Air cooling device

An air cooling and cooler core technology, which is applied in household refrigeration devices, lighting and heating equipment, household appliances, etc., can solve the problems of affecting the service life of the equipment, the weight of the cooler core, and the inconvenience of installation and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the invention are described in detail below, but the invention can be practiced in many different ways as defined and covered by the claims.

[0025] High-pressure air cooling technology is an important cooling technology in the fields of electric power, petroleum industry and customs. Usually, the air cooling device is a vertical cylinder structure, and the cooler core is inserted and installed in the middle of the cylinder horizontally. Water) contacts heat exchange, and the cooled air is discharged from the outlet at the bottom of the cylinder.

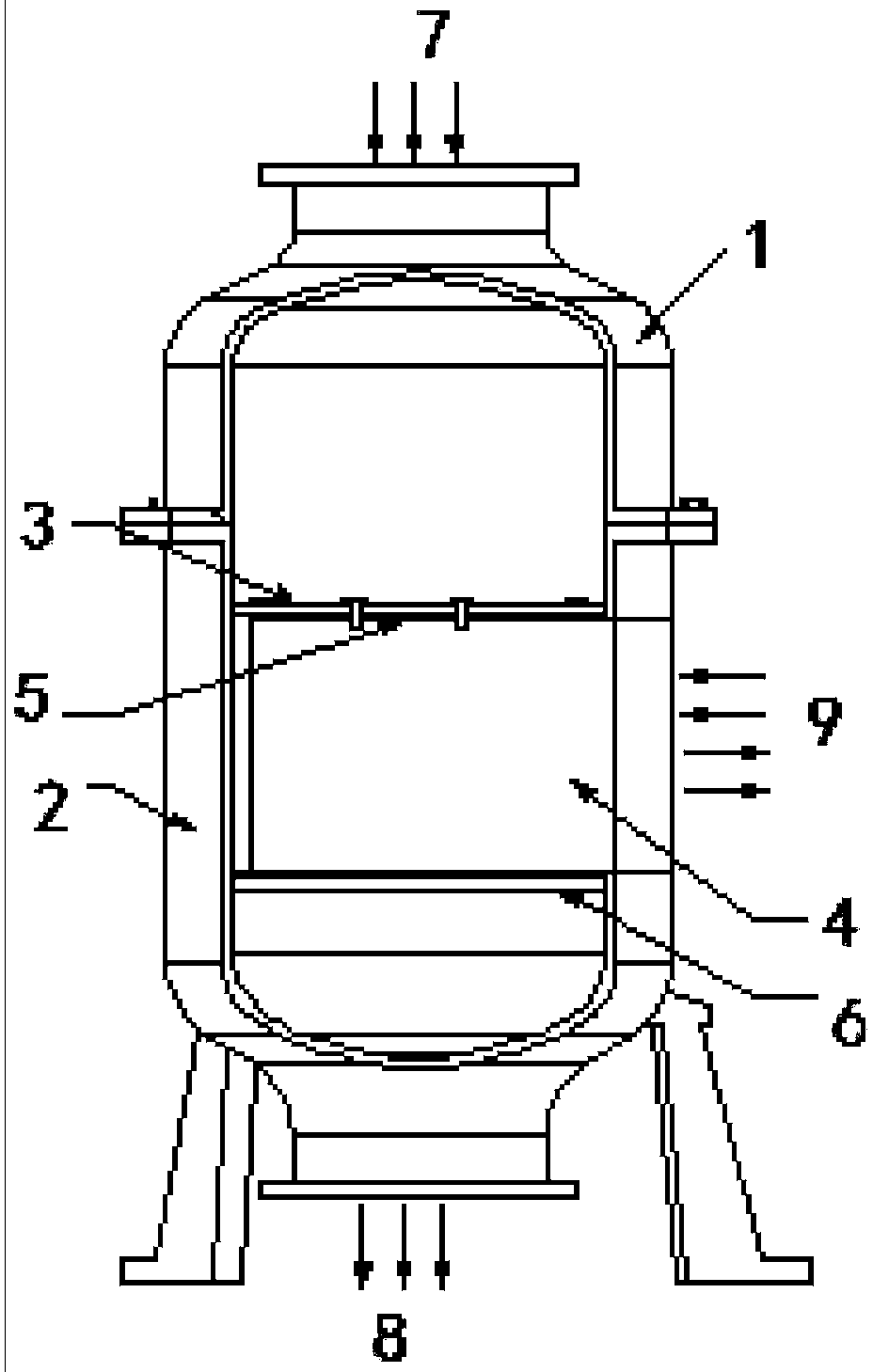

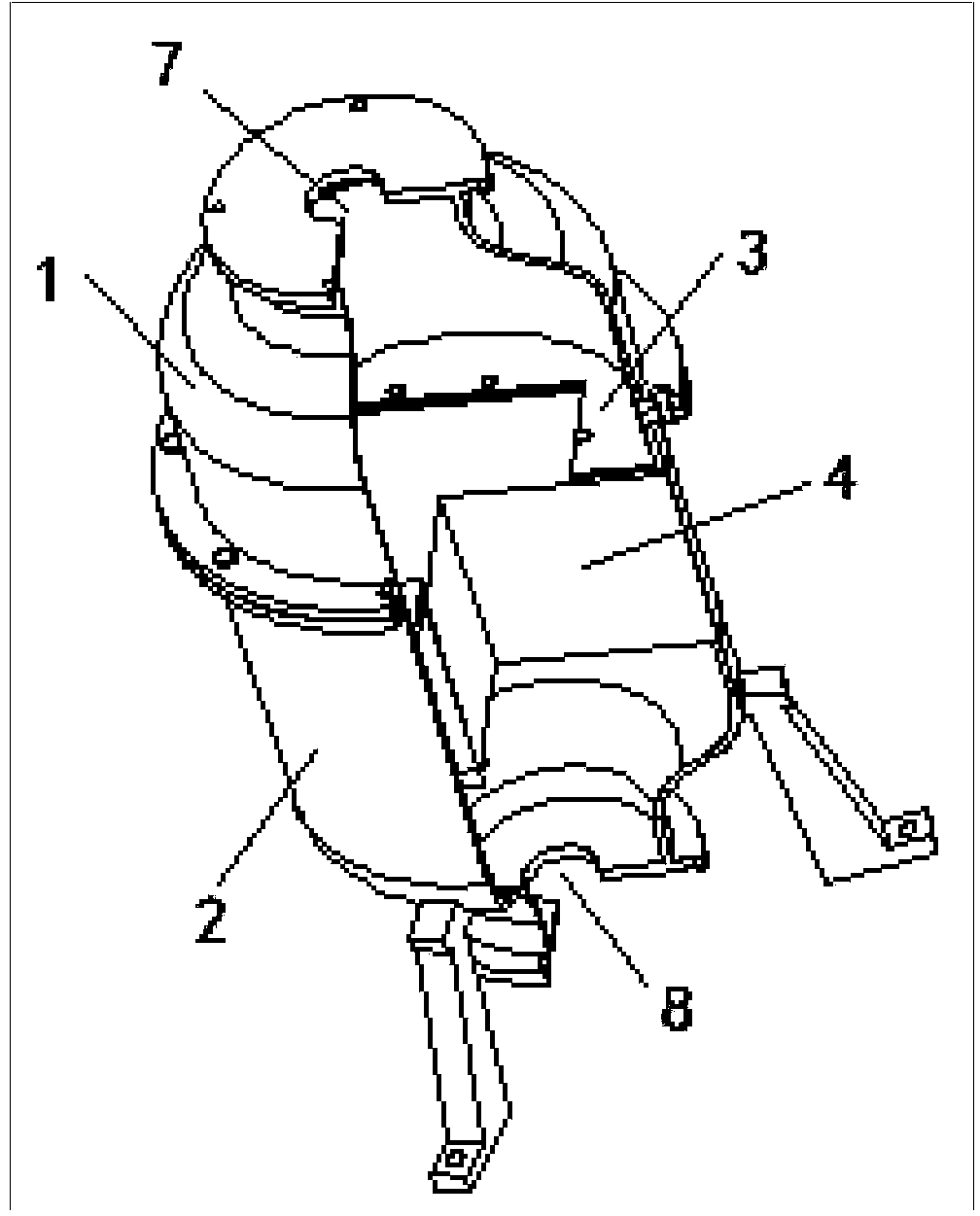

[0026] In order to solve the technical problems in the prior art, please refer to Figure 1 to Figure 2 , the present invention provides an air cooling device, comprising: an upper cylinder body 1; a lower cylinder body 2 connected to the lower cylinder body 2, an accommodation cavity is formed between the lower cylinder body 2 and the lower cylinder body 2; a first sealing steel plate 3 , installed in the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com