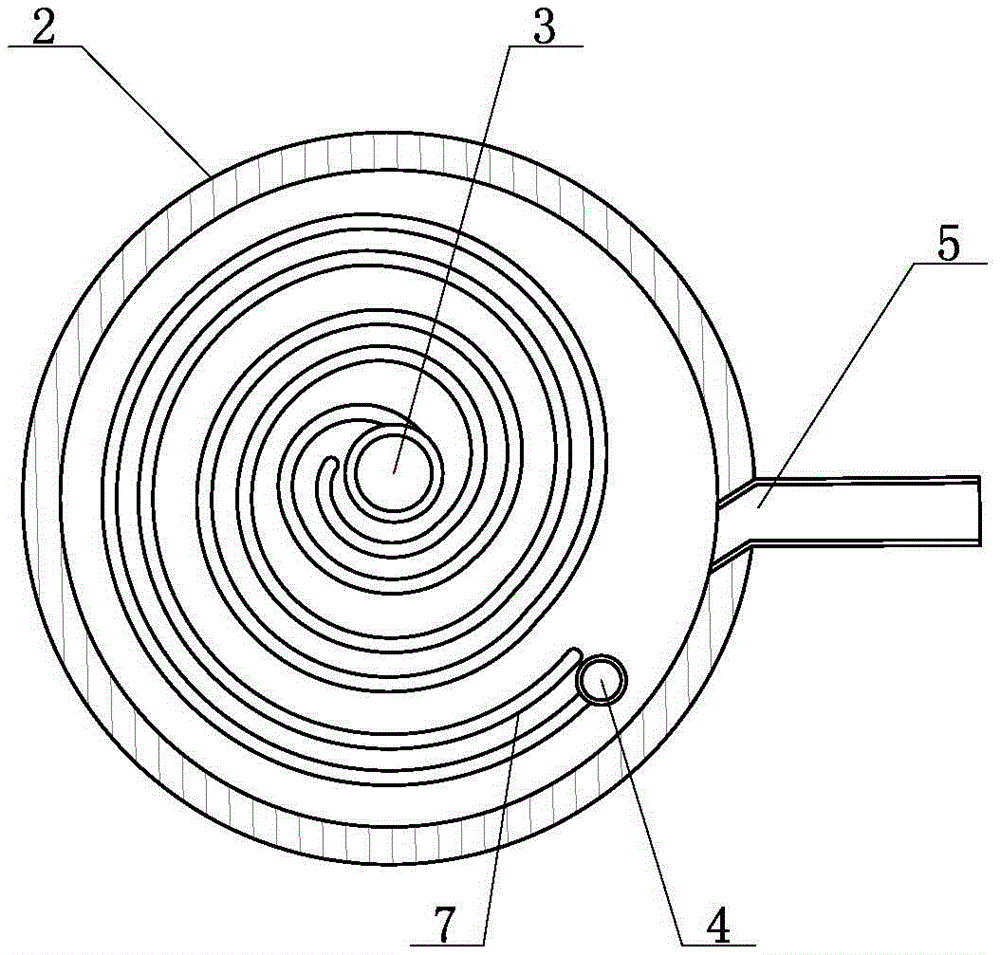

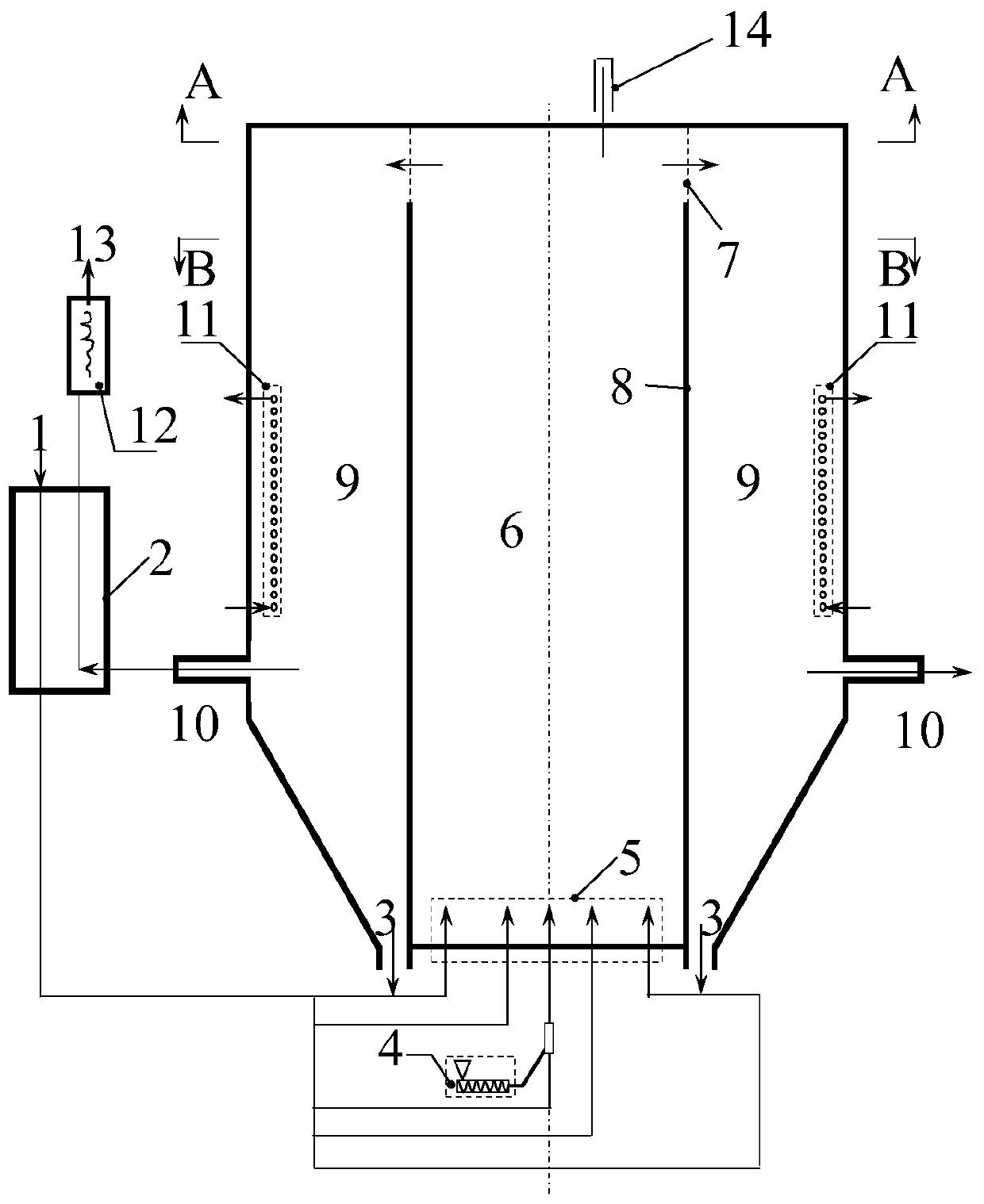

Integrated particle fluidized carbon dioxide capture method and device for power plant

ActiveCN107138024AEasy to transformEasy to installGas treatmentDispersed particle separationFlue gasDesorption

The invention provides an integrated particle fluidized carbon dioxide capture method and device for a power plant. The method comprises the following steps: enabling flue gas to pass through an adsorption tower of the integrated particle fluidized carbon dioxide capture device from bottom to top, and efficiently absorbing carbon dioxide from porous silicon particles in the tower; enabling the particles to enter a desorption column after absorption completion, performing heated desorption under heating of a heat exchanger, and collecting the obtained carbon dioxide by a carbon dioxide collection pipe; and cooling the desorbed particles in a particle cooling area, and leading out partial treated flue gas, blowing the cooled particles into the desorption column via a particle inlet so as to enter the next cycle. The method has the advantages of being scientific, reasonable, high in applicability, capable of realizing large-scale application, stable and reliable in operation, high-efficiency, energy-saving, low in operation and maintenance cost, and the like.

Owner:NORTHEAST DIANLI UNIVERSITY

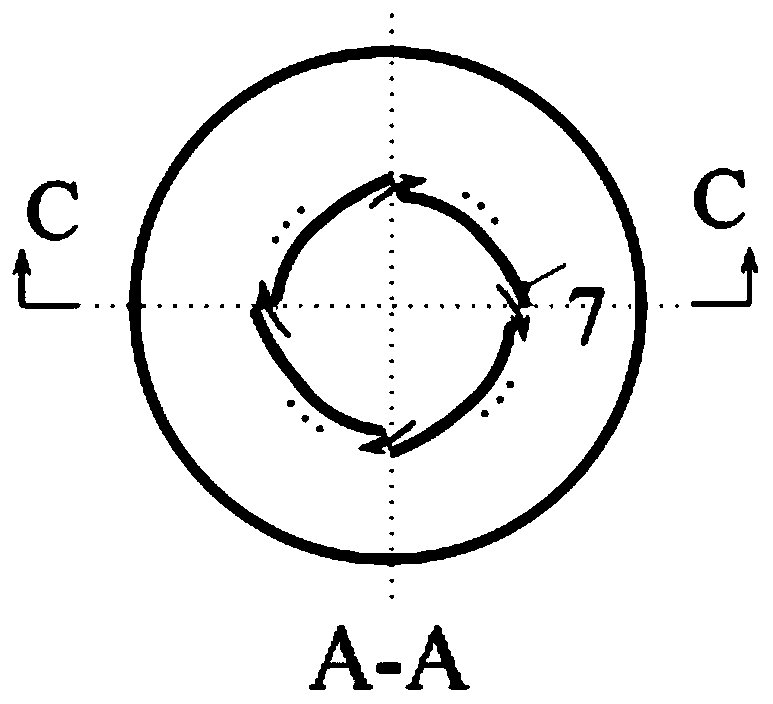

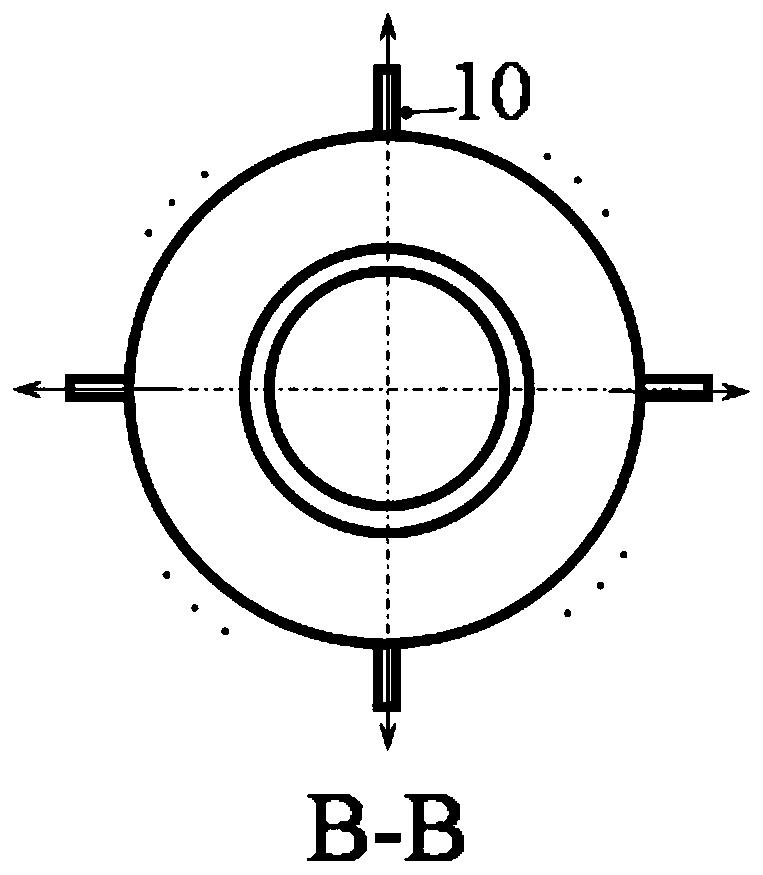

Capillary eddy heat exchanger

PendingCN106091481AFull heat exchangeImprove heat transfer effectSafety devices for heat exchange apparatusEvaporators/condensersWater circulationEngineering

The invention discloses a capillary eddy heat exchanger and belongs to the field of ground source heat pump devices. The capillary eddy heat exchanger is characterized by comprising a main case, a cooling-medium circulation line is arranged in the main case, a water inlet and a water outlet are respectively arranged in side walls of two ends of the main case, and the water inlet is located above the water outlet; the cooling-medium circulation line comprises an inlet pipe and an outlet pipe, a plurality of branch pipes with two ends communicated with the inlet pipe and the outlet pipe are arranged in parallel, and the branch pipes are spirally wound the inlet pipe or the outlet pipe from the periphery; the water inflowing direction of the water inlet forms a 0-45-degree included angle with the main case; water-inflowing rotation direction is opposite to the flowing direction of a cooling medium, and water circulation is opposite to circulation flowing direction of the cooling medium, and with over-entering and down-out water flow, more sufficient heat exchange is achieved. Besides, the capillary eddy heat exchanger is provided with a guiding device, a supporting device and a protecting device, hermetic heat exchanging space enclosed by upper and lower separating sealing rubber gaskets and the inner wall of the main case enables the capillary eddy heat exchanger to be more compact in structure, practical, safe and convenient and long in service life.

Owner:山东绿泉空调科技有限公司

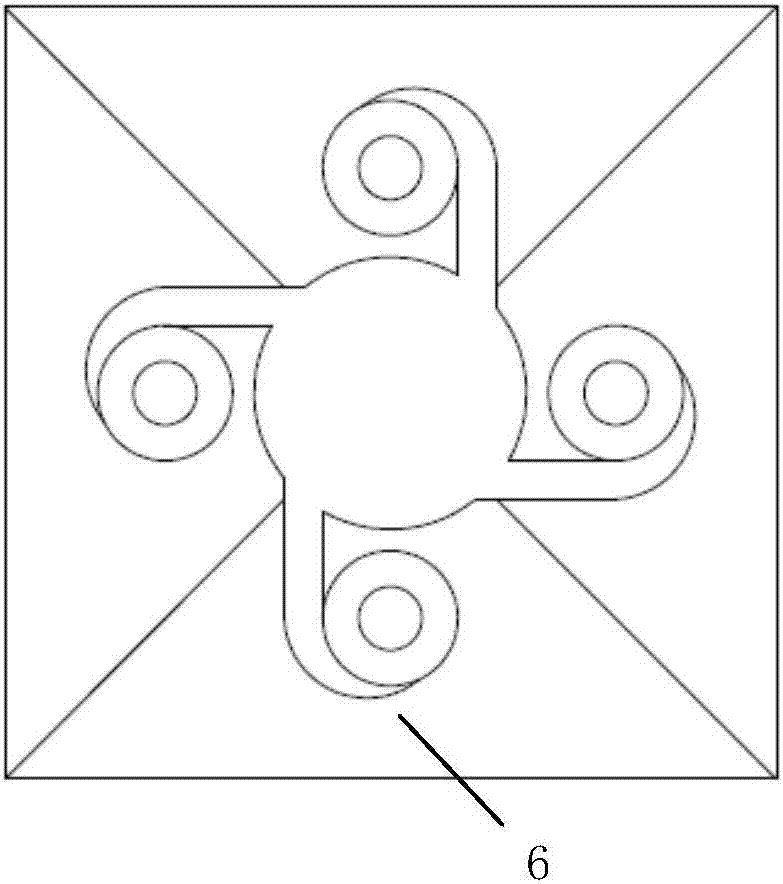

Flameless combustion system for semi-coke refractory fuel

ActiveCN110425520AEfficient use ofImprove utilization efficiencyPulverulent fuel combustion burnersIndirect carbon-dioxide mitigationCombustion systemCombustion chamber

The invention belongs to the field of semi-coke combustion, and particularly discloses a flameless combustion system for semi-coke refractory fuel. The system comprises a combustion chamber, a burner,a powder feeding device and a flue gas treatment device, wherein the combustion chamber is divided into an inner combustion chamber and an outer annular combustion chamber by a partition plate; the lower end of the inner combustion chamber is provided with the burner; the upper end of the partition plate is provided with a tangential flow guiding outlet; the outer wall of the outer annular combustion chamber is provided with a water cooling pipe and a flue gas outlet; a return hopper is arranged at the bottom end of the outer annular combustion chamber; the burner comprises a primary air spray pipe, a flame secondary air spray pipe, a flameless secondary air spray pipe and a material returning spray pipe which are coaxially arranged, and also comprises an ignition assembly extending intothe inner combustion chamber; the powder feeding device is connected with the primary air spray pipe and used for providing fuel for the primary air spray pipe; and the flue gas treatment device comprises a waste heat exchanger and a dust remover which are sequentially connected. According to the system, combustion process and flue gas utilization process are separated, so that high-temperature environment required by the flameless combustion of the inner combustion chamber is ensured; and flue gas heat is effectively utilized.

Owner:HUAZHONG UNIV OF SCI & TECH +2

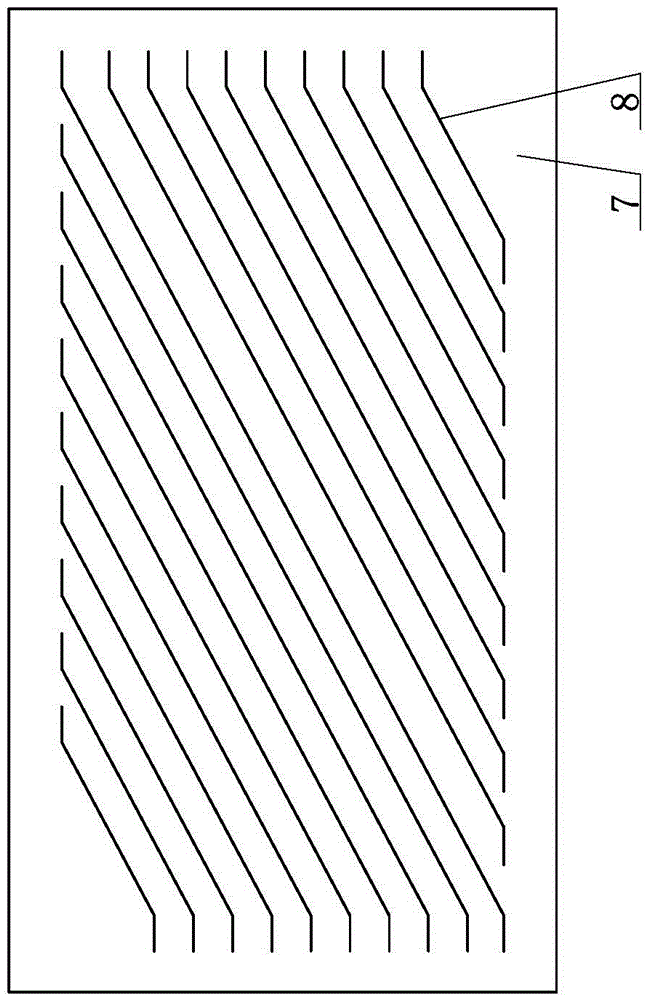

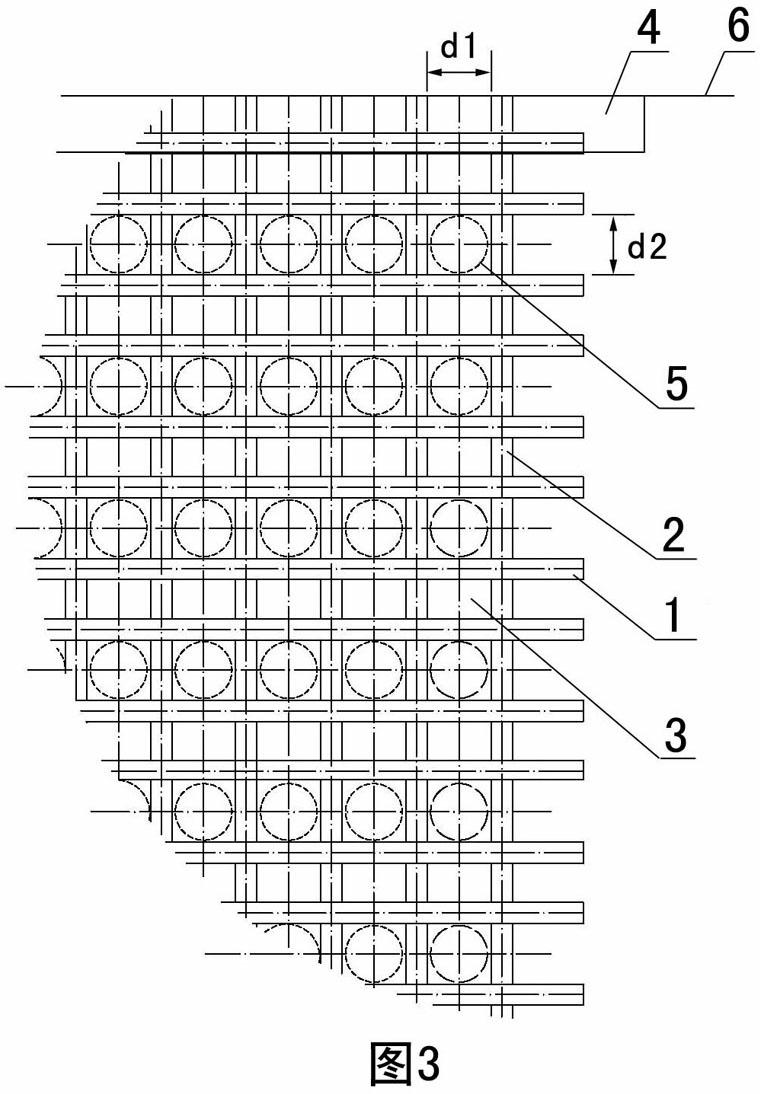

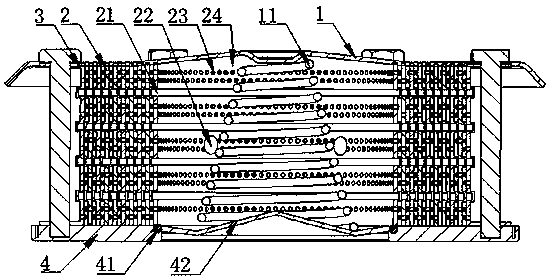

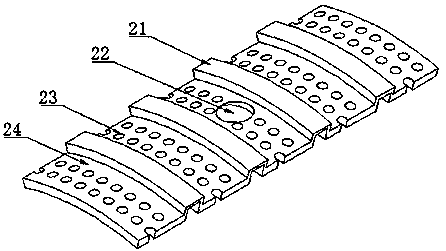

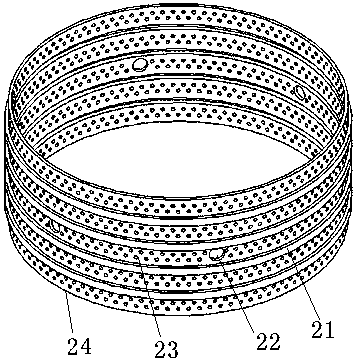

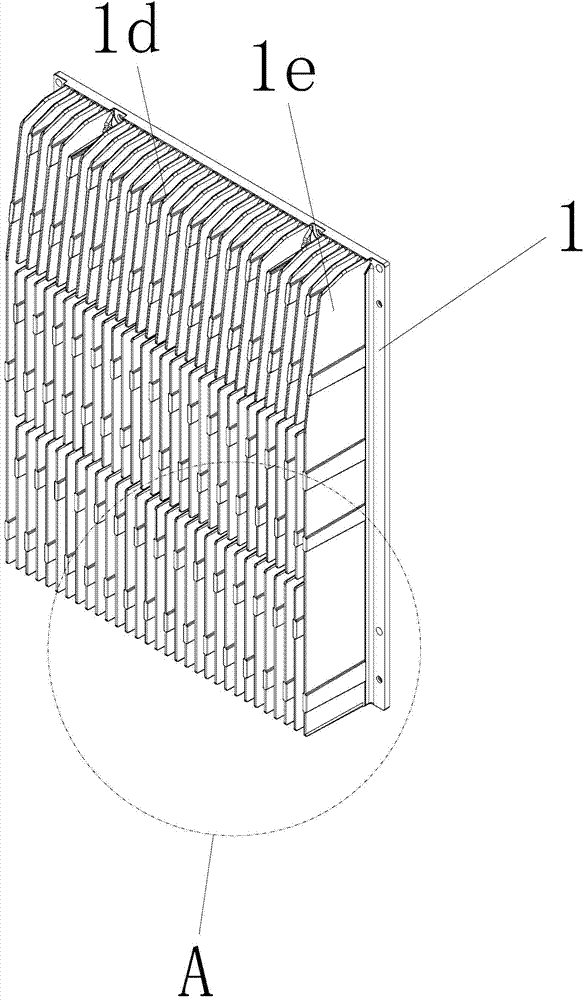

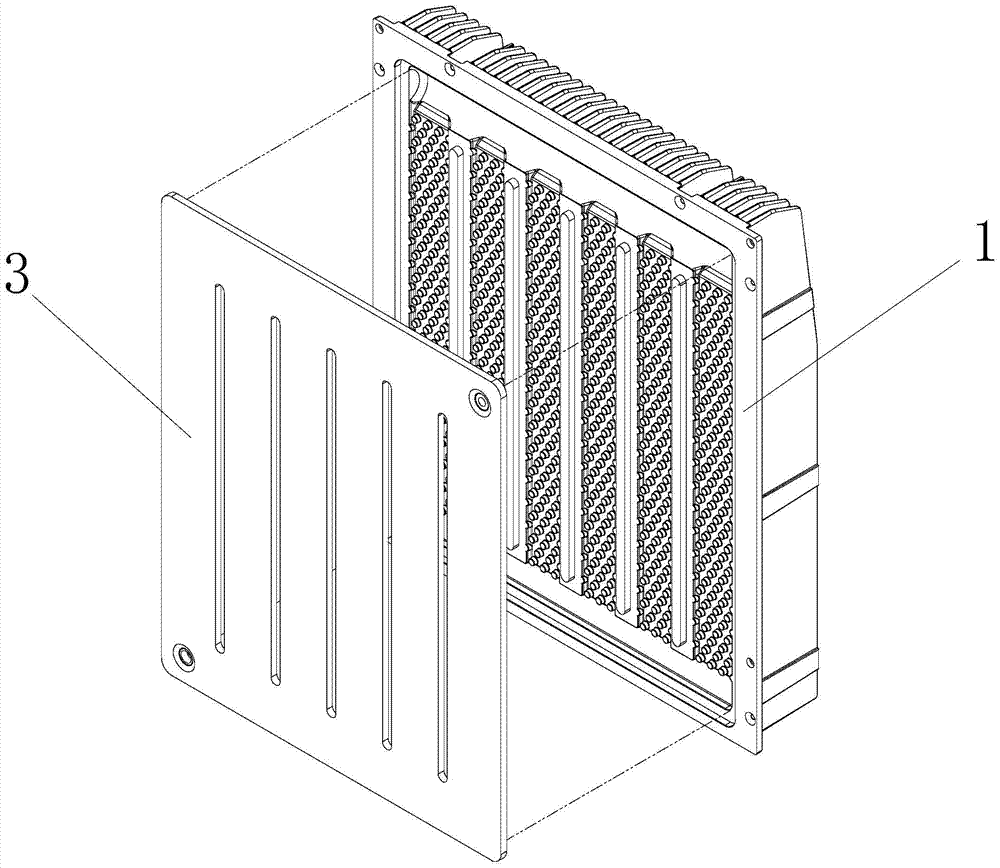

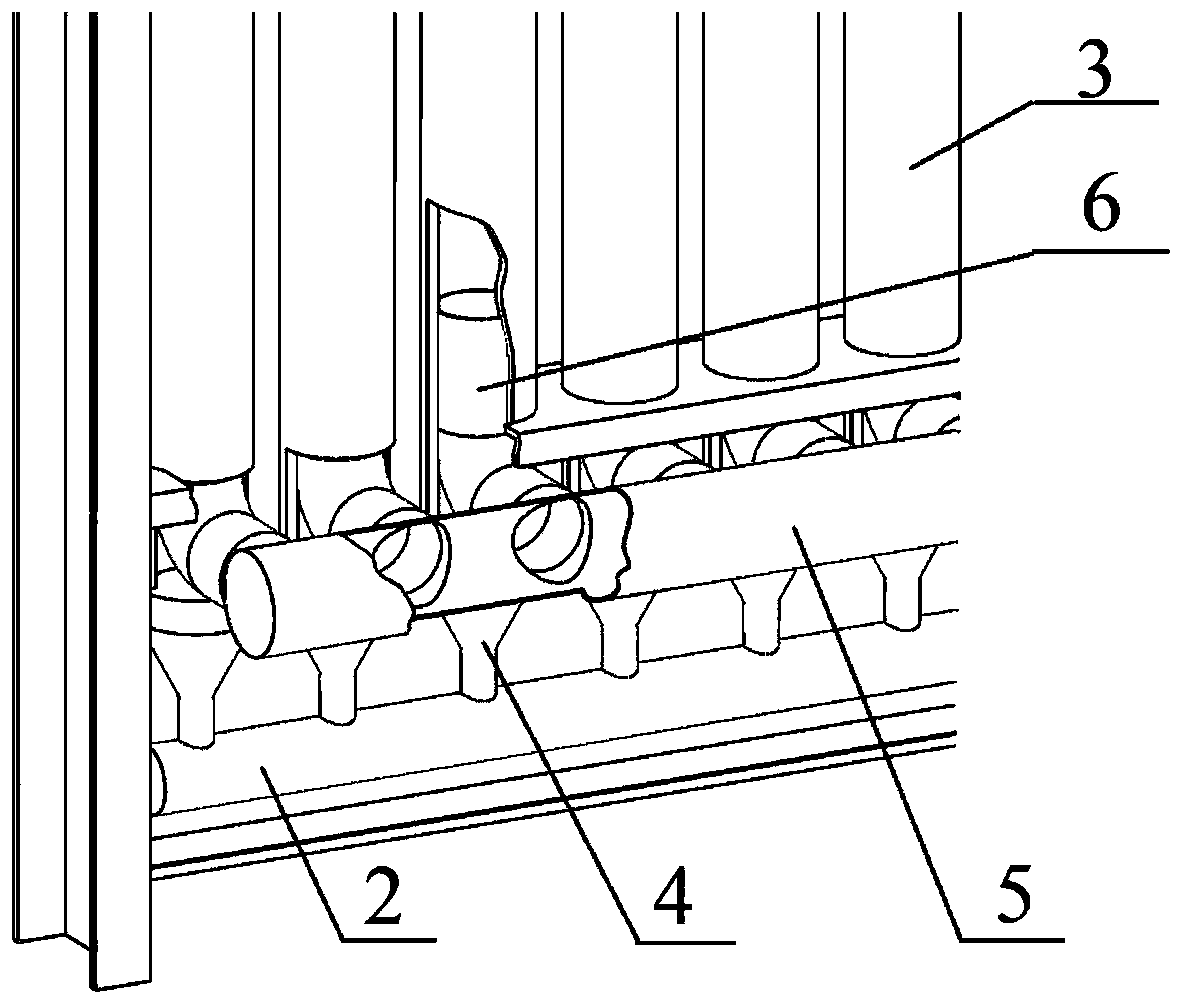

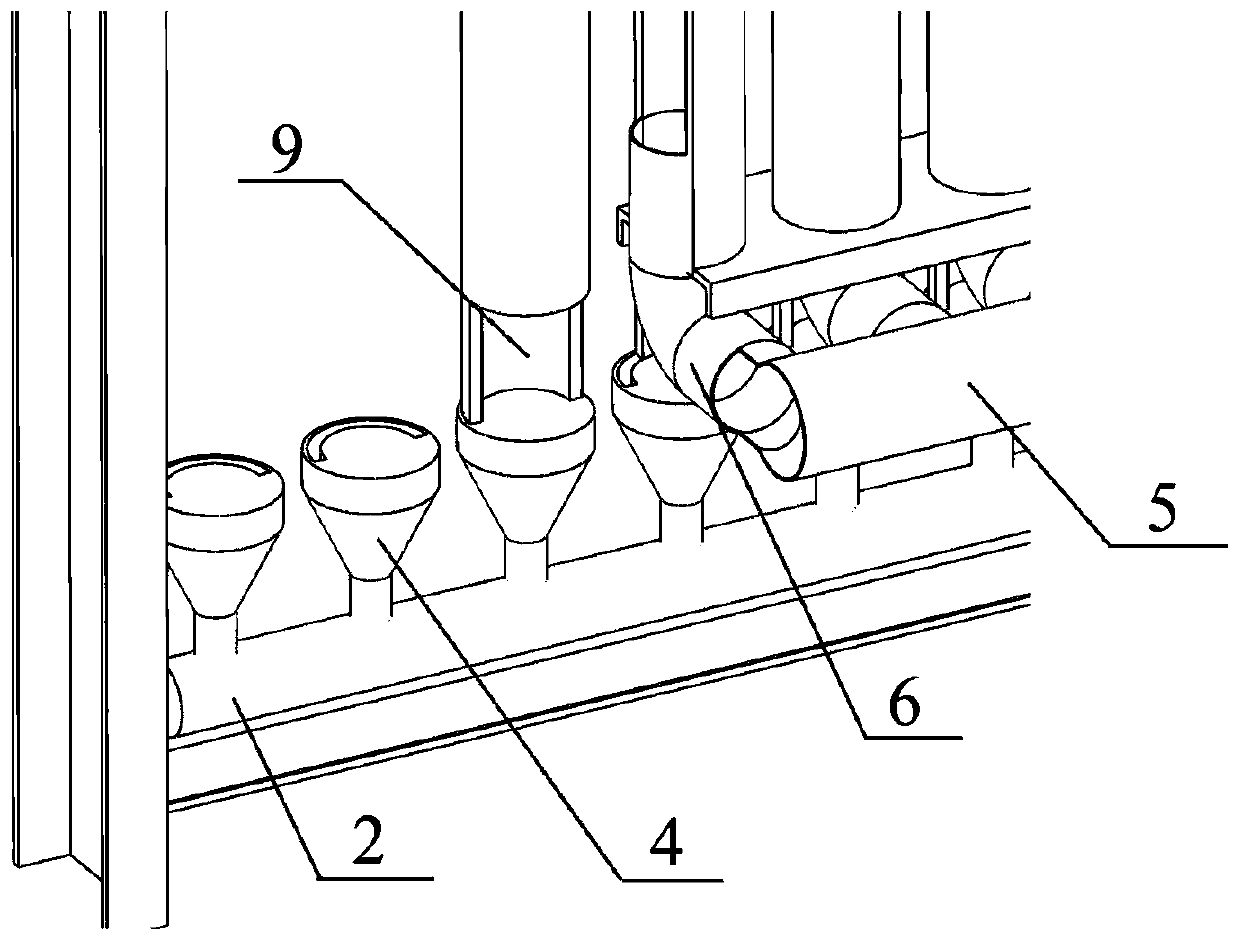

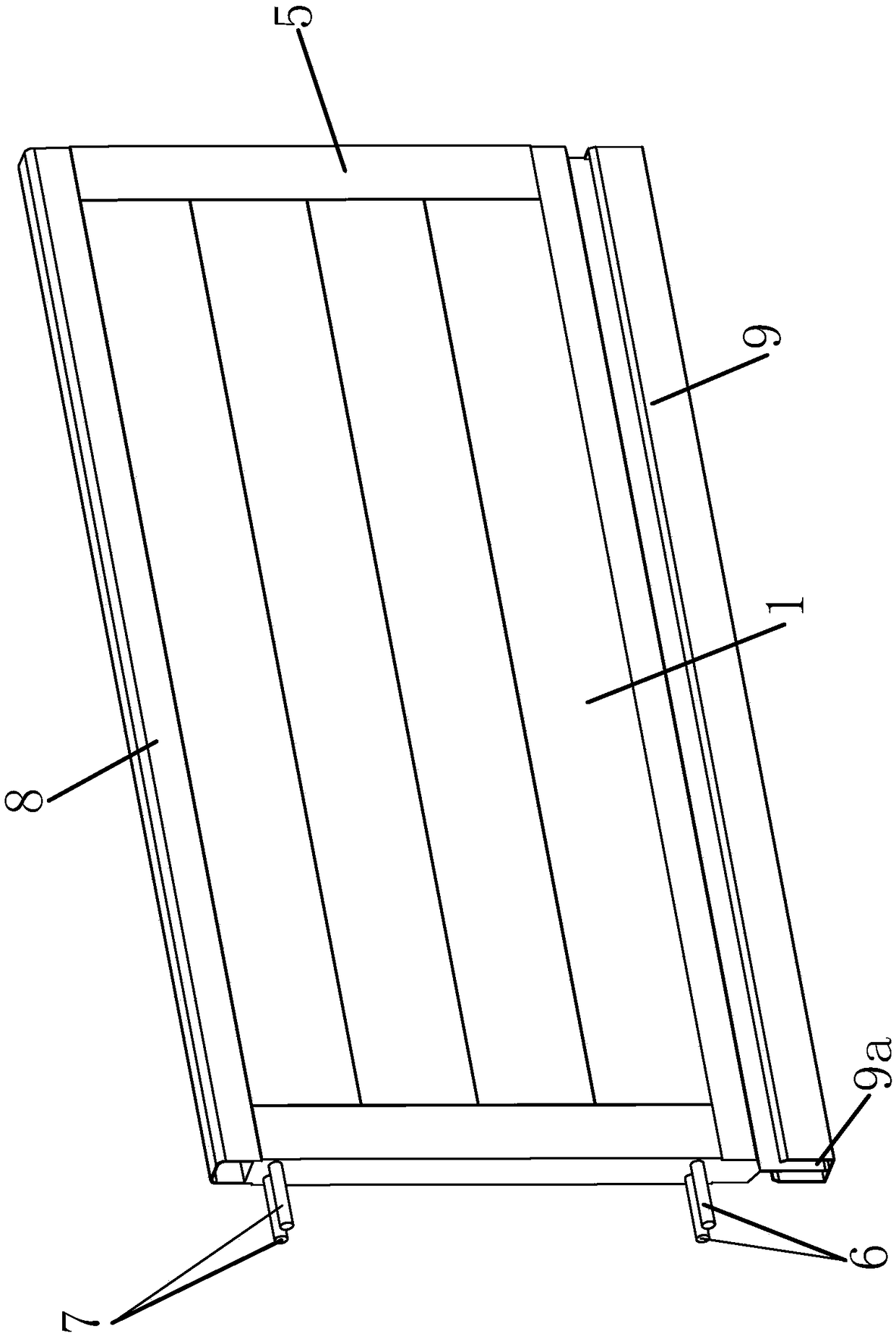

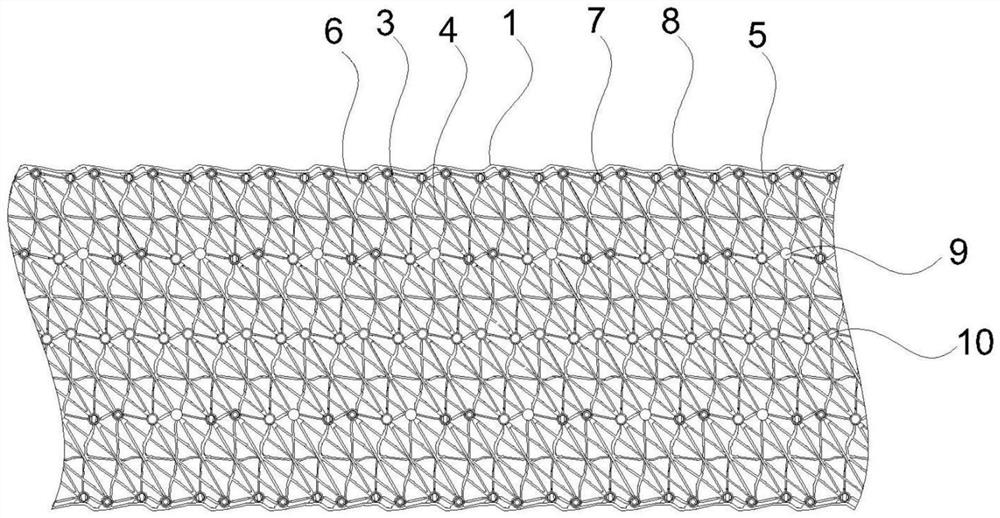

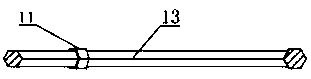

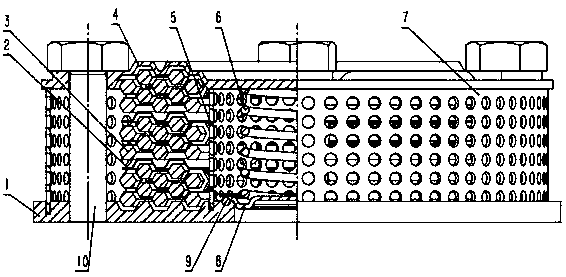

Heat exchange tube bundle positioning net for flue gas heat exchanger with fluorine plastic heat exchange tubes

InactiveCN102607319AAvoid jitter distortionGuaranteed uptimeHeat exchanger casingsFlue gasEngineering

A heat exchange tube bundle positioning net for a flue gas heat exchanger with fluorine plastic heat exchange tubes is formed by interweaving parallelly distributed positioning net weft and parallelly distributed positioning net warp. The positioning net is made of a rigid high-temperature-resistant corrosion-resistant material, the net surface of the positioning net is perpendicular to the axis of the heat exchange tube bundle, the size of each mesh of the positioning net is adapted to the diameter of each fluorine plastic heat exchange tube, and the periphery of the positioning net extends to an inner wall of a flue gas heat exchanger casing. The heat exchange tube bundle positioning net is applied to the flue gas heat exchanger with the fluorine plastic heat exchange tubes, is used for positioning a fluorine plastic heat exchange tube bundle, can avoid shaking deformation of the fluorine plastic heat exchange tube bundle caused by flowing impact of flue gas, enables the fluorine plastic heat exchange tubes in the flue gas heat exchanger with the fluorine plastic heat exchange tubes to maintain intervals, enables the flue gas to circulate smoothly and guarantees full contact and heat exchange between the flue gas and the fluorine plastic heat exchange tubes.

Owner:北京新世翼节能环保科技股份有限公司

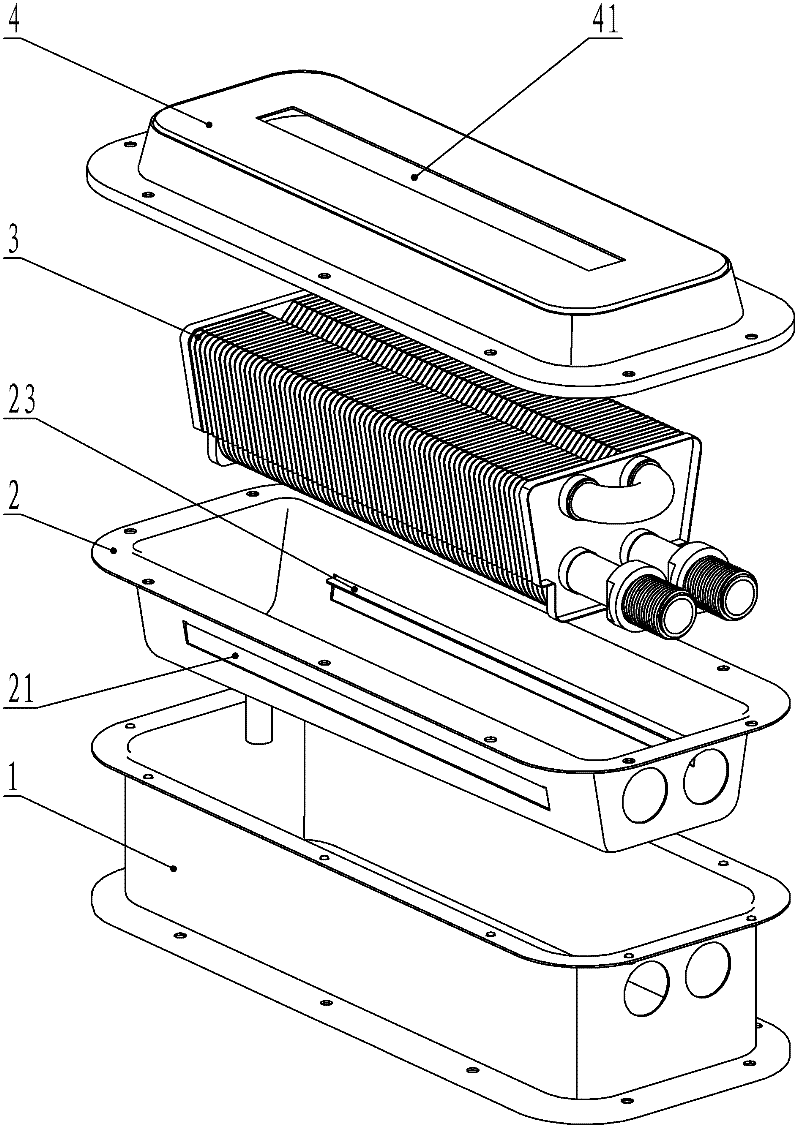

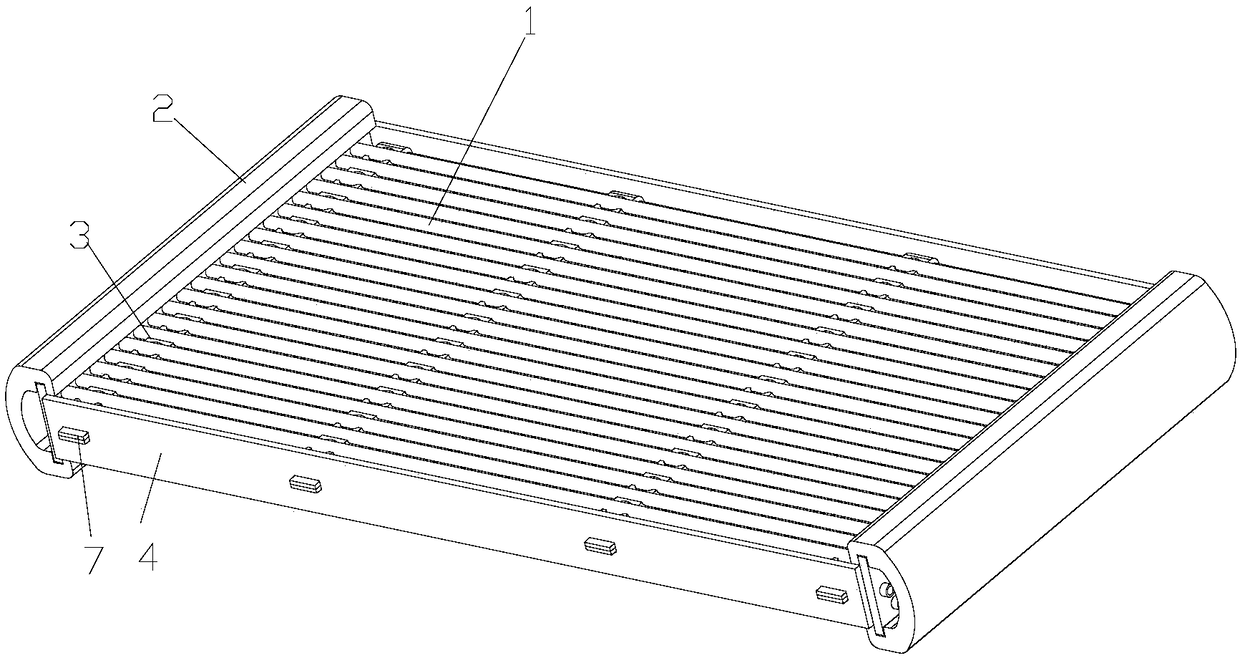

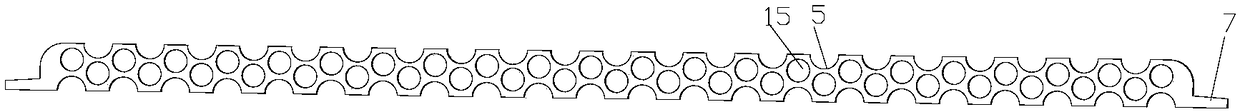

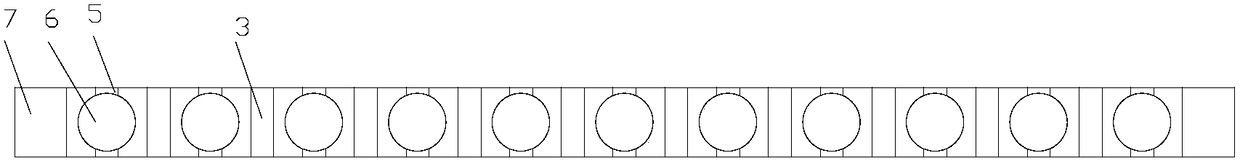

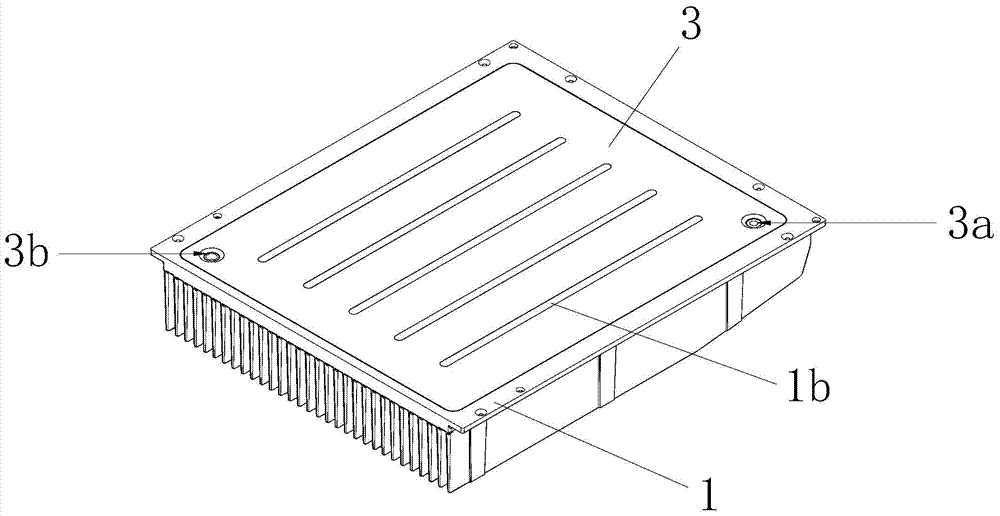

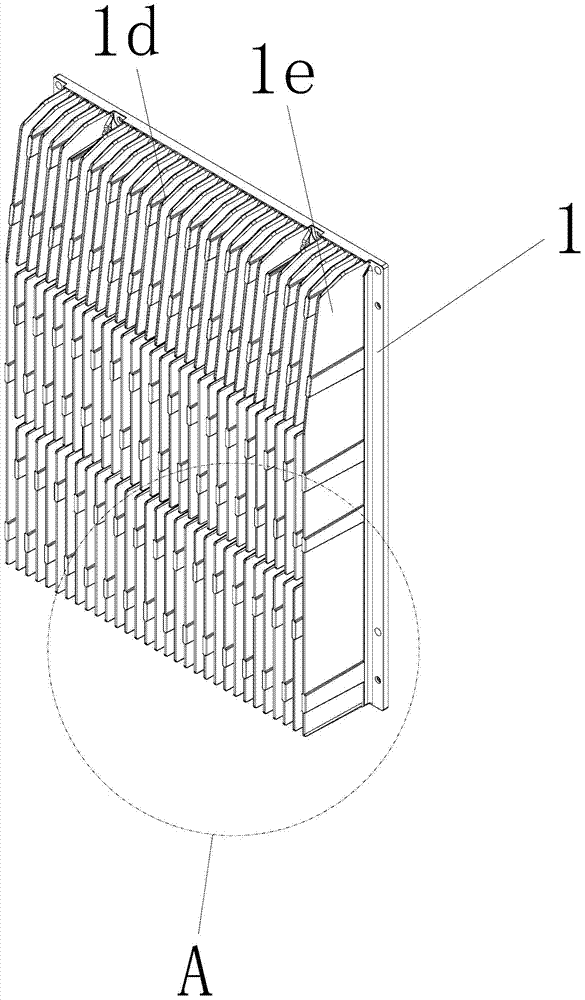

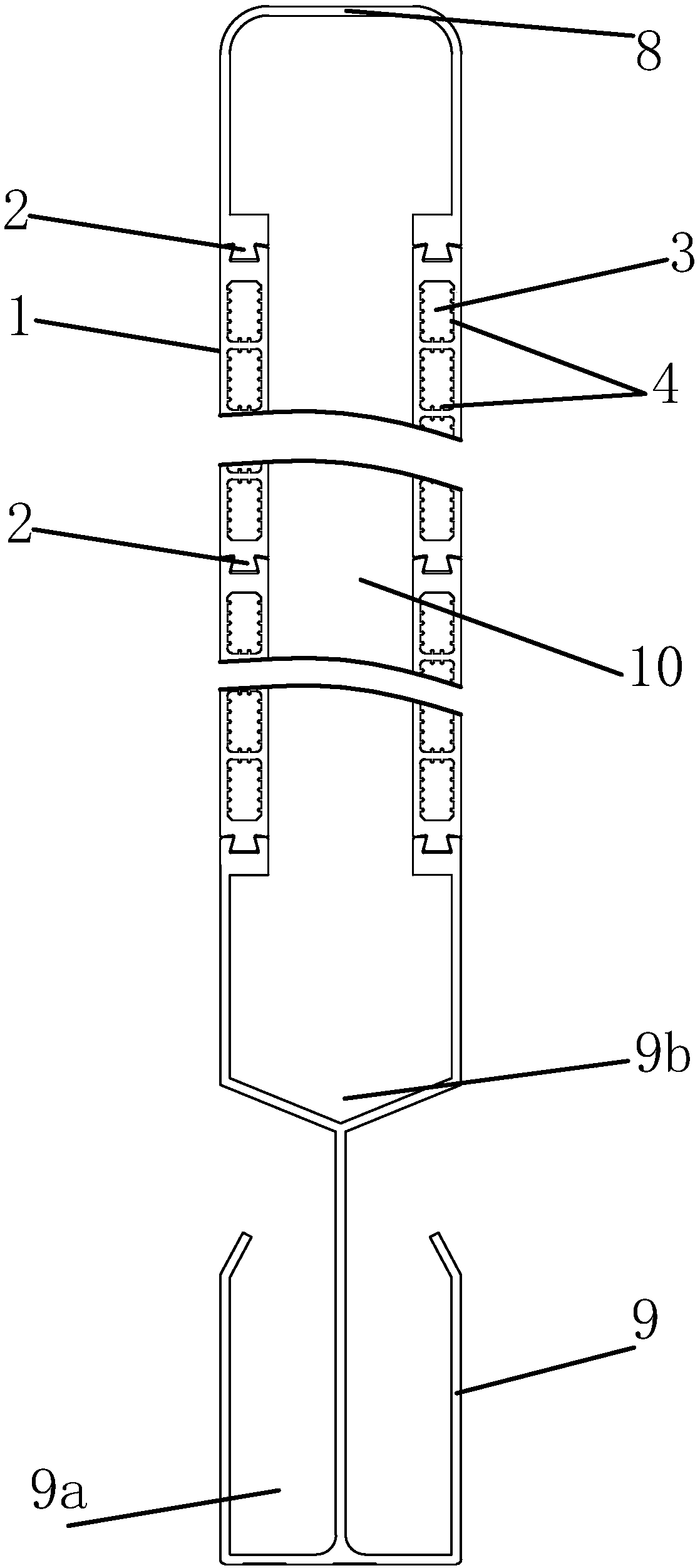

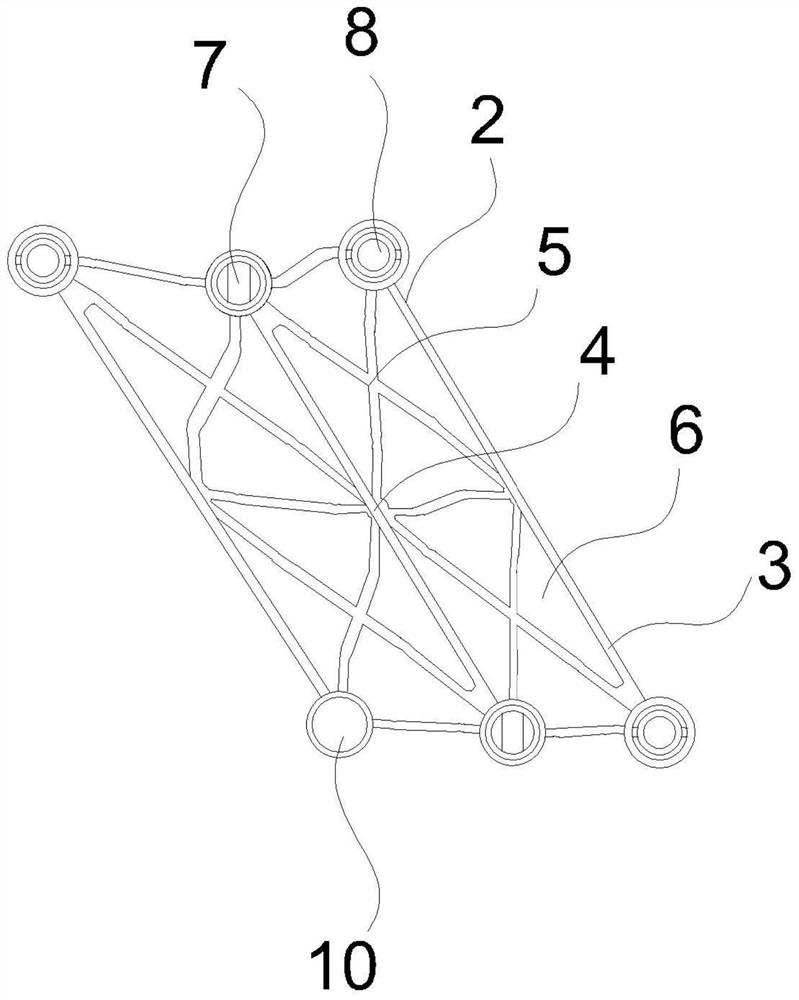

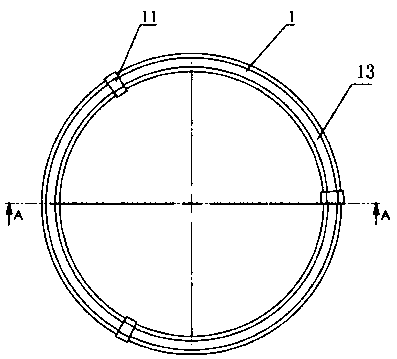

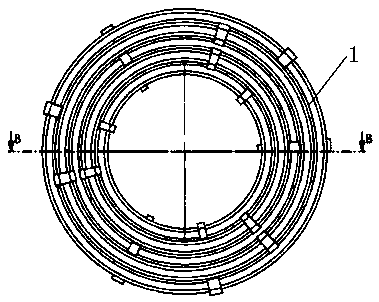

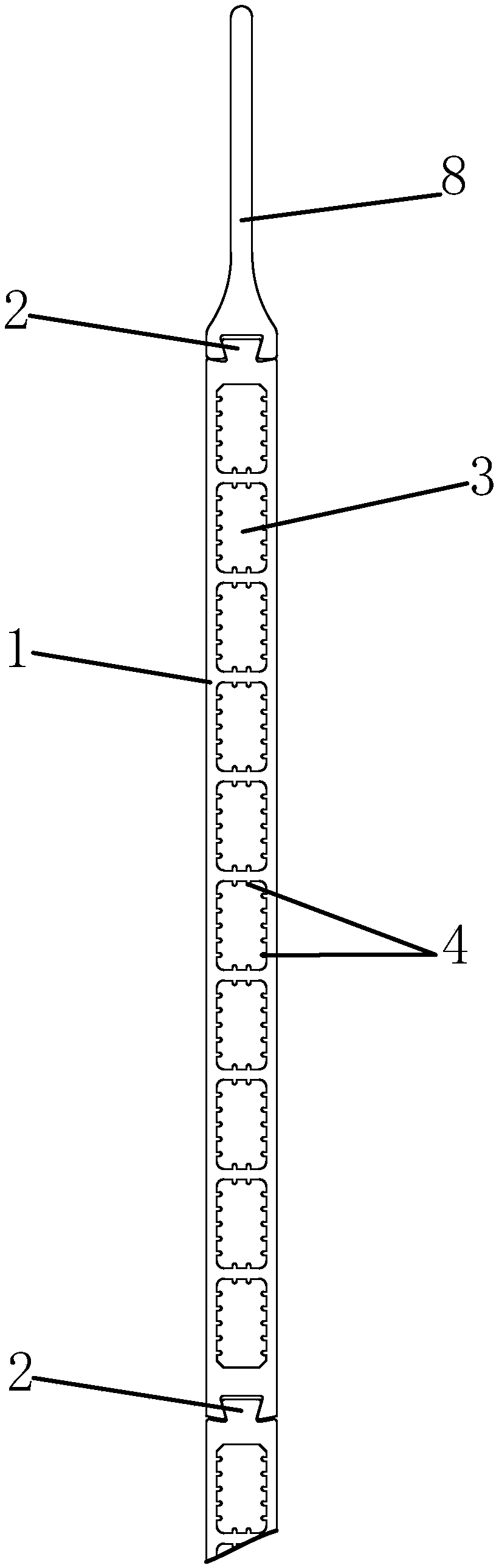

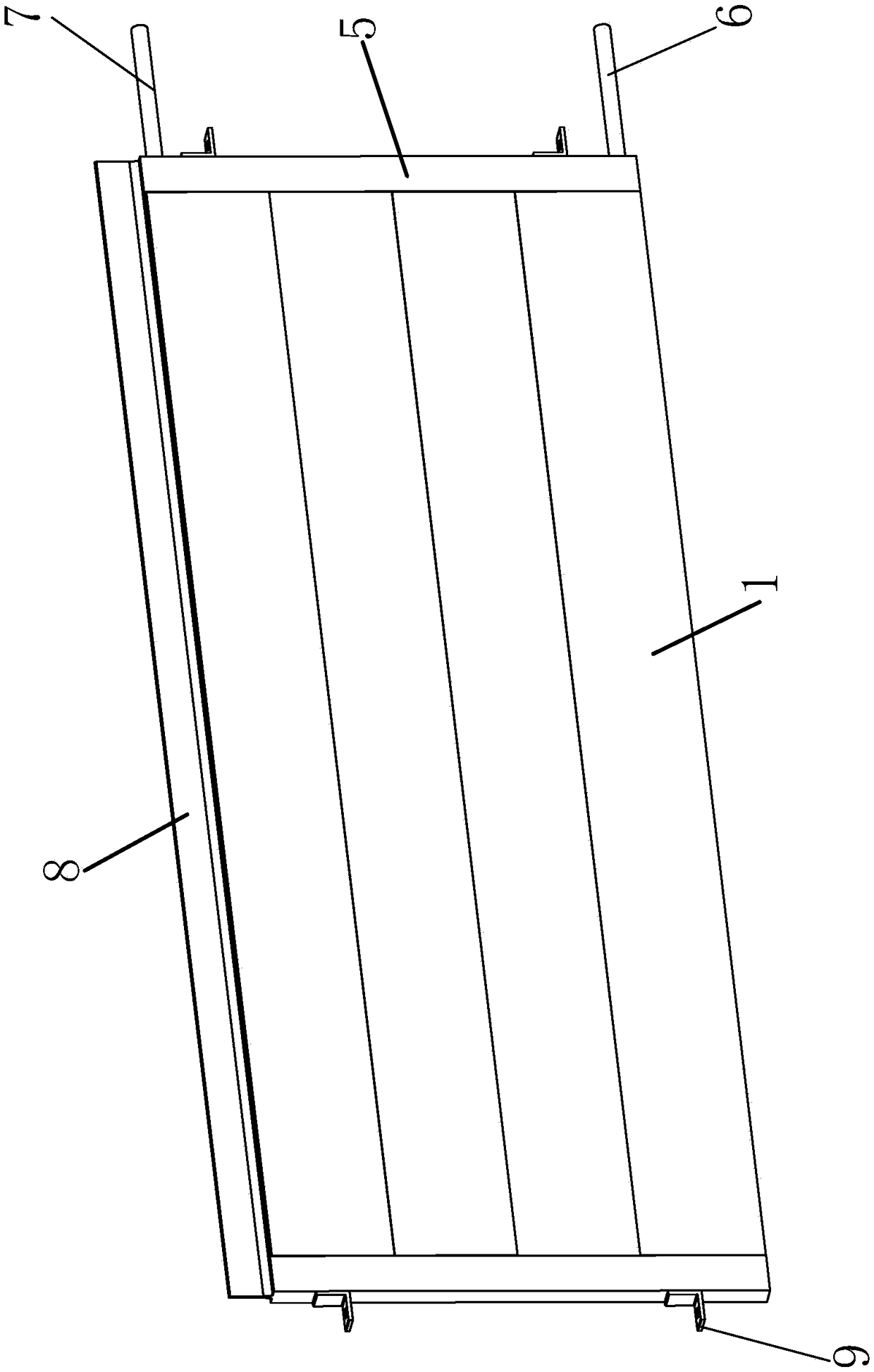

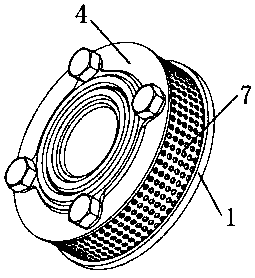

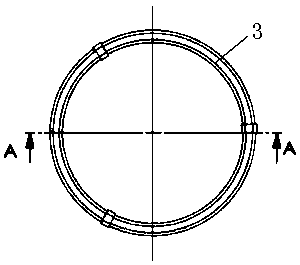

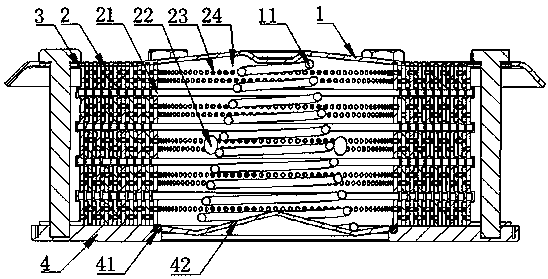

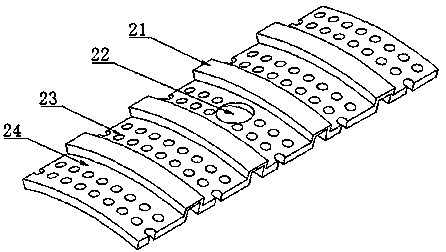

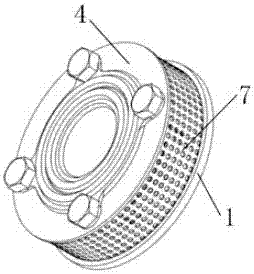

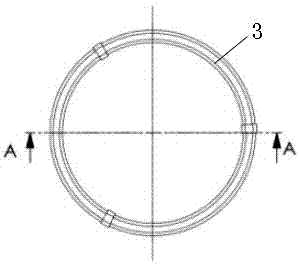

Capillarity pipe heat exchanger

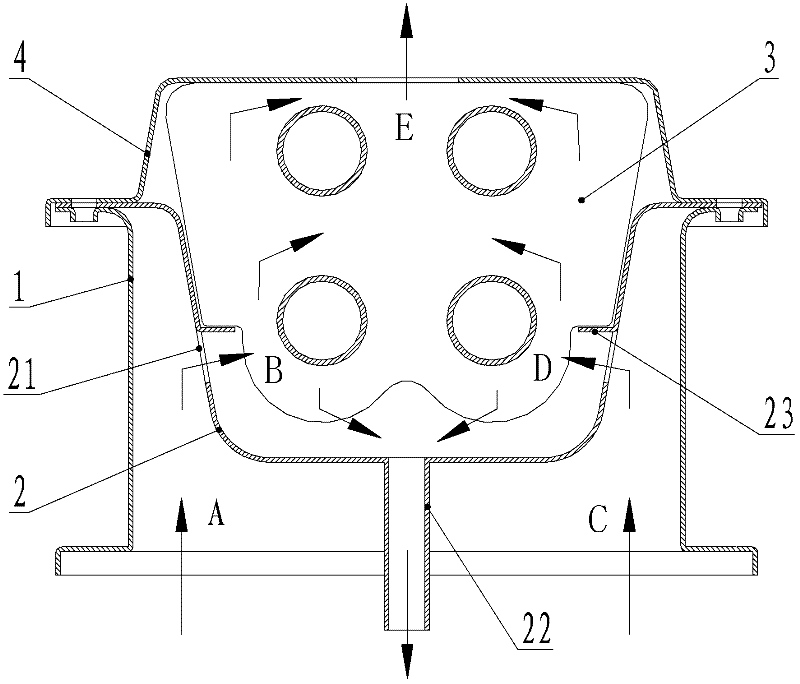

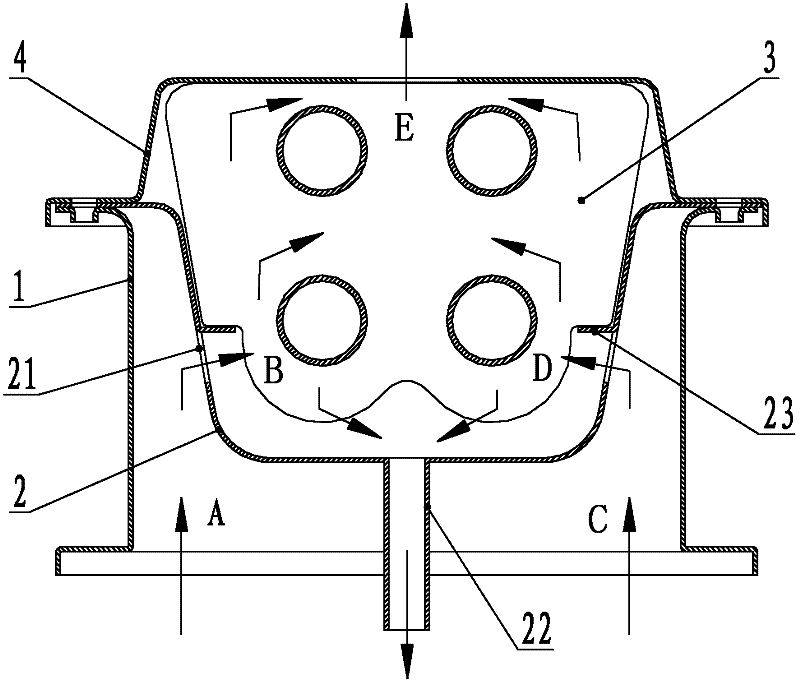

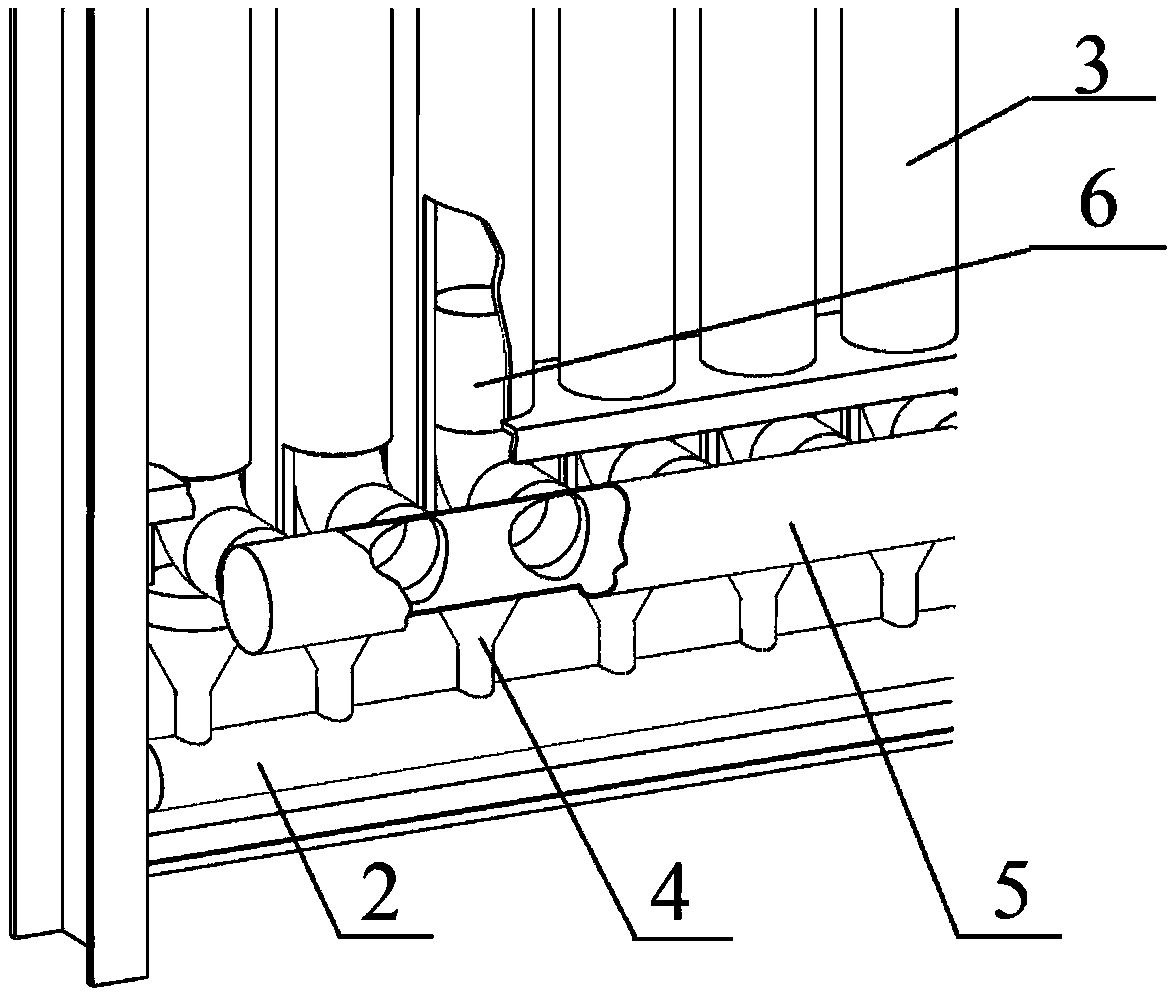

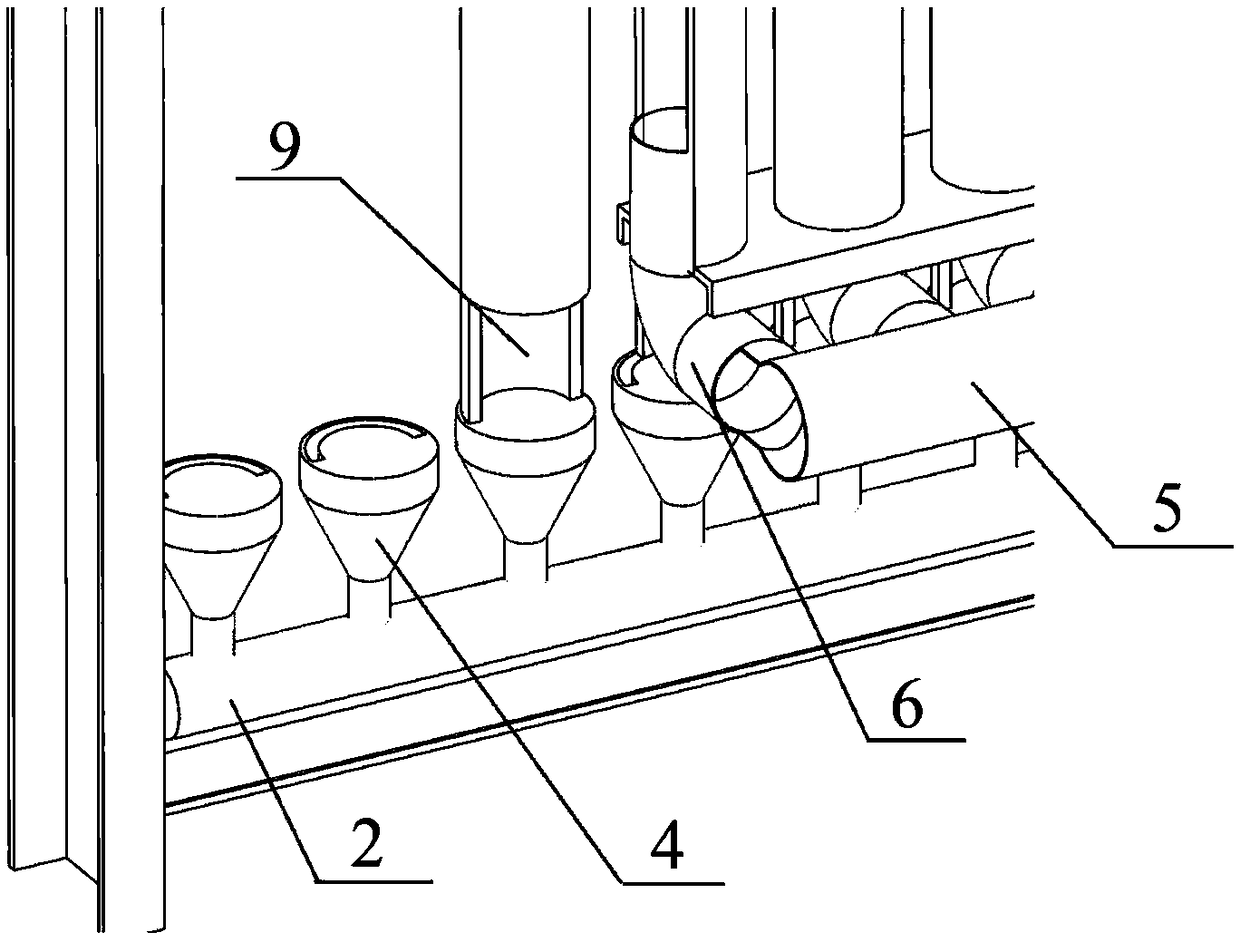

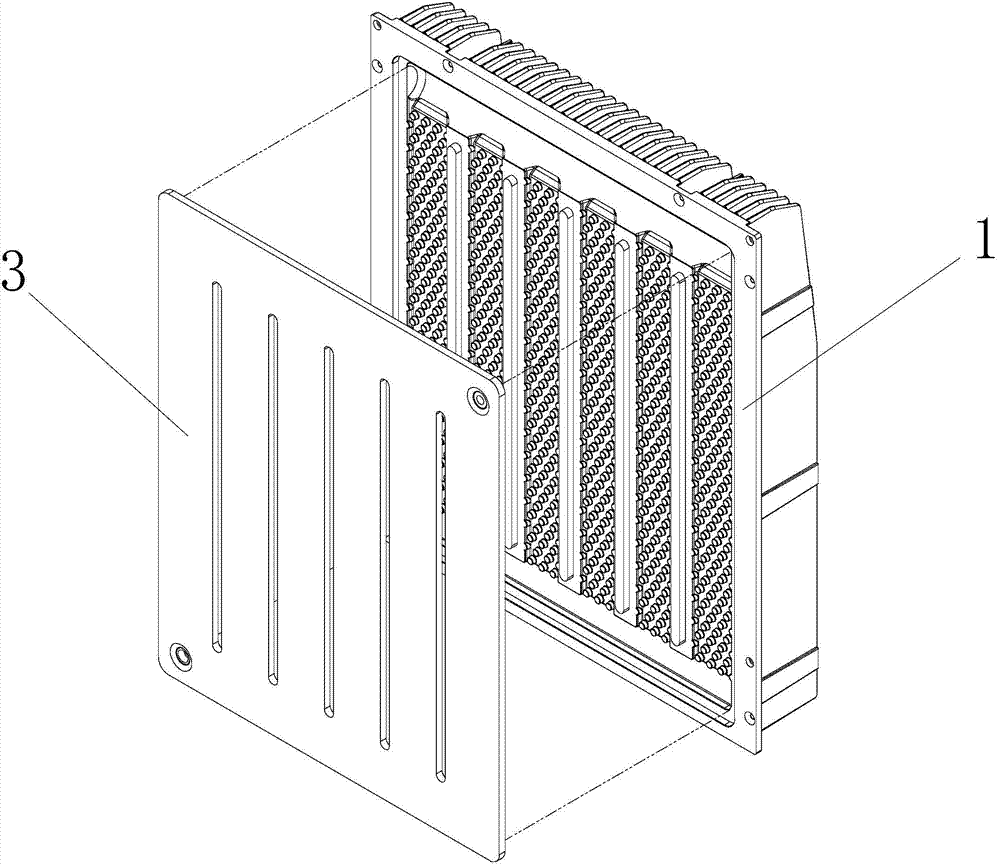

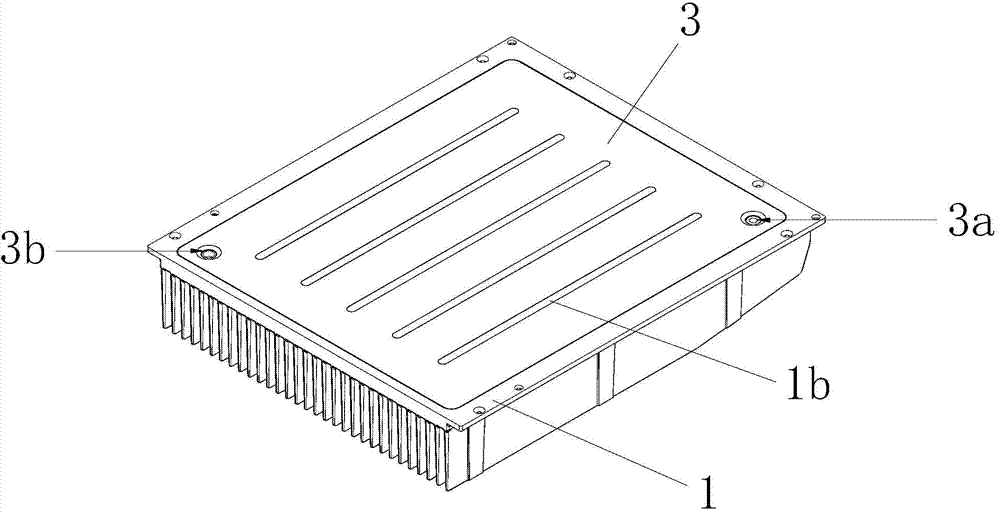

ActiveCN108731508AAvoid problems such as bent capillariesGuaranteed molding effectStationary conduit assembliesEngineeringRefrigerant

The invention provides a capillarity pipe heat exchanger. The capillarity pipe heat exchanger comprises multiple rows of capillarity pipes (1) and collecting pipes (2) located at the two ends of the capillarity pipes (1), wherein each row of capillarity pipes (1) comprise multiple capillarity pipes which are arranged at intervals and are supported and fixed by supporting blocks (3); the supportingblocks (3) extend in the distribution direction of each row of capillarity pipes (1); and the two ends of each supporting block (3) are fixed by side plates (4) arranged on the collecting pipes (2).The capillarity pipe heat exchanger can solve the problem in the prior art that the excessive large pipe diameter of a heat exchange pipe causes the reduction of the heat exchange efficiency of the heat exchanger and the relatively low utilization rate of refrigerants.

Owner:ZHEJIANG DUNAN MASCH CO LTD

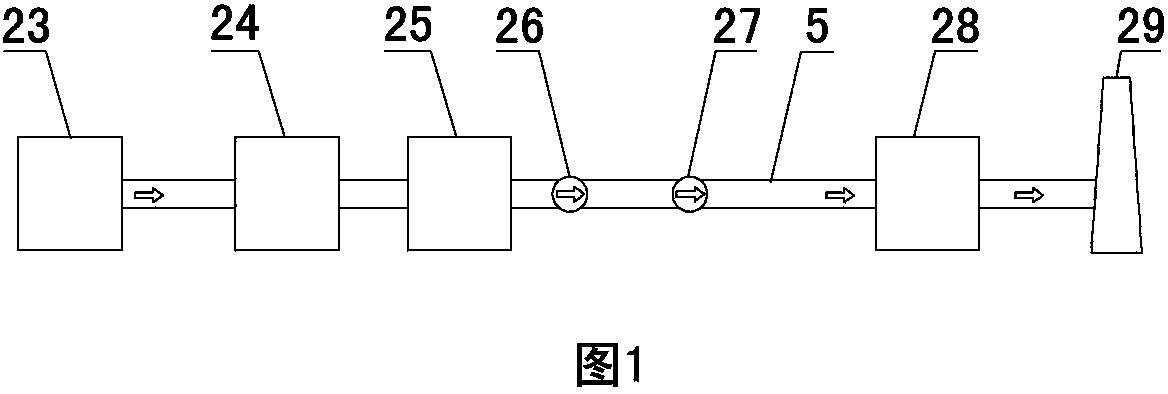

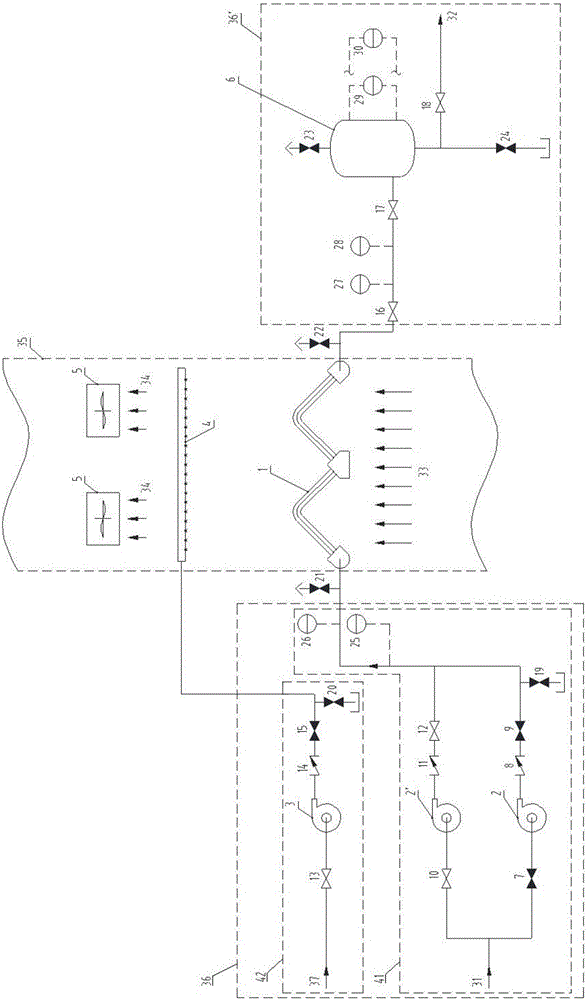

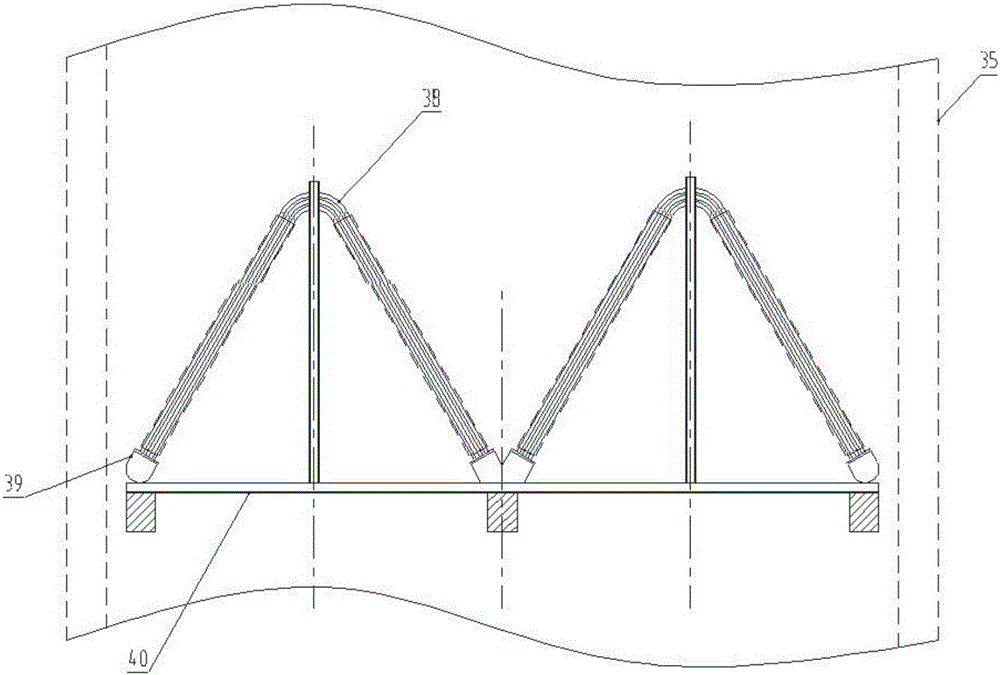

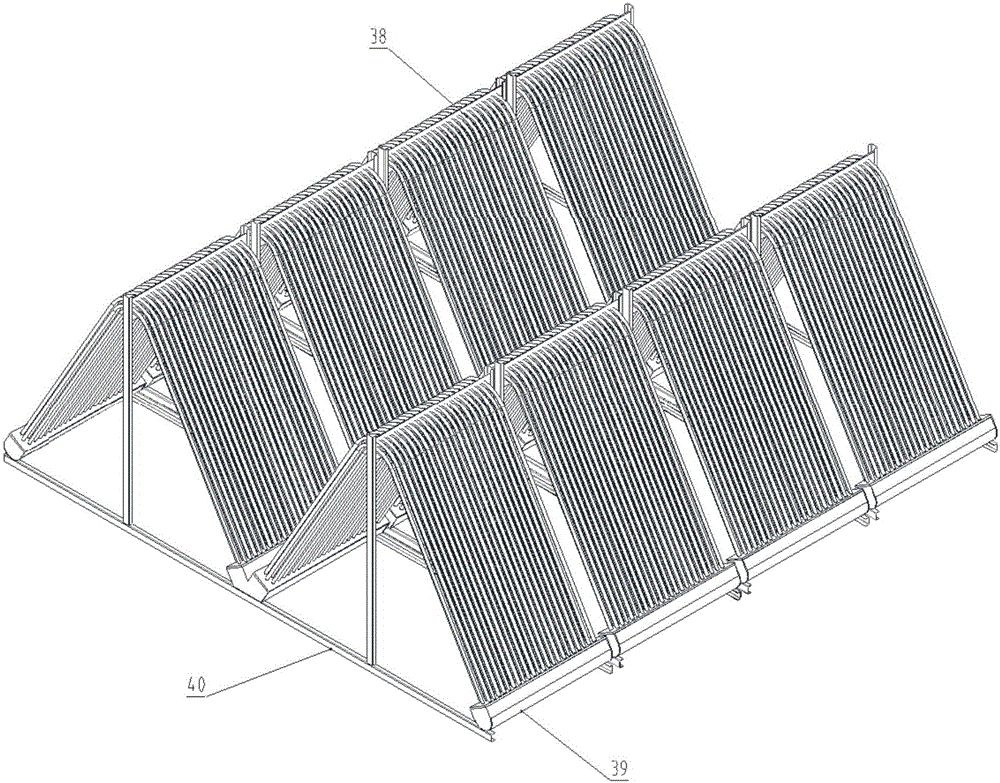

Flue-gas waste-heat recycling system

ActiveCN102607306BAvoid pollutionFlexible locationEnergy industryHeat exchanger casingsPlate heat exchangerFlue gas

A novel flue-gas waste-heat recycling system comprises a flue-gas heat exchanger, a water inlet pipe, a water outlet pipe, a water tank, a refrigerant medium water pump and a waste-heat using device and further comprises a secondary heat exchanger. The secondary heat exchanger further comprises a secondary heat exchanger casing and a secondary heat exchanger pipe arranged in the secondary heat exchanger casing. The flue-gas heat exchanger is a module type fluorine plastic pipe flue-gas heat exchanger, and positioning meshes are parallelly distributed in a flue-gas heat exchanger casing of the flue-gas heat exchanger at intervals from top to bottom. The novel flue-gas waste-heat recycling system avoids pollution of a finally-heated medium, and the using of the final waste-heat using device is not influenced. The flue-gas heat exchanger is the module type fluorine plastic pipe flue-gas heat exchanger, and accordingly the flue-gas heat exchanger is easy to operate and manage. The positioning meshes are arranged in the module type fluorine plastic pipe flue-gas heat exchanger, and shaking and deformation of a flexible fluorine plastic heat exchange pipe bundle under the flowing impact of flue gas can be avoided.

Owner:北京新世翼节能环保科技股份有限公司

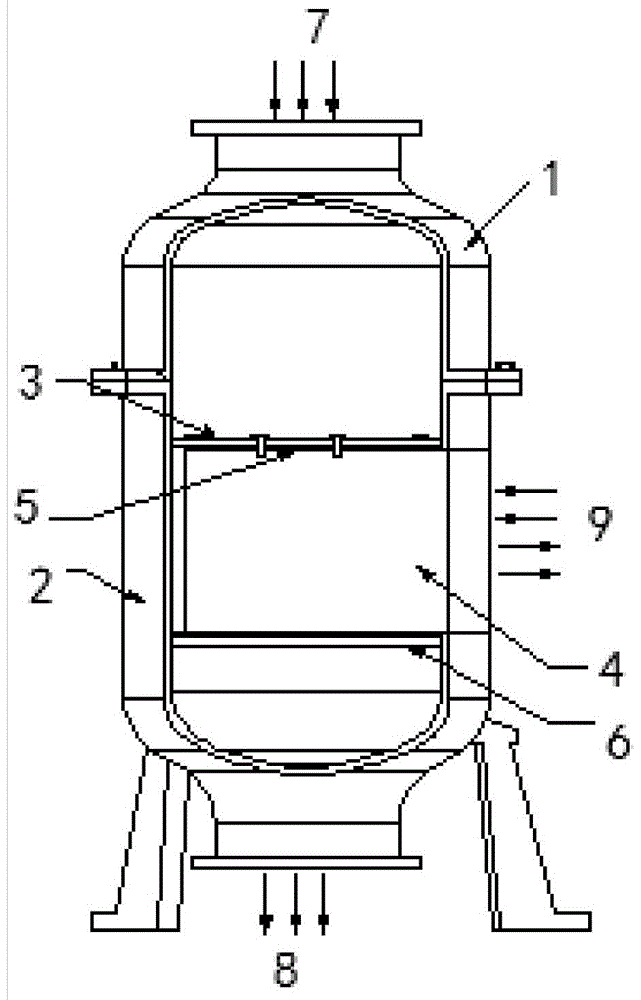

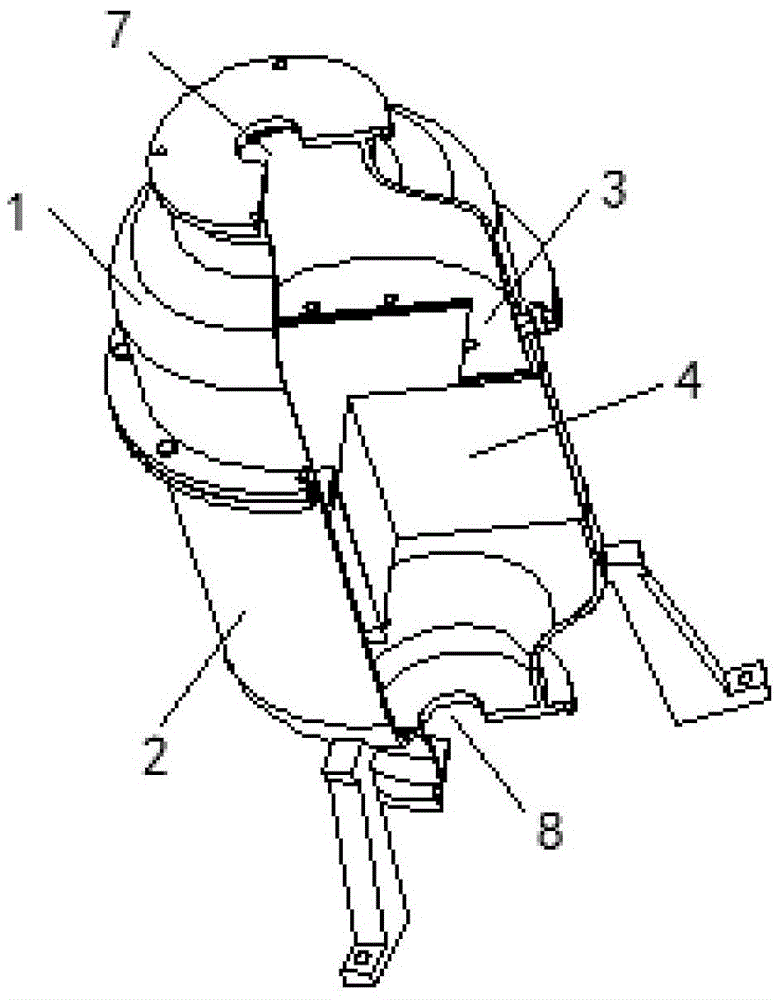

Air cooling device

ActiveCN103900314AFull contact heat transferImprove cooling efficiencyDomestic cooling apparatusLighting and heating apparatusEngineeringHeat sink

The invention relates to an air cooling device. The air cooling device comprises an upper barrel, a lower barrel, a first sealing steel plate and a cooler core, wherein the upper barrel is connected with the lower barrel; an accommodating cavity is formed between the upper barrel and the lower barrel; the first sealing steel plate is arranged in the accommodating cavity; the outer edge of the first sealing steel plate is hermetically connected with the inner wall of the lower barrel; an opening is formed in the first sealing steel plate; the cooler core is arranged below the first sealing steel plate and is positioned in the accommodating cavity; the sizes and the positions of radiating fins of the cooler core are matched with the size and the position of the opening in the first sealing steel plate; and the cooler core is hermetically connected with the first sealing steel plate. Because the outer edge of the first sealing steel plate is hermetically connected with the inner wall of the lower barrel, hot air entering the air cooling device enters the cooler core from the opening in the first sealing steel plate. The square air inlet of the cooler core and a circular gap between the upper barrel and the lower barrel can be sealed by using the first sealing steel plate; and the cooling efficiency is improved.

Owner:YANCHENG INST OF TECH

Waste heat recovery system of quenching tower

ActiveCN106433697ABy the way wash offIncrease the heat exchange areaCoke quenchingEnergy inputWaste heat recovery unitSocial benefits

The invention discloses a waste heat recovery system of a quenching tower. The waste heat recovery system comprises water inlet pipelines, the quenching tower and a water outlet pipeline. The water inlet pipelines comprise a supply water pipeline and a cleaning water pipeline; the quenching tower comprises a waste heat recovery device, a cleaning pipe and an induced draft fan; a supply water inlet is formed in the head end of the supply pipeline, and the tail end of the supply water pipeline is connected with one end of the waste heat recovery device. A cleaning water inlet is formed in the head end of the cleaning water pipeline, and the tail end of the cleaning water pipeline is connected with the cleaning pipe. The head end of the water outlet pipeline is connected with the other end of the waste heat recovery device, and a hot water outlet is formed in the tail end of the water outlet pipeline. The problem of recovery and dust removal of a large amount of heat generated during quenching of the quenching tower of a coke plant is solved. The utilization rate of energy is increased by recycling heat in steam, discharged dust is reduced, dual indexes of energy saving and environmental protection are achieved, and economic benefits and social benefits are achieved.

Owner:QINGDAO JIENENG HIGH&NEW TECH

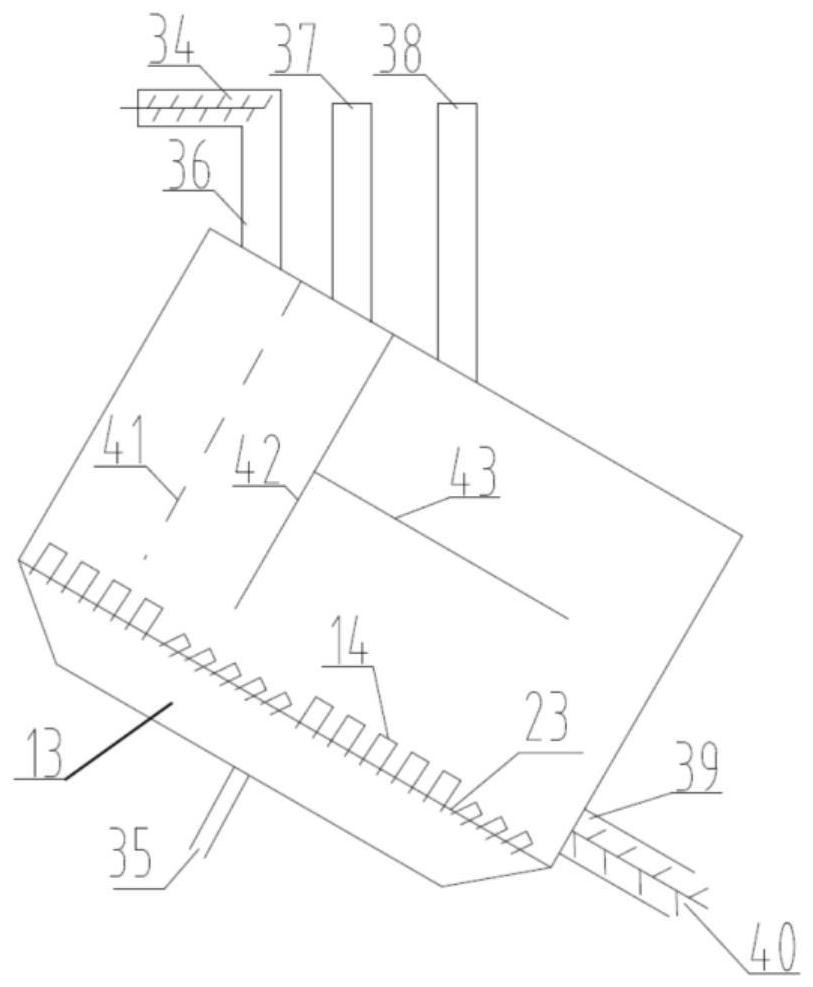

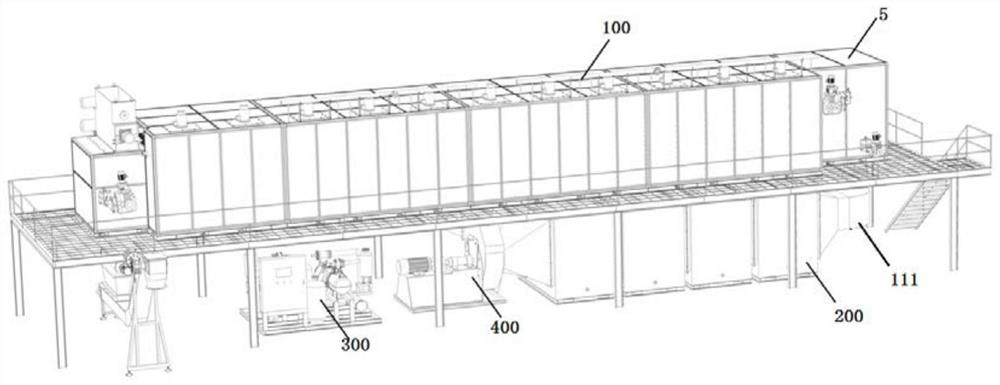

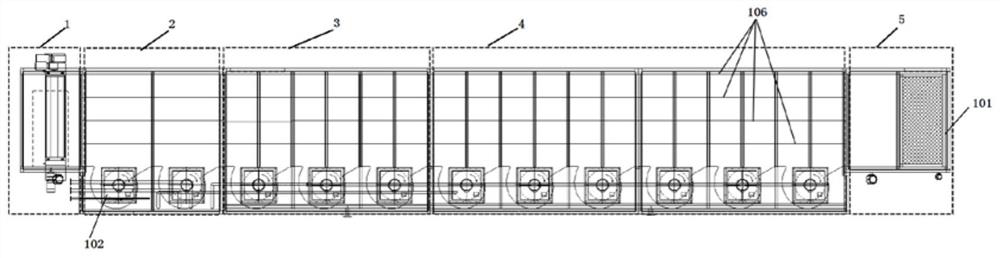

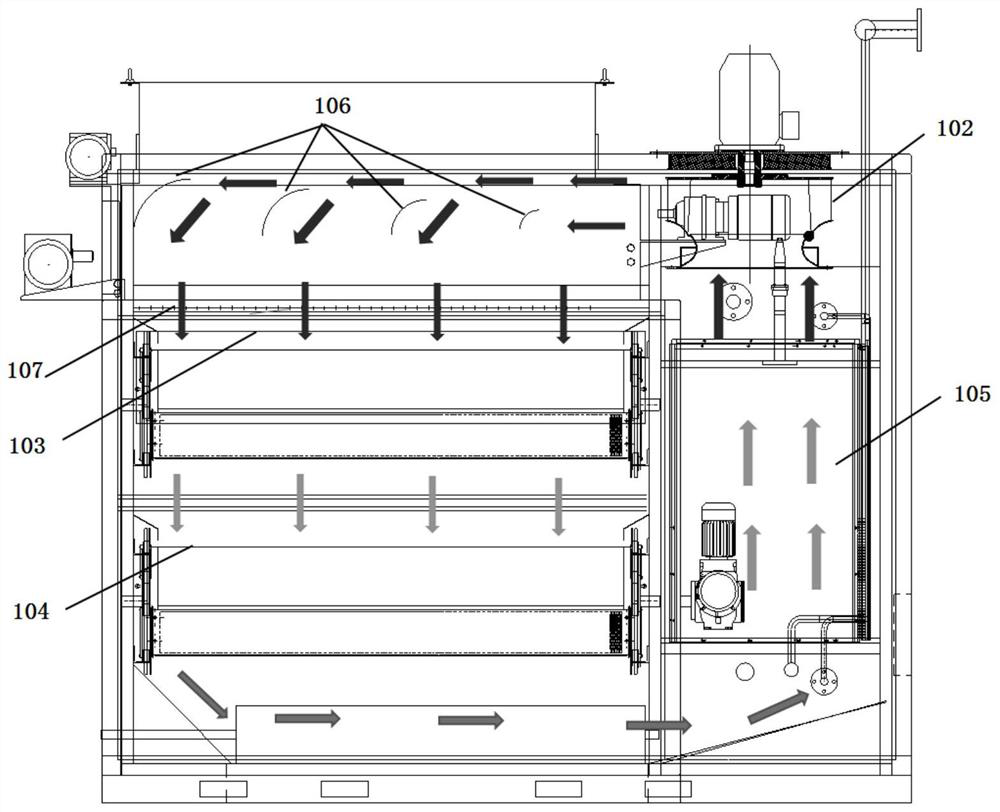

Air uniformizing and dust removing device for sludge drying equipment and sludge drying equipment

ActiveCN113371972AUniform contact heat transferFull contact heat transferCombination devicesSludge treatment by de-watering/drying/thickeningSludgeDust control

The invention relates to an air uniformizing and dust removing device for sludge drying equipment and the sludge drying equipment. The air uniformizing and dust removing device comprises a drying oven, an outer circulating air fan, a heat exchange skid and a dust removing system, wherein the drying oven, the outer circulating air fan and a heat exchange skid are communicated to form an outer circulating air channel; the drying oven is provided with a transmission mesh belt and an inner circulating air channel; a plurality of flow guide plates are arranged at the upper end of the inner circulating air channel and are used for guiding inner circulating air in the inner circulating air channel to the conveying mesh belt; an air uniformizing plate is arranged between the flow guide plates and the transmission mesh belt; and the drying oven and the heat exchange skid are connected through an outer circulating air return channel, and dust removal systems are arranged at the two ends of the outer circulating air return channel. Through the flow guide plates and the air uniformizing plate, inner circulating air can be in uniform and full contact with sludge at all positions on the conveying mesh belt for heat exchange, and the drying efficiency is improved.

Owner:北京清源华建环境科技有限公司

Immersed combustion evaporator

ActiveCN111870978AIncrease the heat exchange areaFull contact heat transferWater contaminantsEvaporator accessoriesCombustible gasEngineering

The invention provides a submerged combustion evaporator which comprises a tank body used for receiving to-be-evaporated feed liquid; a heat conduction cavity used for combusting combustible gas and combustion-supporting gas to generate smoke, wherein at least part of the heat conduction cavity is arranged in the tank body, and an exhaust port is formed in the bottom of the heat conduction cavity;and a gas distribution assembly which comprises a pressurizer and a flow guide plate, wherein the pressurizer and the flow guide plate are both arranged below the exhaust port, the flow guide plate is in an inverted conical barrel shape, a plurality of through holes are formed in the flow guide plate, and the pressurizer can block part of gas exhausted from the exhaust port, so that the gas flowsobliquely upwards along the flow guide plate, and the other part of gas can flow upwards through the through holes of the guide plate. By the adoption of the technical scheme, the heat exchange areaof feed liquid and gas is increased, high-temperature gas generated by combustion can make full contact with the feed liquid for heat transfer, the heat transfer efficiency and the evaporation rate are improved, and therefore the gas consumption of equipment is reduced, and energy is saved.

Owner:TSINGHUA UNIV

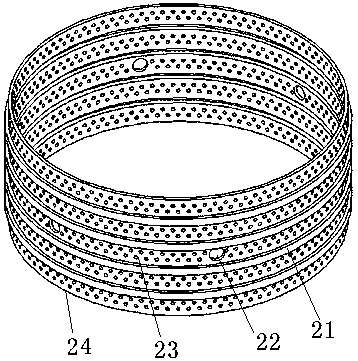

Flame-retardant type anti-explosion valve of crankcase

ActiveCN107559088ASimple structureEasy to produceMachines/enginesEngine componentsCrankcaseEngineering

The invention discloses a flame-retardant type anti-explosion valve of a crankcase. The flame-retardant type anti-explosion valve of a crankcase comprises a valve deck and a valve seat. A valve clackis arranged on the valve seat. An inner flame-retardant ring group, an outer flame-retardant ring and a spring are arranged between the valve deck and the valve seat. The upper end of the spring is fixed to the valve deck. The lower end of the spring tightly presses the valve clack. The inner flame-retardant ring group and the outer flame-retardant ring are arranged in the space formed by the valve deck and the valve seat to form a flame retardant device. Because the flame-retardant type anti-explosion valve of a crankcase is adopted, the airflow through holes of the valve are evenly distributed along the surfaces of ring bodies, the airflow through holes of the same ring body are evenly arranged side by side, the airflow through holes of two adjacent ring bodies stagger to form labyrinthtype bend channels, the time for airflow and flames to pass through can be effectively prolonged while heat exchange between airflow and the inner walls of the flame retardant rings can be sufficient,the use ratio of the flame retardant rings is increased to the maximum degree, the temperature is lowered, and the purposes of reducing pressure and putting out flames are achieved finally. The flame-retardant type anti-explosion valve of a crankcase is simple in structure, and easy to produce and install. The problems exist in an anti-explosion valve can be solved. The flame-retardant type anti-explosion valve of a crankcase has broad application prospects.

Owner:ZHEJIANG UNIV OF TECH

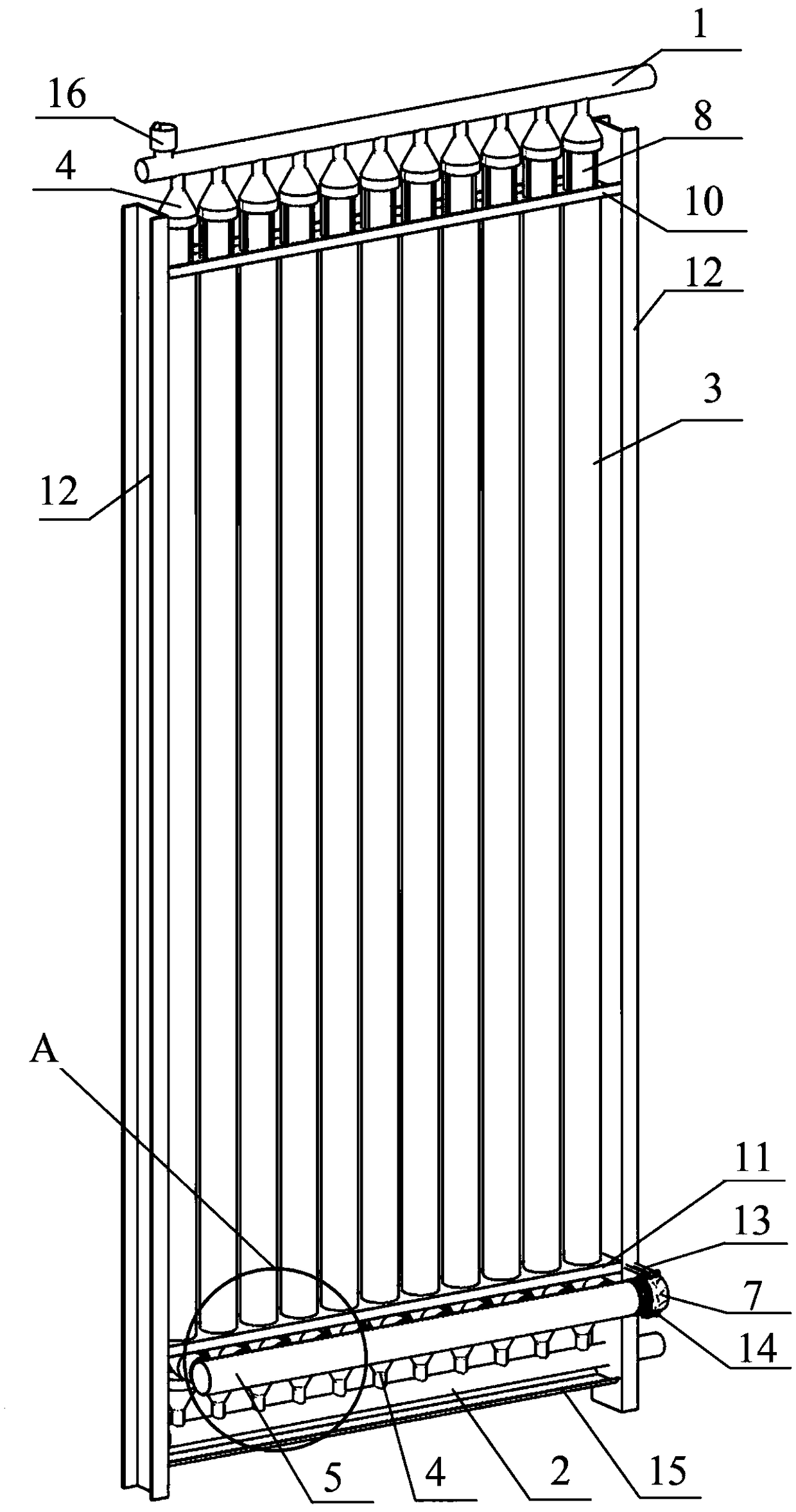

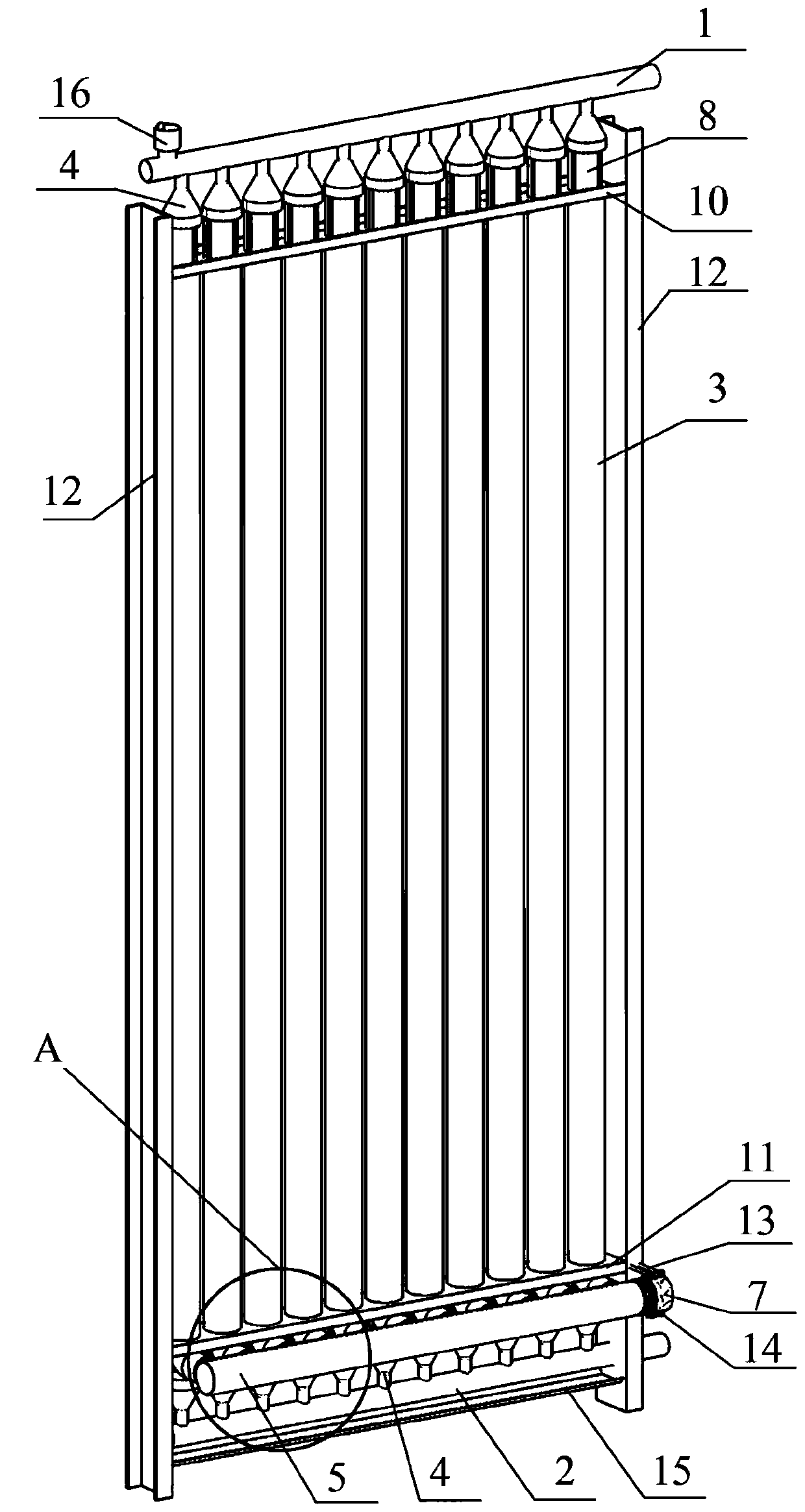

Narrow ring gap heat exchange air conditioning terminal device

ActiveCN108981120AImprove heat transfer effectNo obvious blowing sensationDucting arrangementsLighting and heating apparatusTerminal equipmentEngineering

The invention discloses a narrow ring gap heat exchange air conditioning terminal device, and relates to the technical field of heating ventilation air conditioning system terminal devices. The terminal device comprises an installation frame, a water system and an air system; the water system comprises an upper header pipe, a lower header pipe and heat exchange pipes, and the multiple heat exchange pipes are vertically fixed to the installation frame; each heat exchange pipe comprises an inner pipe and an outer casing pipe, and the inner pipe is fixed in the outer casing pipe; a liquid flow channel is formed between each inner pipe and each outer casing pipe, and an air flow channel is formed in each inner pipe; the two ends of each liquid flow channel communicate with the upper header pipe and the lower header pipe separately; the air system comprises an air main pipe and a ducted fan connected to the air main pipe, and the air main pipe communicates with the air flow channel; and oneside of the top of each heat exchange pipe is provided with an upper air opening, and the air flow channel communicates with outside through the upper air opening. According to the terminal device, on the premise of ensuring that a working area of personnel has no obvious blowing feeling, the heat exchange effect can be improved, and the heat exchange capability of the air conditioning terminal device is improved; and the terminal device has the functions of heating in winter and cooling in summer.

Owner:DALIAN UNIV OF TECH

Condenser

InactiveCN104776652AImprove condensation efficiencyGuaranteed connection strengthEvaporators/condensersEngineeringOpen cavity

The invention discloses a condenser. The condenser comprises a condenser body which is provided with an open cavity, wherein a cover plate which is arranged at an opening of the open cavity and is used for sealing the open cavity is fixedly arranged on the condenser body, the open cavity consists of a liquid inlet chamber, a liquid through chamber and a liquid outlet chamber which are sequentially distributed from front to back, a liquid inlet hole communicated with the liquid inlet chamber and a liquid outlet hole communicated with the liquid outlet chamber are formed in the cover plate, and a plurality of flow blocking bulges which are densely distributed in the liquid through chamber and are of staggered distribution are formed on the condenser body. The condenser disclosed by the invention is light and small in body type and extremely high in condensing efficiency.

Owner:苏州东山昆拓热控系统有限公司

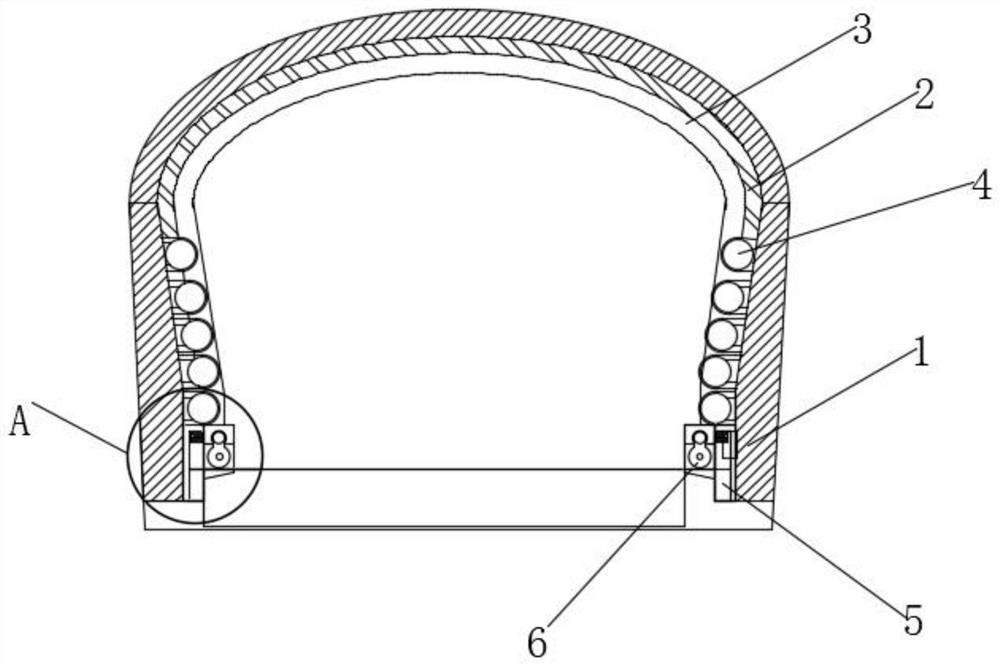

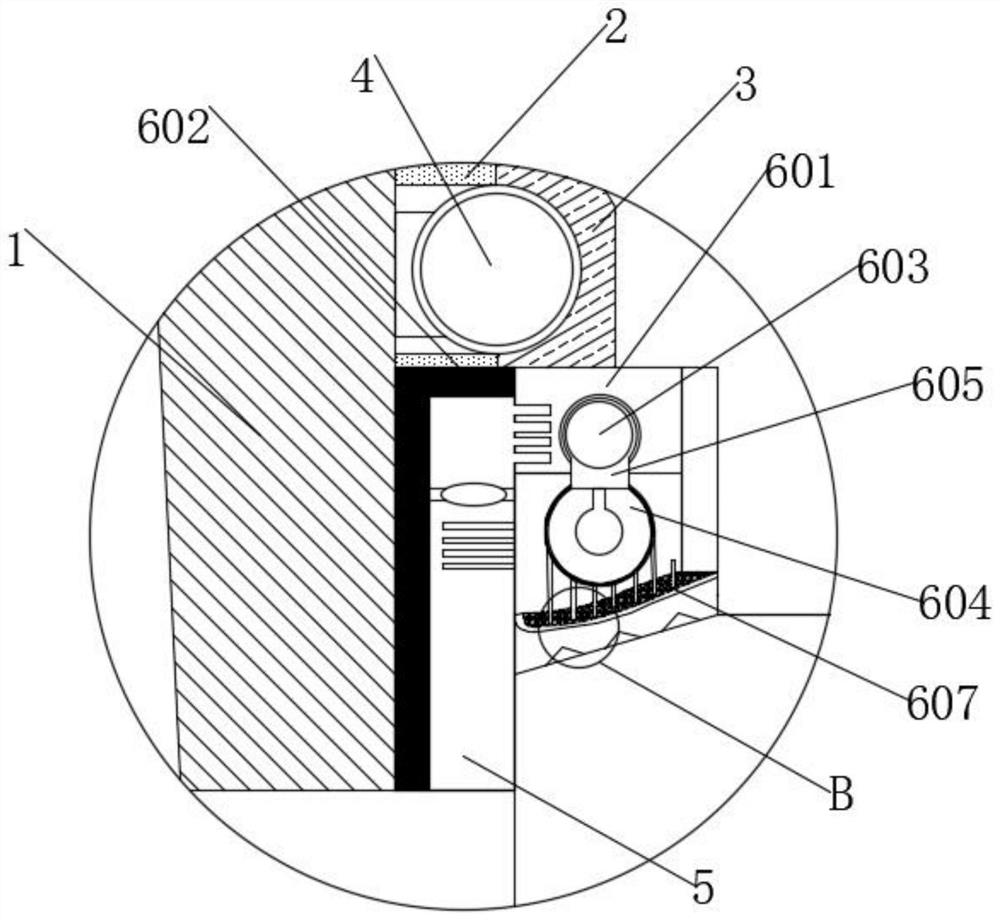

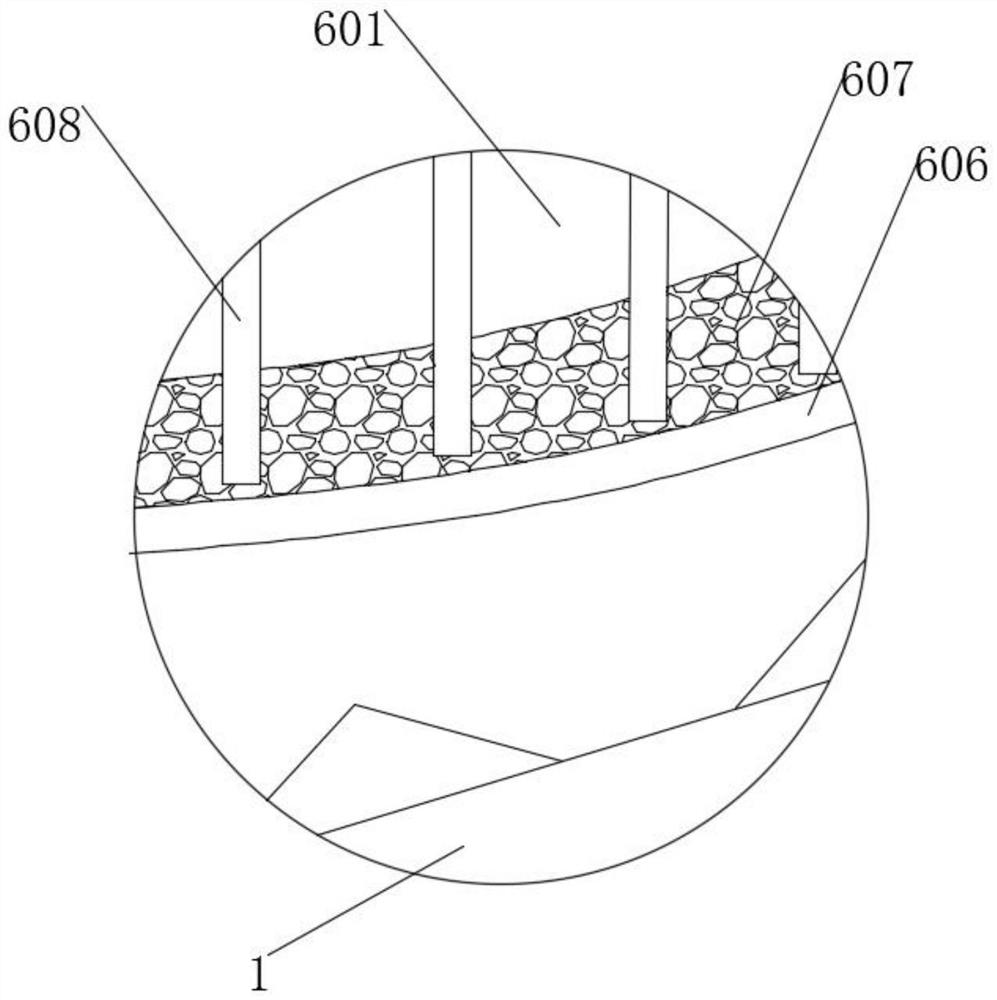

Tunnel insulation ditch heating system using ground source heat pump

InactiveCN111794801AStable temperatureIncrease temperatureMining devicesDrainageInsulation layerHeat conservation

The invention discloses a tunnel insulation ditch heating system using a ground source heat pump, and belongs to the field of ground source heat pumps. The tunnel insulation ditch heating system usingthe ground source heat pump comprises a tunnel main body, and a pair of drainage channels is formed in the bottom end of the inner wall of the tunnel main body in a digging mode; the inner wall of the tunnel main body is fixedly connected with an insulation layer, and the insulation layer is fixedly connected with an installation layer; a plurality of heat exchange pipes uniformly distributed areconnected between the insulation layer and the installation layer, and a heat source ground pump main body is installed on the heat exchange pipes; insulating pipes matched with the drainage channelsare installed in the tunnel main body, and heat storage pipes are arranged on the lower sides of the insulating pipes; and heat conduction plates are connected between the insulting pipes and the heat storage pipes, and the bottom ends of insulation boards are fixedly connected with heat exchange films. According to the scheme, through storage of a part of heat released from a heat source groundpump in a tunnel, the interior of the drainage channels in the tunnel remains at higher temperature, and water flow entering the drainage channels in the tunnel is subjected to heat treatment throughthe insulating pipes; and when cold water flow in the tunnel is in contact with insulated water flow in the drainage channels, fogging is avoided.

Owner:成都鑫筑博建材有限公司

condenser

InactiveCN104776652BImprove condensation efficiencyGuaranteed connection strengthEvaporators/condensersEngineeringOpen cavity

Owner:苏州东山昆拓热控系统有限公司

A narrow-gap heat exchange air conditioner terminal device

ActiveCN108981120BImprove heat transfer effectNo obvious blowing sensationDucting arrangementsLighting and heating apparatusThermodynamicsTerminal equipment

Disclosed is an air conditioning terminal device with heat exchange in a narrow annular space, relating to the technical field of terminal devices of heating, ventilation and air conditioning systems. The terminal device comprises an installation frame, a water system and an air system. The water system comprises an upper header pipe, a lower header pipe and heat exchange tubes, wherein the multiple heat exchange tubes are vertically fixed on the installation frame, each of the heat exchange tubes comprises an inner tube and an outer sleeve, the inner tube is fixed inside the outer sleeve, a liquid flow channel is formed between the inner tube and the outer sleeve, an air flow channel is formed inside the inner tube, and two ends of the liquid flow channel are respectively in communication with the upper header pipe and the lower header pipe. The air system comprises a main air tube and a ducted fan, wherein the ducted fan is connected to the main air tube, the main air tube is in communication with the air flow channel, one side of the top of each of the heat exchange tubes is provided with an upper air opening, and the air flow channel is in communication with the exterior by means of the upper air opening. The device can enhance the heat exchange effect and improve the heat exchange capability of the air conditioning terminal device while ensuring there is no obvious blowing feeling in a working area for workers, and also has the functions of heating in winter and cooling in summer.

Owner:DALIAN UNIV OF TECH

Plate ice machine with dual-plate evaporator and running method of plate ice machine

InactiveCN108302850AExtend the length of the flow pathExtend the length of stayIce productionEvaporators/condensersSingle plateEvaporation

The invention provides a plate ice machine with a dual-plate evaporator and a running method of the plate ice machine. A machine body shell of the plate ice machine is internally provided with a refrigeration system, an ice making water conveying system, a deicing water conveying system and an ice breaking mechanism; the evaporator comprises a plurality of evaporation dual plates, each evaporationdual plates comprise two opposite evaporation single plates, an overheating gap is formed between every two corresponding evaporation single plates, each evaporation single plate comprises a plurality of unit plate bodies, a plurality of circulation channels are arranged in the unit plate bodies in parallel, the cross sections of the circulation channels are rectangular, the inner walls of the circulation channels are evenly provided with a plurality of beads, plugging plates are fixedly installed on the two sides of each unit plate body, cavities are arranged in the plugging plates, the circulation channels communicate with the cavities, one ends of the cavities in the plugging plates are opened, the other ends of the cavities in the plugging plates are provided with closed plates, and openings of the cavities of the two plugging plates on each unit plate body are reversely arranged up and down; and the multiple unit plate bodies are fixedly connected through splicing assemblies in atandem manner, the plugging plates of every two adjacent unit bodies up and down are connected in an aligned manner, and the openings of the cavities of the plugging plates are in sealed communication.

Owner:青岛华友冰雪制冷工程有限公司

Multi-dimensional efficient packing

The invention relates to the technical field of packing, in particular to multi-dimensional efficient packing which comprises a packing body. The packing body is formed by assembling multiple packing sheets. Each packing sheet is integrally formed by arranging multiple packing units in a matrix manner, and each packing unit comprises two first frameworks and a second framework. The first frameworks and the second framework of each packing unit are parallel to one other, cross frameworks are arranged between the first frameworks and the second frameworks, and water film holes are formed between the cross frameworks and the first frameworks and between the cross frameworks and the second frameworks. Fixing structures or reinforcing structures are arranged at the vertex angles of the packing units, the multiple packing sheets are detachably assembled through the fixing structures to form the packing body, and multiple prismatic runners are formed in the packing body. The packing can be cleaned and repeatedly used, the service life is long, in the packing runners, no impurities are accumulated, no moss grows, the situations that packing heat exchange is uneven and the heat exchange efficiency is reduced in a cliff manner are avoided, and the packing replacement frequency and the existing packing wind resistance can be reduced.

Owner:重庆伊塞科节能环保科技有限公司

Flame retardant ring for explosion-proof valve

ActiveCN107575306BFull contact heat transferImprove flame extinguishing effectMachines/enginesEngine componentsEngineeringMechanical engineering

The invention discloses an explosion-proof valve anti-flaming ring. The ring comprises an anti-flaming ring boy and is characterized in that the anti-flaming ring body comprises a ring part and boss shoulders arranged on the ring part in a matched manner, the boss shoulders are evenly arranged along the circumference of the ring part, the cross section of the ring part is of a right hexagonal structure, a six-edge ring structure with the cross section in the right hexagonal shape is adopted in each boss shoulder, the radius of the anti-flaming ring body can be correspondingly adjusted throughthe size of the ring part, adjacent anti-flaming ring bodies with different radiuses can be in fit pressing connection through the side faces of the boss shoulders and the side face of the ring part,and the anti-flaming ring layer is formed. According to the anti-flaming ring, according to work requirements, the number of layers of anti-flaming rings can be adjusted, mounting flexibility is large, the shape is simple, production is easy, and production efficiency is high.

Owner:ZHEJIANG UNIV OF TECH

air cooling unit

ActiveCN103900314BFull contact heat transferImprove cooling efficiencyDomestic cooling apparatusLighting and heating apparatusEngineeringHeat sink

The invention relates to an air cooling device. The air cooling device comprises an upper barrel, a lower barrel, a first sealing steel plate and a cooler core, wherein the upper barrel is connected with the lower barrel; an accommodating cavity is formed between the upper barrel and the lower barrel; the first sealing steel plate is arranged in the accommodating cavity; the outer edge of the first sealing steel plate is hermetically connected with the inner wall of the lower barrel; an opening is formed in the first sealing steel plate; the cooler core is arranged below the first sealing steel plate and is positioned in the accommodating cavity; the sizes and the positions of radiating fins of the cooler core are matched with the size and the position of the opening in the first sealing steel plate; and the cooler core is hermetically connected with the first sealing steel plate. Because the outer edge of the first sealing steel plate is hermetically connected with the inner wall of the lower barrel, hot air entering the air cooling device enters the cooler core from the opening in the first sealing steel plate. The square air inlet of the cooler core and a circular gap between the upper barrel and the lower barrel can be sealed by using the first sealing steel plate; and the cooling efficiency is improved.

Owner:YANCHENG INST OF TECH

Plate ice machine with single-plate evaporator and operation method of plate ice machine

InactiveCN108286847AExtend the length of the flow pathExtend the length of stayIce productionEvaporators/condensersButt jointEvaporation

The invention provides a plate ice machine with a single-plate evaporator and an operation method of the plate ice machine. A refrigerating system and a water conveying system are arranged in the machine body shell of the plate ice machine, wherein the evaporator comprises a plurality of evaporation single plates; the evaporation single plates comprise a plurality of unit plate bodies, a pluralityof circulating channels are horizontally arranged in the unit plate bodies, and blocking plates are fixedly arranged on the two sides of the unit plate bodies; cavities are formed in the blocking plates, one ends of the inner cavities of the blocking plates are opened, sealing plates are arranged at the other ends, and the openings of the cavities of the two blocking plates on the same unit blocking plate are arranged in an up-and-down reversed mode; the plurality of unit plate bodies are fixedly connected through the splicing assembly in a longitudinal arranging mode, and the blocking platesof the upper and lower adjacent unit plate bodies are connected in a butt joint mode, so that the cavities of the connecting blocking plates are communicated in a sealed mode; liquid supply openingsare formed, in the blocking plates, of one sides of the unit plate bodies at the bottommost part, and liquid return openings are formed, in the blocking plates, of one sides of the unit plate bodies located at the uppermost part; and the liquid supply openings of the plurality of evaporation single plates are connected with liquid supply pipes in a collecting way, and the liquid return openings ofthe plurality of evaporation single plates are connected with the liquid return pipes.

Owner:青岛华友冰雪制冷工程有限公司

submerged combustion evaporator

ActiveCN111870978BIncrease the heat exchange areaFull contact heat transferEvaporator accessoriesWater contaminantsFlue gasCombustible gas

This application proposes a submerged combustion evaporator. The submerged combustion evaporator includes: a tank body, which is used to receive the material liquid to be evaporated; Partially arranged inside the tank body, the bottom of the heat conduction chamber is provided with an exhaust port; and an air distribution assembly, the air distribution assembly includes a supercharger and a deflector, both of which are arranged on the exhaust port Below, the deflector is formed into an inverted conical cylindrical shape, and the deflector is provided with a plurality of through holes. The supercharger can block a part of the gas discharged from the exhaust port, so that the gas flows obliquely upward along the deflector, and the other part Gas can flow upward through the through holes of the deflector. By adopting the above technical scheme, the heat exchange area of feed liquid and gas is increased, so that high-temperature gas and feed liquid generated by combustion can fully contact heat transfer, improve heat transfer efficiency and evaporation rate, thereby reducing equipment gas consumption and saving energy.

Owner:TSINGHUA UNIV

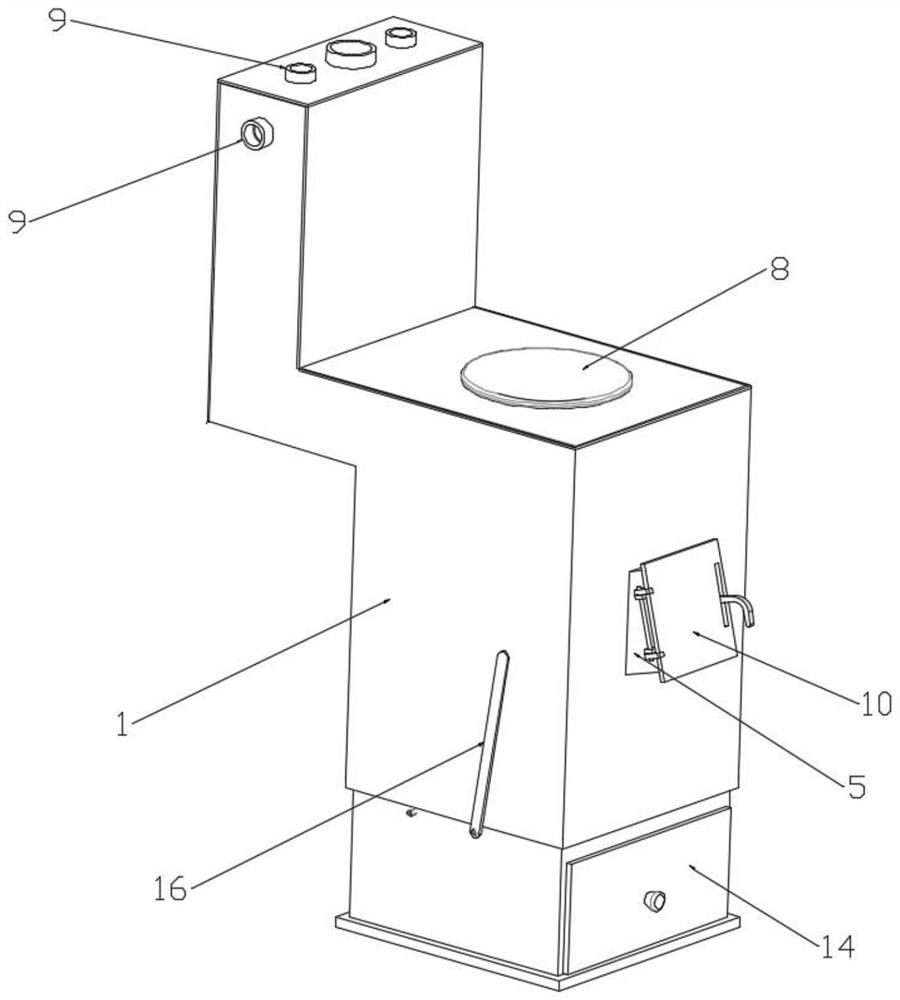

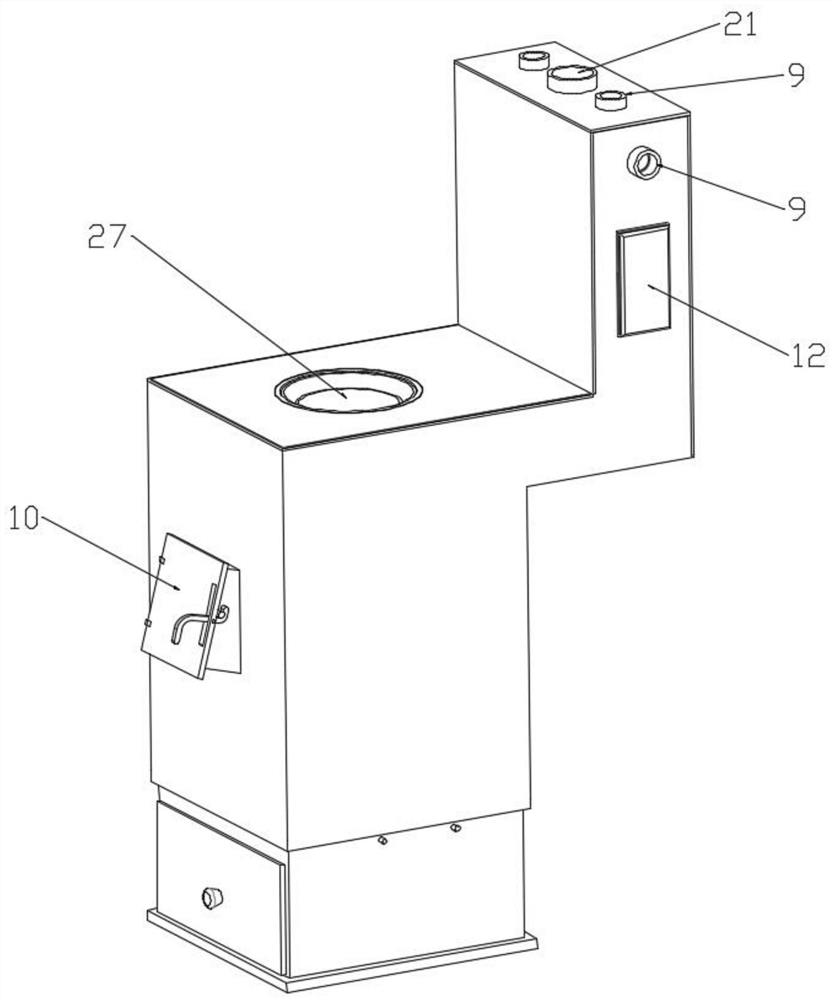

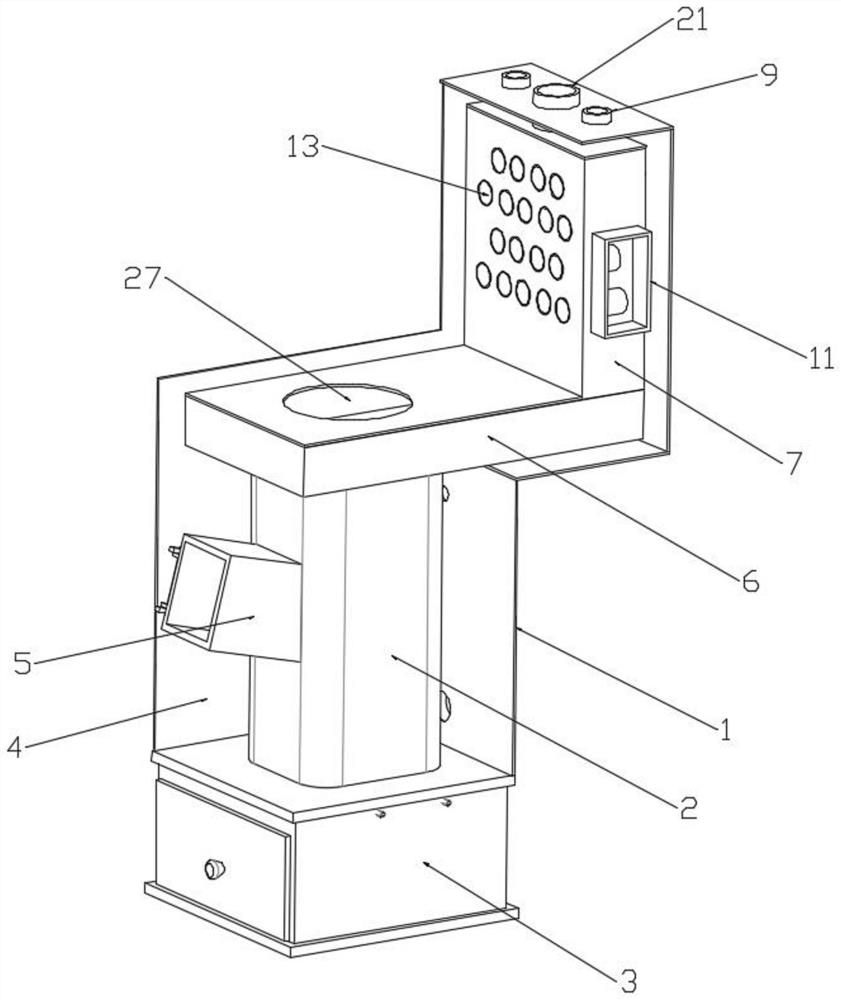

Heating stove

PendingCN112984606AEasy to useReduce usageStoves/ranges with convection heatingSolid heating fuelThermodynamicsCombustion chamber

The invention relates to the field of heating devices, in particular to a heating stove which comprises a base and a combustion chamber arranged on the upper portion of the base. A horizontal flue is arranged on the upper portion of the combustion chamber, a vertical flue is connected to the end, away from the combustion chamber, of the horizontal flue, and a stove shell is arranged outside the combustion chamber, the horizontal flue and the vertical flue in a wrapping mode; a closed cavity between the inner wall of the stove shell and the outer walls of the combustion chamber, the horizontal flue and the vertical flue is a water chamber, a stove opening is formed in the position, over an outlet of the combustion chamber, of an upper top plate of the horizontal flue, a smoke check ring is arranged between the outlet of the combustion chamber and the stove opening, a smoke outlet is formed in the side, away from the vertical flue, of the upper portion of the ring body of the smoke check ring, a water outlet pipe is arranged at the bottom of the stove shell, and a water inlet pipe is arranged at the top of the stove shell; and a layer of refractory material is attached to the inner wall of the combustion chamber, a grate bridge is arranged at the bottom of the combustion chamber, and a supporting plate used for supporting the refractory material is arranged below the combustion chamber.

Owner:曹同良

A flame-retardant explosion-proof valve

ActiveCN107503846BReduce the temperatureIncrease distanceMachines/enginesEngine componentsValve seatAirflow

The invention discloses an inflaming retarding type anti-explosion valve. The inflaming retarding type anti-explosion valve comprises a valve seat and a valve cover which is fixedly arranged on the valve seat. An inflaming retarding device is arranged between the valve seat and the valve cover. The inflaming retarding device comprises an inner flow guiding ring which is arranged inside the valve seat and an outer flow guiding ring which is arranged on the edge of the valve seat, and the surface of the inner flow guiding ring and the surface of the outer flow guiding ring are each provided with guide holes. A set of inflaming retarding rings are arranged between the inner flow guiding ring and the outer flow guiding ring. The bottom of the valve seat is provided with a valve clack, the valve clack is provided with a spring, one end of the spring presses the valve clack tightly, and the other end of the spring abuts against the valve cover. The inflaming retarding type anti-explosion valve has the beneficial effects that the anti-explosion valve can increase the paths through which gas flow and flame pass and prolong the time when the gas flow and the flame pass through multiple times of diversion, extruding and other repeating process on concentrated gas flow, meanwhile, the gas flow makes sufficient contact and exchange heat with all ring faces of the inflaming retarding rings, finally, the pressure is reduced and released, the gas flow temperature is reduced, and the flame is completely extinguished.

Owner:ZHEJIANG UNIV OF TECH

Flame-retardant explosion-proof valve for crankcase

ActiveCN107559088BSimple structureEasy to produceMachines/enginesEngine componentsCrankcaseEngineering

The invention discloses a flame-retardant type anti-explosion valve of a crankcase. The flame-retardant type anti-explosion valve of a crankcase comprises a valve deck and a valve seat. A valve clackis arranged on the valve seat. An inner flame-retardant ring group, an outer flame-retardant ring and a spring are arranged between the valve deck and the valve seat. The upper end of the spring is fixed to the valve deck. The lower end of the spring tightly presses the valve clack. The inner flame-retardant ring group and the outer flame-retardant ring are arranged in the space formed by the valve deck and the valve seat to form a flame retardant device. Because the flame-retardant type anti-explosion valve of a crankcase is adopted, the airflow through holes of the valve are evenly distributed along the surfaces of ring bodies, the airflow through holes of the same ring body are evenly arranged side by side, the airflow through holes of two adjacent ring bodies stagger to form labyrinthtype bend channels, the time for airflow and flames to pass through can be effectively prolonged while heat exchange between airflow and the inner walls of the flame retardant rings can be sufficient,the use ratio of the flame retardant rings is increased to the maximum degree, the temperature is lowered, and the purposes of reducing pressure and putting out flames are achieved finally. The flame-retardant type anti-explosion valve of a crankcase is simple in structure, and easy to produce and install. The problems exist in an anti-explosion valve can be solved. The flame-retardant type anti-explosion valve of a crankcase has broad application prospects.

Owner:ZHEJIANG UNIV OF TECH

Inflaming retarding type anti-explosion valve

ActiveCN107503846AReduce the temperatureIncrease distanceMachines/enginesEngine componentsEngineeringValve seat

The invention discloses an inflaming retarding type anti-explosion valve. The inflaming retarding type anti-explosion valve comprises a valve seat and a valve cover which is fixedly arranged on the valve seat. An inflaming retarding device is arranged between the valve seat and the valve cover. The inflaming retarding device comprises an inner flow guiding ring which is arranged inside the valve seat and an outer flow guiding ring which is arranged on the edge of the valve seat, and the surface of the inner flow guiding ring and the surface of the outer flow guiding ring are each provided with guide holes. A set of inflaming retarding rings are arranged between the inner flow guiding ring and the outer flow guiding ring. The bottom of the valve seat is provided with a valve clack, the valve clack is provided with a spring, one end of the spring presses the valve clack tightly, and the other end of the spring abuts against the valve cover. The inflaming retarding type anti-explosion valve has the beneficial effects that the anti-explosion valve can increase the paths through which gas flow and flame pass and prolong the time when the gas flow and the flame pass through multiple times of diversion, extruding and other repeating process on concentrated gas flow, meanwhile, the gas flow makes sufficient contact and exchange heat with all ring faces of the inflaming retarding rings, finally, the pressure is reduced and released, the gas flow temperature is reduced, and the flame is completely extinguished.

Owner:ZHEJIANG UNIV OF TECH

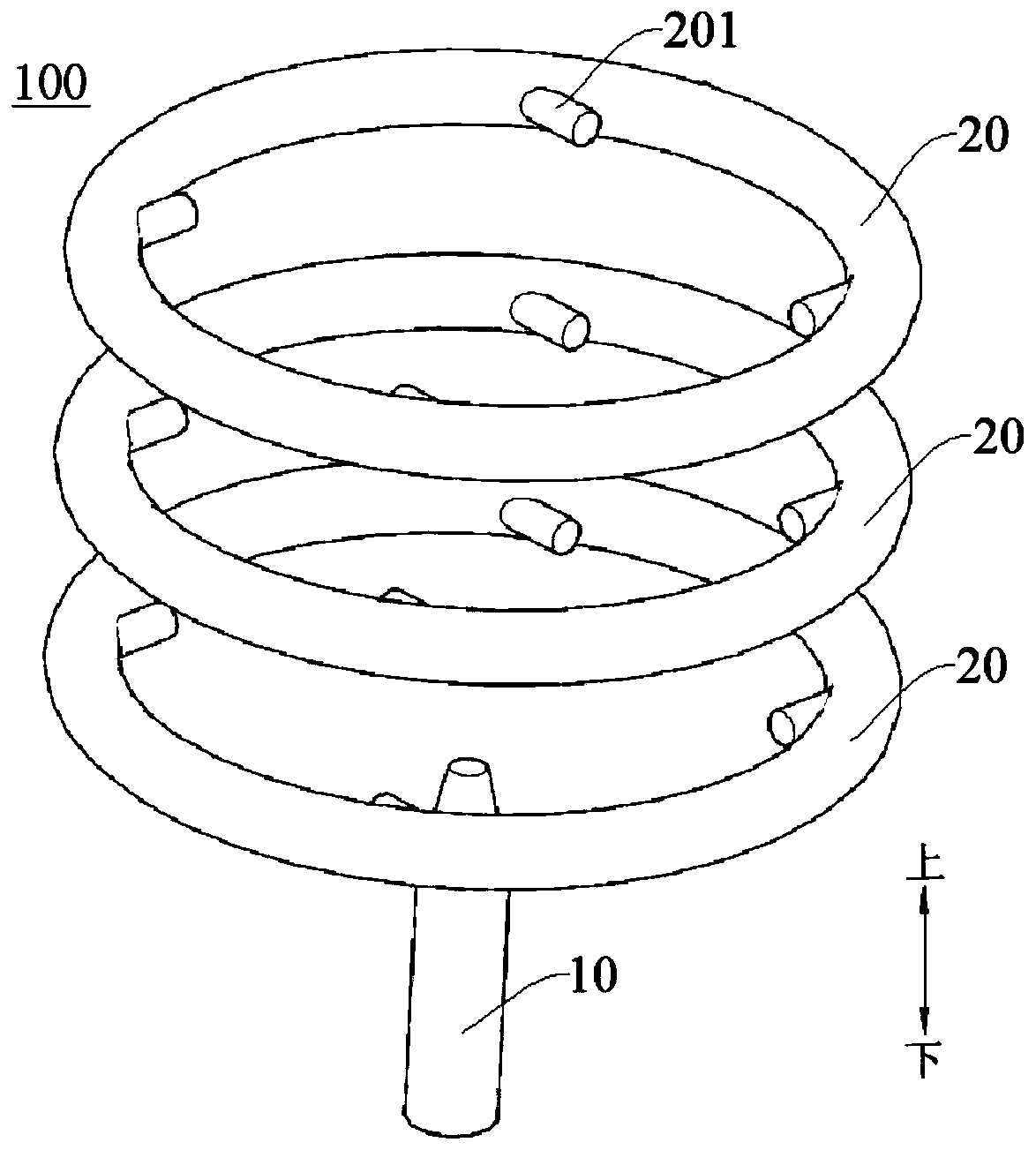

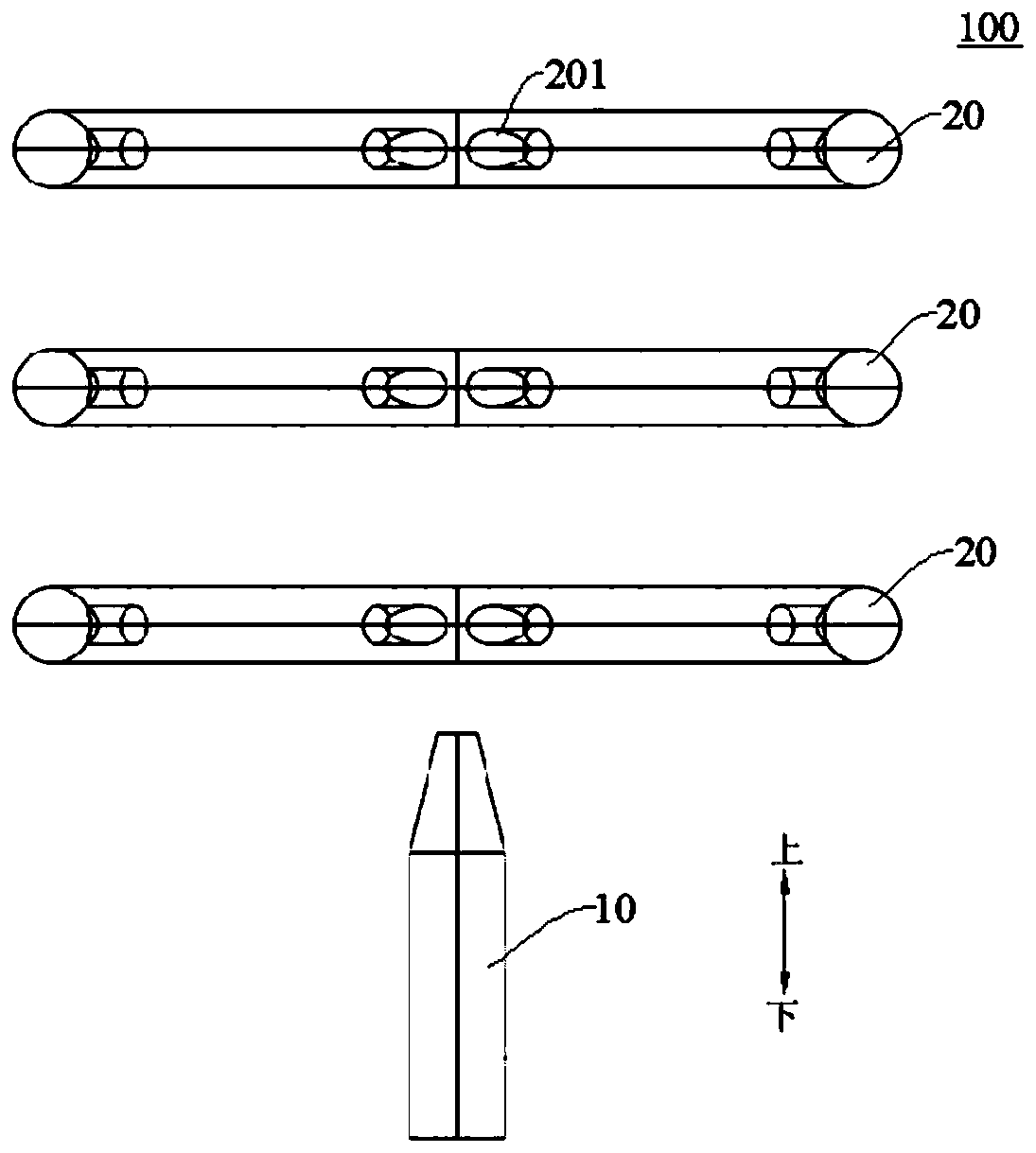

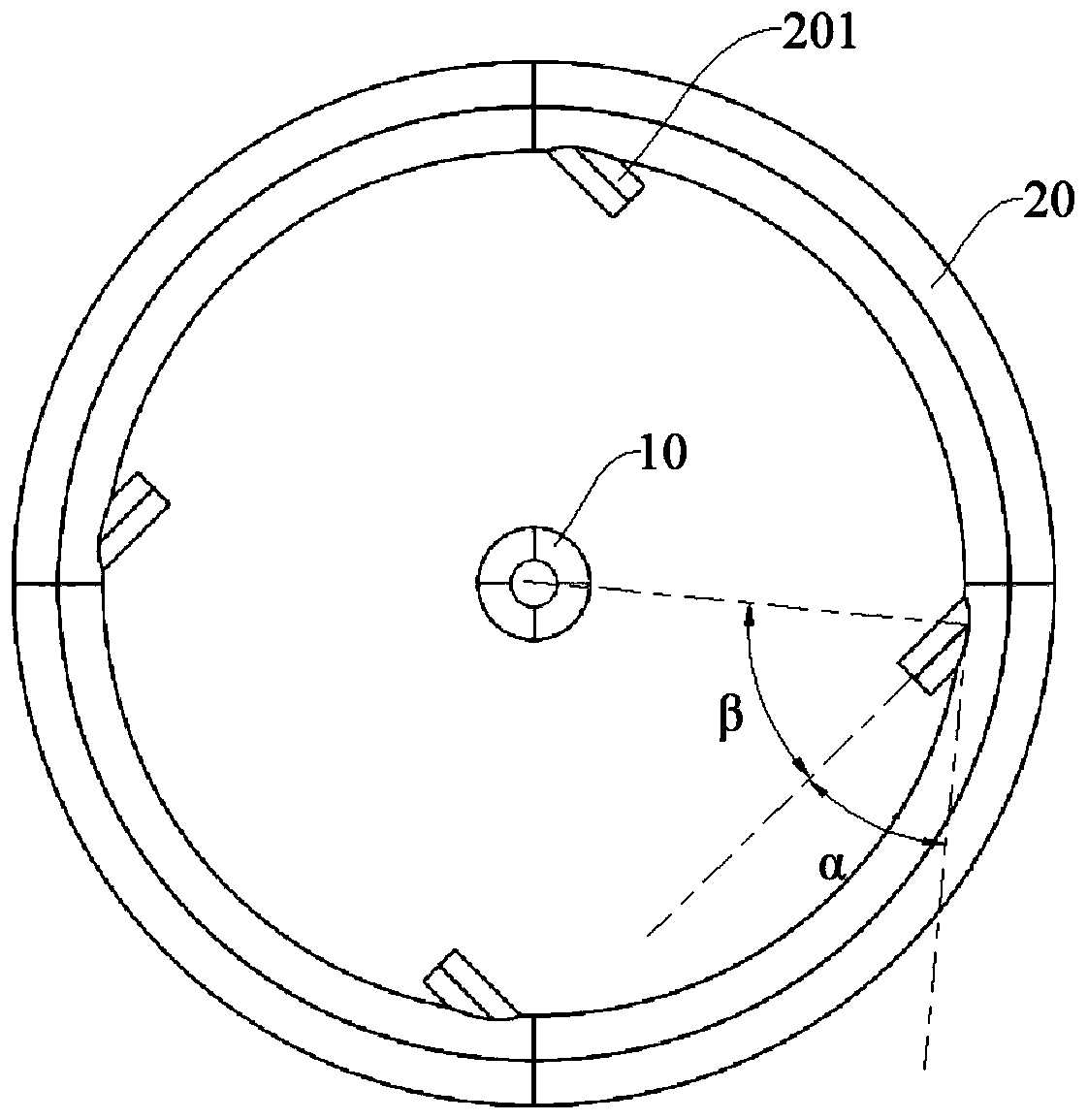

Snowfall simulation device and equipment

PendingCN111595077ASimple structureLow costRecreational ice productionLighting and heating apparatusEngineeringRefrigerant

The invention discloses a snowfall simulation device and equipment. The snowfall simulation device comprises a nozzle and heat exchangers, wherein the nozzle is used for introducing liquid and atomizing and spraying the liquid; the heat exchangers are arranged above the spraying direction of the nozzle, and the heat exchangers are closed annular tubes and provided with inlets used for introducingrefrigerants; inner rings of the heat exchangers are provided with a plurality of refrigerant spraying pipes at intervals in the circumferential direction; included angles are formed between the axesof the refrigerant spraying pipes and the inner rings of the heat exchangers; and the included angles are configured in the mode that the refrigerants sprayed by the refrigerant spraying pipes form cooling swirling flow in the centers of the heat exchangers. According to the device, the low-temperature environment can be created above the spraying direction of the nozzle, the structure is simple,a cold load under the snowfall condition in the laboratory environment can be reduced, requirements on the overall environment of a laboratory are remarkably reduced, and the cost is reduced. By meansof the low-temperature cooling swirling flow formed by the refrigerants sprayed by the refrigerant spraying pipes in the inner rings of the heat exchangers, atomized droplets can make full contact and exchange heat, and snowfall is fully developed in a small area.

Owner:HEFEI INST FOR PUBLIC SAFETY RES TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com