Flame retardant ring for explosion-proof valve

A technology of explosion-proof valves and circular rings, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems of failure to consider the uneven distribution of thermal air flow layers, inability to extinguish flames, and large heat flow, etc., to achieve shape Simple, high production efficiency, and the effect of improving the flame extinguishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing of description, the present invention is described further as follows:

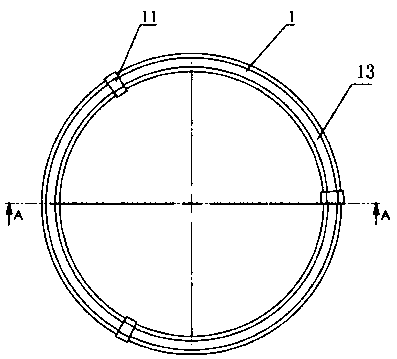

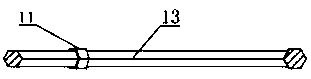

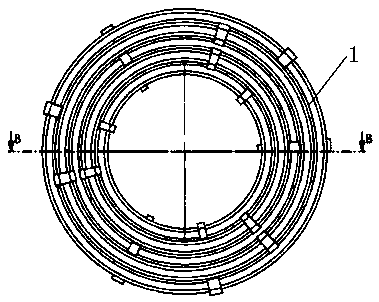

[0020] Such as Figure 1-5 As shown, a flame retardant ring of an explosion-proof valve includes a flame retardant ring 1 , a convex shoulder 11 , a Y-shaped air channel 12 and a ring member 13 . The flame retardant ring 1 includes a circular ring 13 and a convex shoulder 11 arranged on the circular ring 13. The convex shoulder 11 is evenly arranged along the circumference of the circular ring 13. Both the circular ring 13 and the convex shoulder 11 The flame retardant ring 1 is integrally molded by mold technology; the cross section of the ring member 13 adopts a regular hexagonal structure, and the convex shoulder 11 adopts a hexagonal ring structure with a regular hexagonal cross section, and the boss The center of the cross-section of the shoulder 11 is set concentrically with the center of the cross-section of the ring member 13; the radius of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com