Tunnel insulation ditch heating system using ground source heat pump

A ground source heat pump and heating system technology, applied in drainage, safety devices, mining devices, etc., can solve problems such as threats to power supply lines, damage to tunnel structures, and poor thermal insulation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

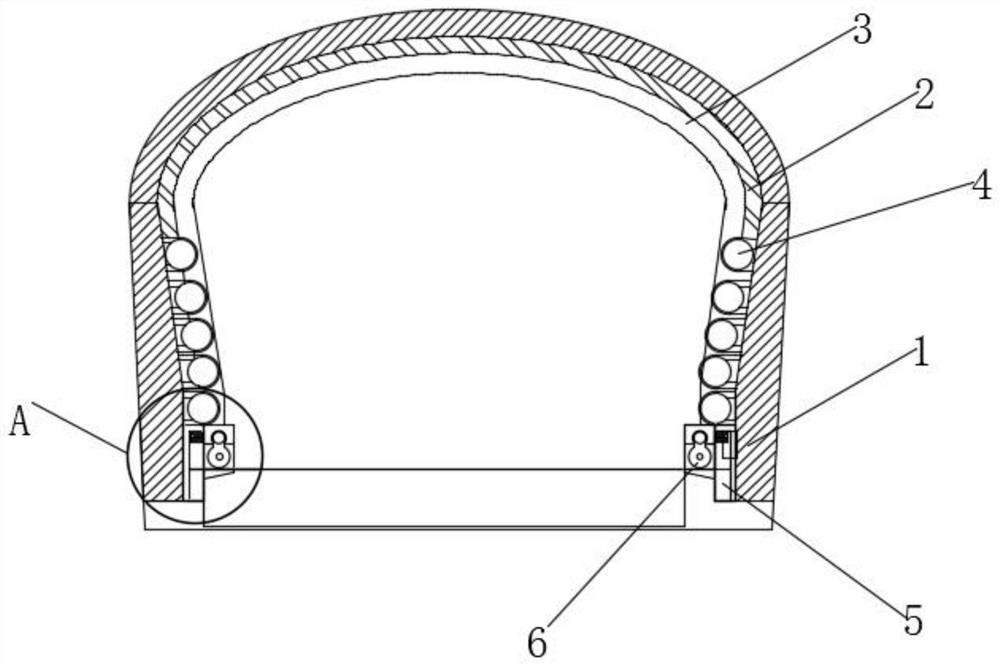

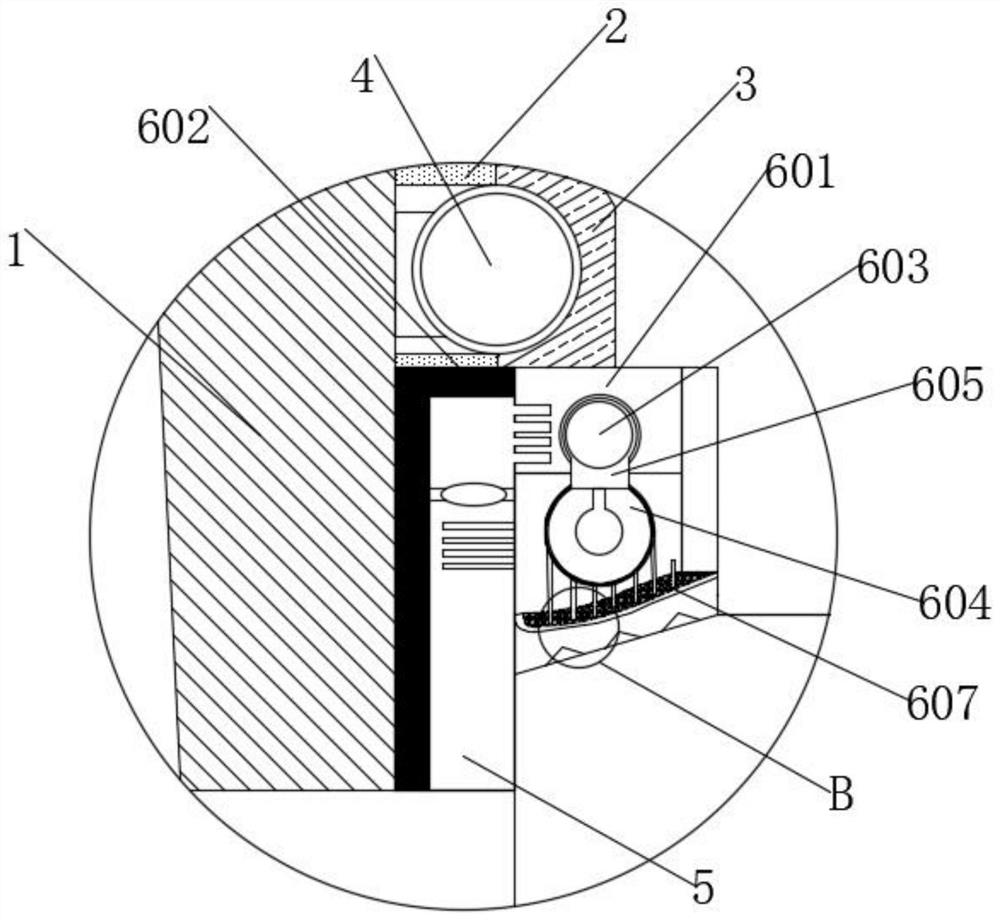

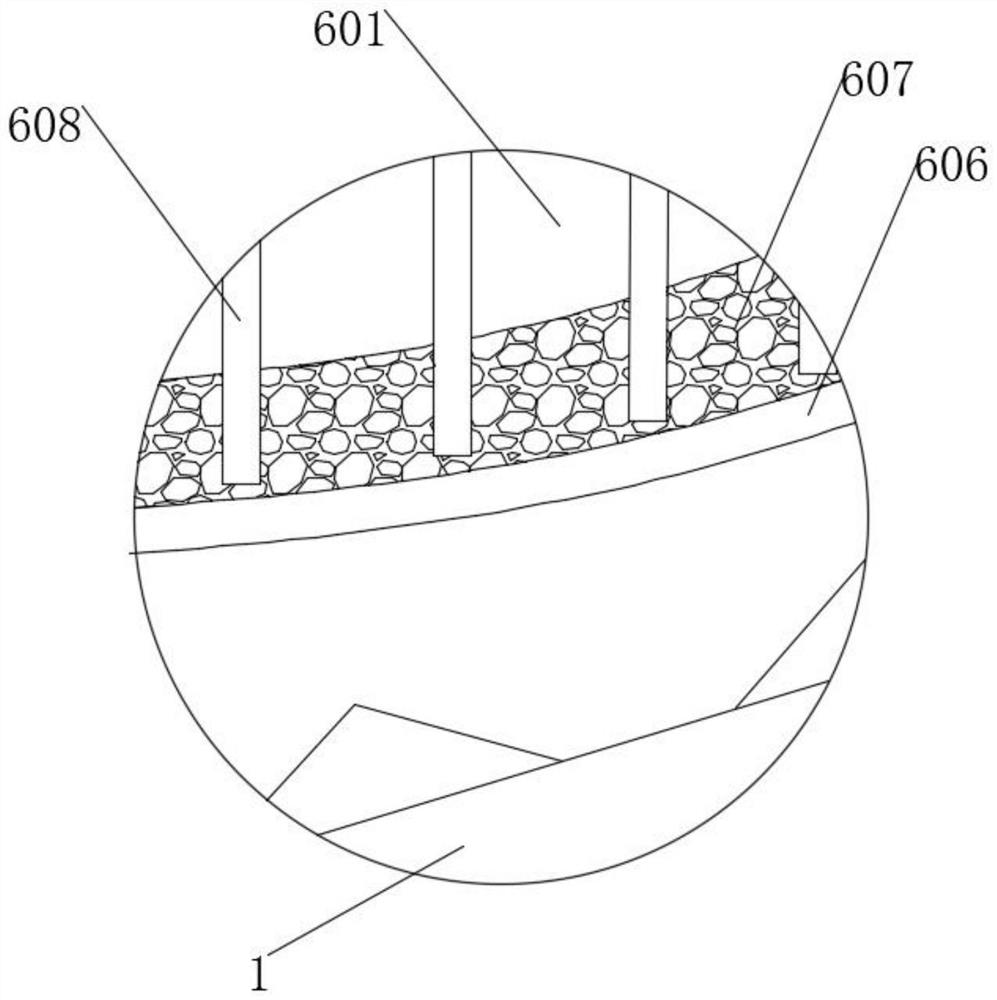

[0031] Example 1: See Figure 1-4 , a tunnel heat preservation ditch heating system for a ground source heat pump, comprising a tunnel main body 1, a pair of drains 5 are excavated at the bottom of the inner wall of the tunnel main body 1, the drains 5 are resin drains, and the depth of the drains 5 in the insulation pipe 6 is It is 30-40cm, and the insulation temperature range of drain 5 is 10-15 ℃. An insulation layer 2 is fixedly connected to the inner wall of the tunnel main body 1, and an installation layer 3 is fixedly connected to the insulation layer 2. A plurality of uniformly distributed heat exchange tubes 4 are connected between the insulation layer 2 and the installation layer 3. The main body 7 of the heat source ground pump is installed, and a plurality of heat exchange tubes 4 form a circulation pipeline. The plurality of heat exchange tubes 4 are respectively located in the front, middle and rear parts of the tunnel main body 1, and the inside of the tunnel is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com