A flame-retardant explosion-proof valve

A technology of explosion-proof valves and valve seats, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems of flame retardant sheet or flame retardant deformation, pressure increase, air flow direction, etc., to increase distance and time, Release stress reduction, stress-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below with reference to the accompanying drawings.

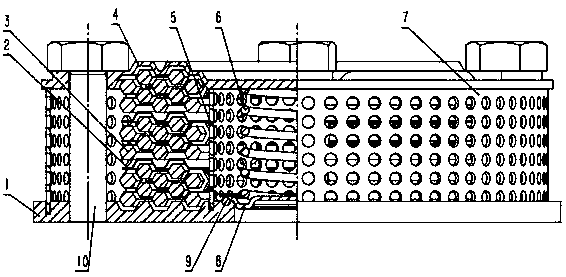

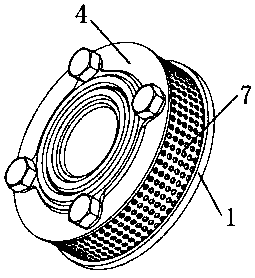

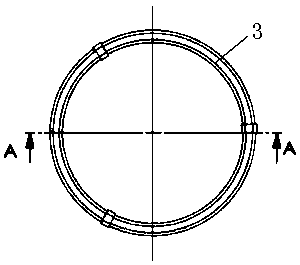

[0028] like Figure 1-12 As shown, a flame-retardant explosion-proof valve includes a valve seat 1, a baffle plate 2, a flame-retardant ring 3, a valve cover 4, an inner guide ring 5, a spring 6, an outer guide ring 7, a valve disc 8, a seal Ring 9 and bolt 10. The valve cover 4 is fixedly arranged on the valve seat 1, and a flame retardant device is arranged between the valve seat 1 and the valve cover 4. The flame retardant device includes an inner guide ring 5 arranged inside the valve seat 1 and a The outer guide ring 7, the inner guide ring 5 and the outer guide ring 7 are respectively provided with guide holes on the surface; The upper part is uniformly provided with convex shoulders along the circumferential direction. The convex shoulders adopt a straight hexagonal prism structure, and every three adjacent flame retardant rings 3 form a flame retardant ring lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com