Integrated particle fluidized carbon dioxide capture method and device for power plant

A carbon dioxide, particle fluidization technology, applied in chemical instruments and methods, separation methods, gas treatment and other directions, can solve problems such as industries that do not widely use large energy consumption, and achieve the advantages of absorption and desorption, convenient transformation and installation, small loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below using the accompanying drawings and embodiments.

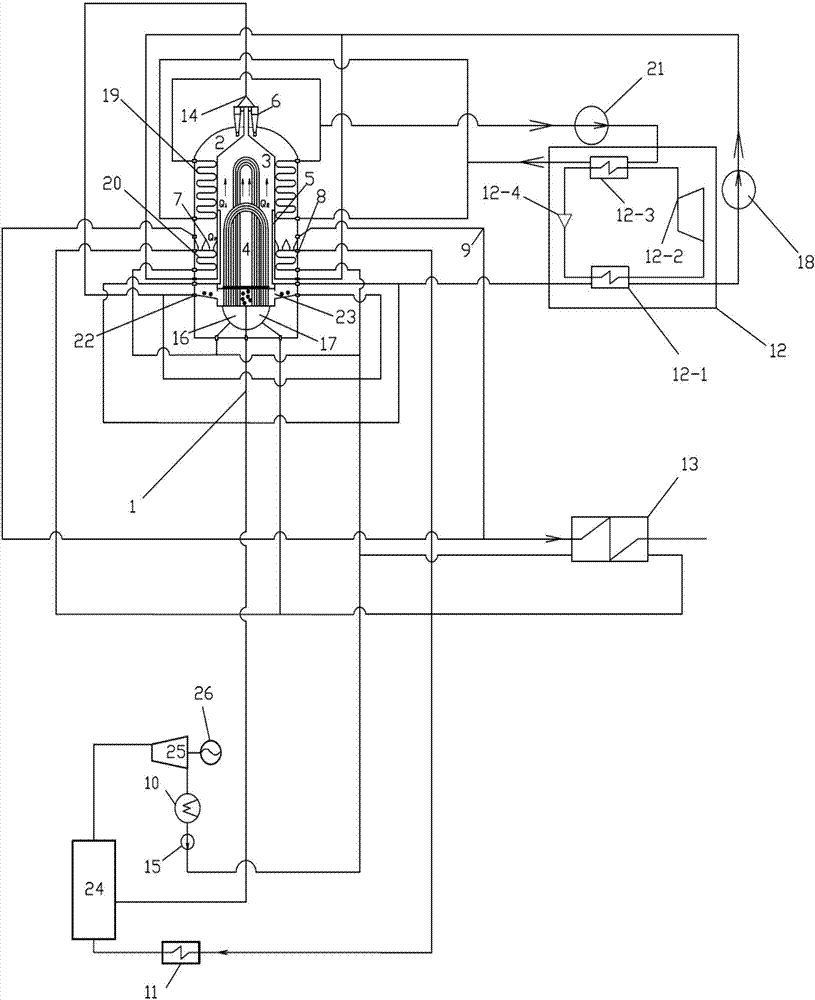

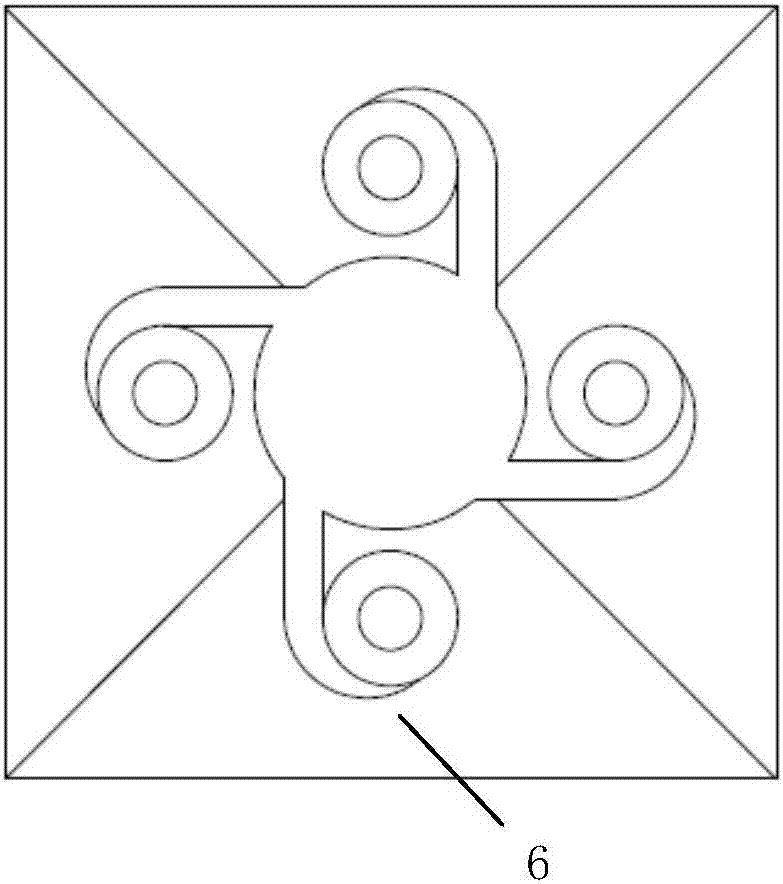

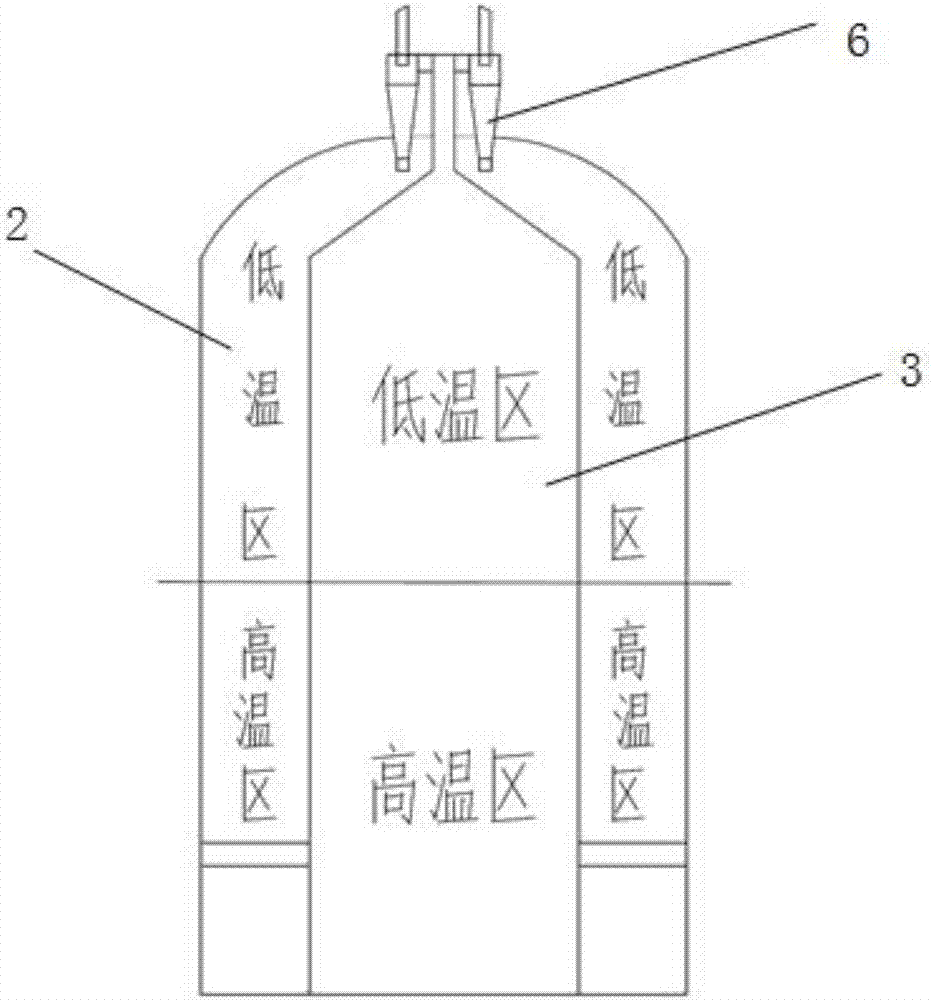

[0037] Such as Figure 1-Figure 5 , an integrated particle fluidized carbon dioxide capture device used in power plants according to the present invention takes carbon dioxide capture as the main task, and at the same time takes into account energy saving and emission reduction in the process, and maximizes the use of available heat energy. Its structure comprises: adsorption tower 3, cyclone separator 6, desorption tower 2, heat pump 12 and particle cooling zone 8; Described adsorption tower 3 is placed in desorption tower 2, and cyclone separator 6 is arranged on the top of adsorption tower 3; The adsorption tower 3 is connected to the desorption tower 2 through a cyclone separator 6; an inverted U-shaped tube heat exchanger 4 and a wall-mounted heat exchanger are placed between the bottom flue gas inlet 1 and the top flue gas outlet 14 in the adsorption tower 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com