Heat exchange tube bundle positioning net for flue gas heat exchanger with fluorine plastic heat exchange tubes

A technology of flue gas heat exchanger and heat exchange tube bundle, which is applied in the direction of heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc. Effects of contact heat transfer, increased service life and operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

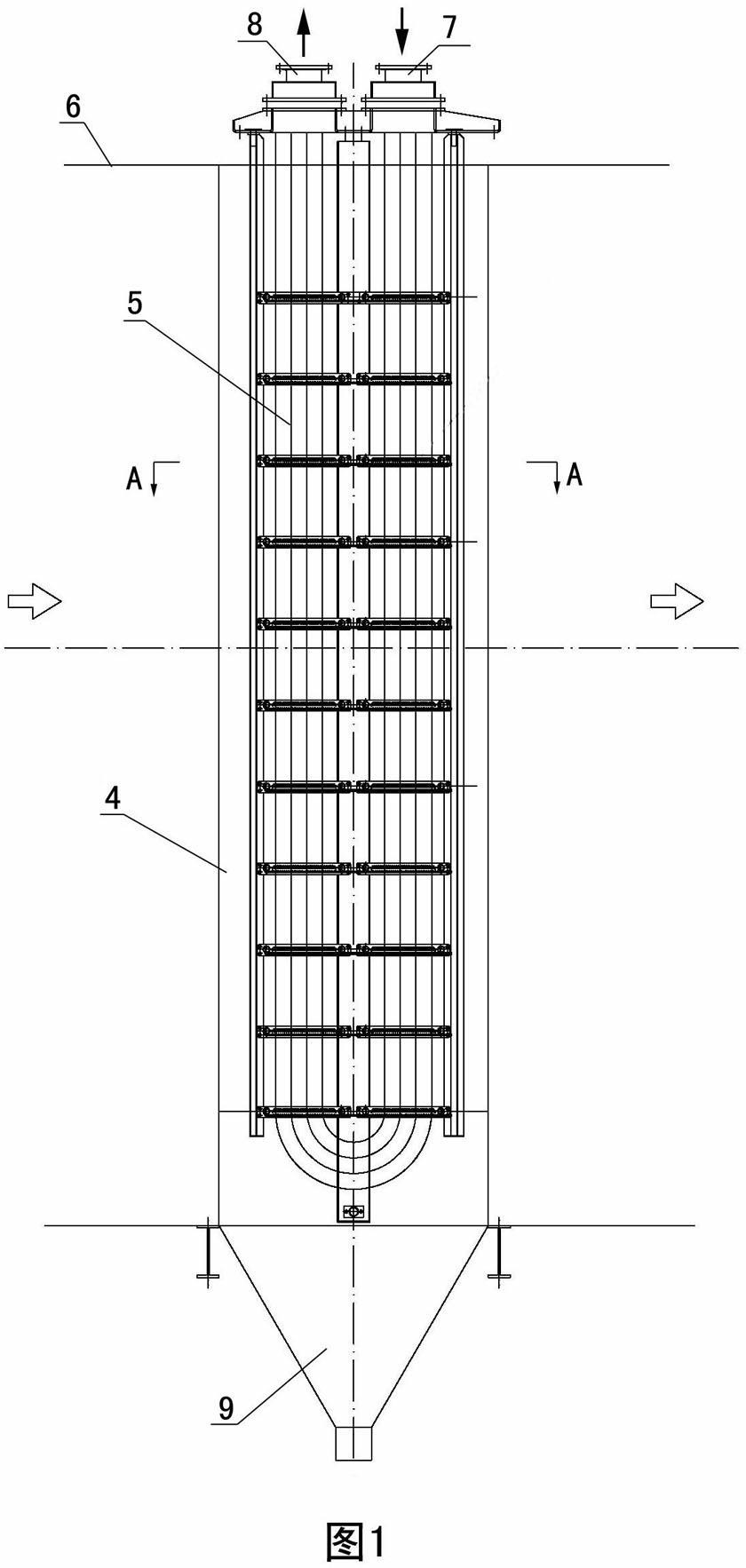

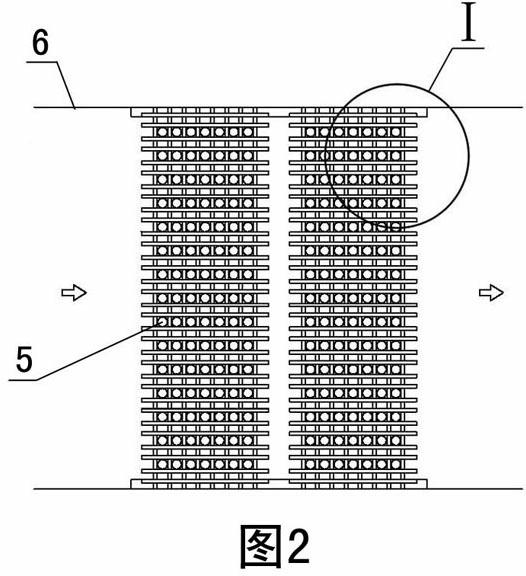

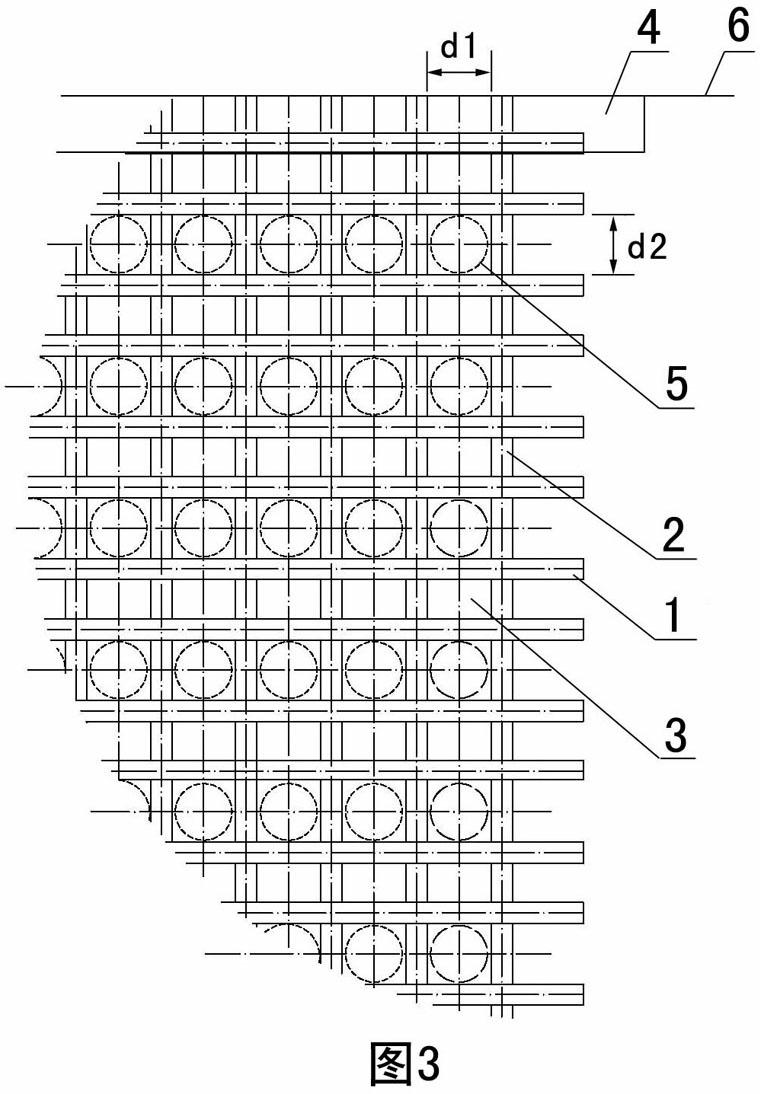

[0017] Examples see Figure 1-Figure 3 As shown, the heat exchange tube bundle positioning net used for the flue gas heat exchanger of the fluoroplastic heat exchange tube is characterized in that the positioning net is formed by interweaving the parallel positioning net latitude line 1 and the parallel positioning net warp line 2 The positioning net is made of rigid high-temperature-resistant and corrosion-resistant material, the mesh surface of the positioning net is perpendicular to the axis of the heat exchange tube bundle, and the size of the positioning net mesh 3 is adapted to the diameter of the fluoroplastic heat exchange tube 5. The periphery of the positioning net extends to the inner wall of the shell 4 of the flue gas heat exchanger.

[0018] The positioning nets are distributed at intervals along the heat exchange tube bundle. The heat exchange tube bundle positioning net used for the flue gas heat exchanger of the fluoroplastic heat exchange tube can be set onl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com