Condenser

A technology of a condenser and a body, applied in the field of refrigeration systems, can solve the problems of large size, high cost, and low condensation efficiency of the condenser, and achieve the effects of increasing the welding area, avoiding deformation problems, and improving condensation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

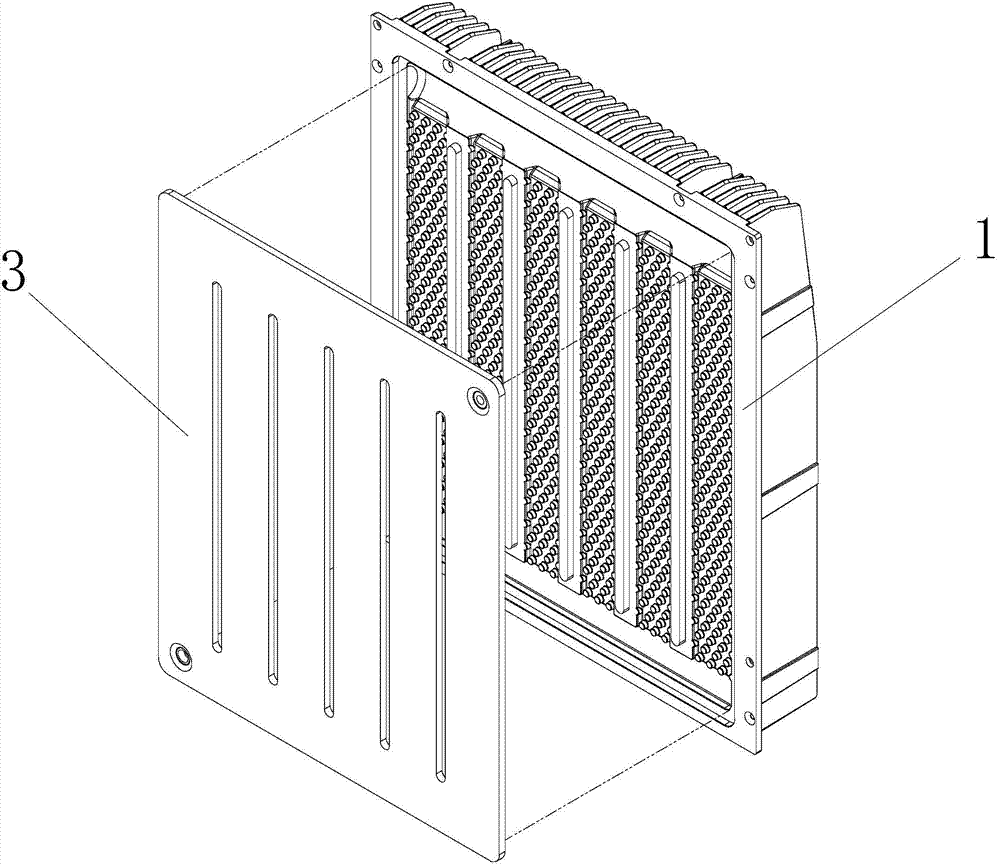

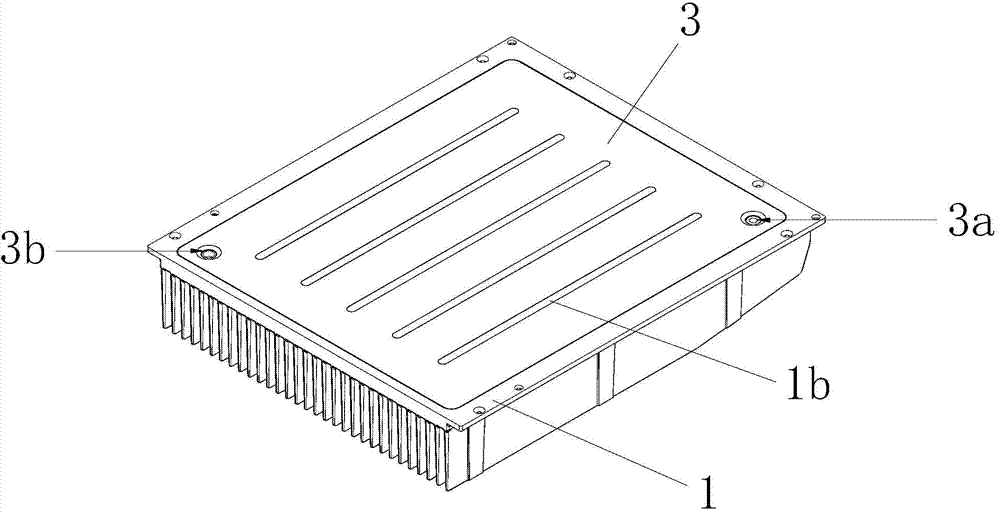

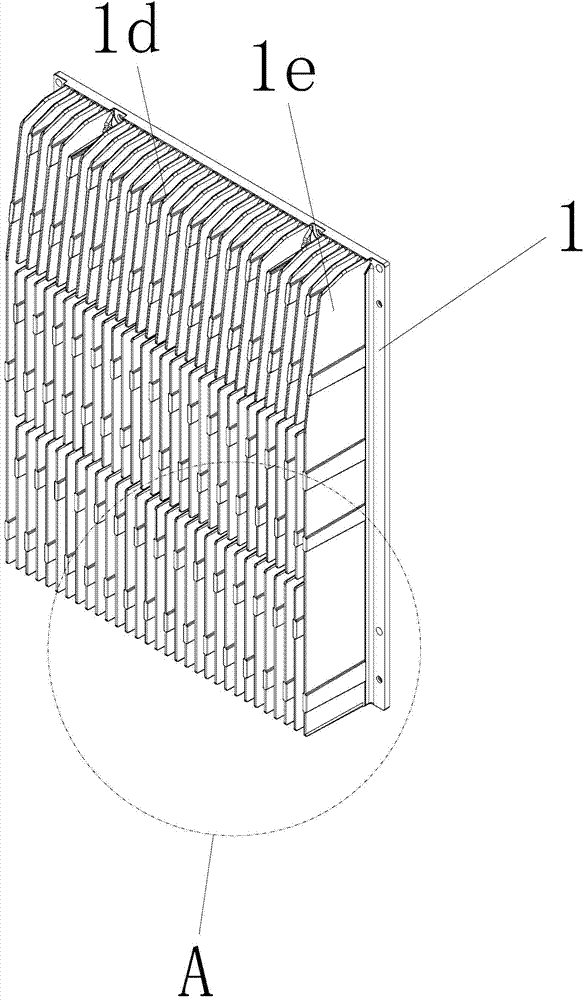

[0040] Example: Figure 1 to Figure 11A specific embodiment of the condenser of the present invention is shown, the condenser is mainly used in cabinet air conditioners, and it includes a condenser body 1 with an open cavity 2, on which the condenser body 1 is fixed and arranged A cover plate 3 at the opening of the open cavity 2 , and the cover plate 3 seals the open cavity 2 , thereby forming a closed cavity between the cover plate 3 and the condenser body 1 . The open cavity 2 is composed of a liquid inlet chamber 2a, a liquid outlet chamber 2b and a liquid outlet chamber 2c distributed sequentially from front to back. The cover plate 3 is provided with a liquid inlet hole 3a and a liquid outlet hole 3b communicating with the open cavity 2 (obviously, the liquid inlet hole 3a and the liquid outlet hole 3b are also formed by the cover plate 3 and the condenser body 1 The airtight cavity of the liquid is connected), specifically: the liquid inlet hole 3a communicates with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com