A horizontally placed fluoroplastic tubular heat exchanger

A tubular heat exchanger, horizontally placed technology, applied in the direction of heat exchanger types, indirect heat exchangers, tubular elements, etc., can solve the problem of affecting the heat exchange effect between flue gas and the medium in the tube, and the difficulty of fluoroplastic tube heat exchangers To avoid problems such as increased height, avoid vertical hoisting process, prevent shaking and deformation, and prolong life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

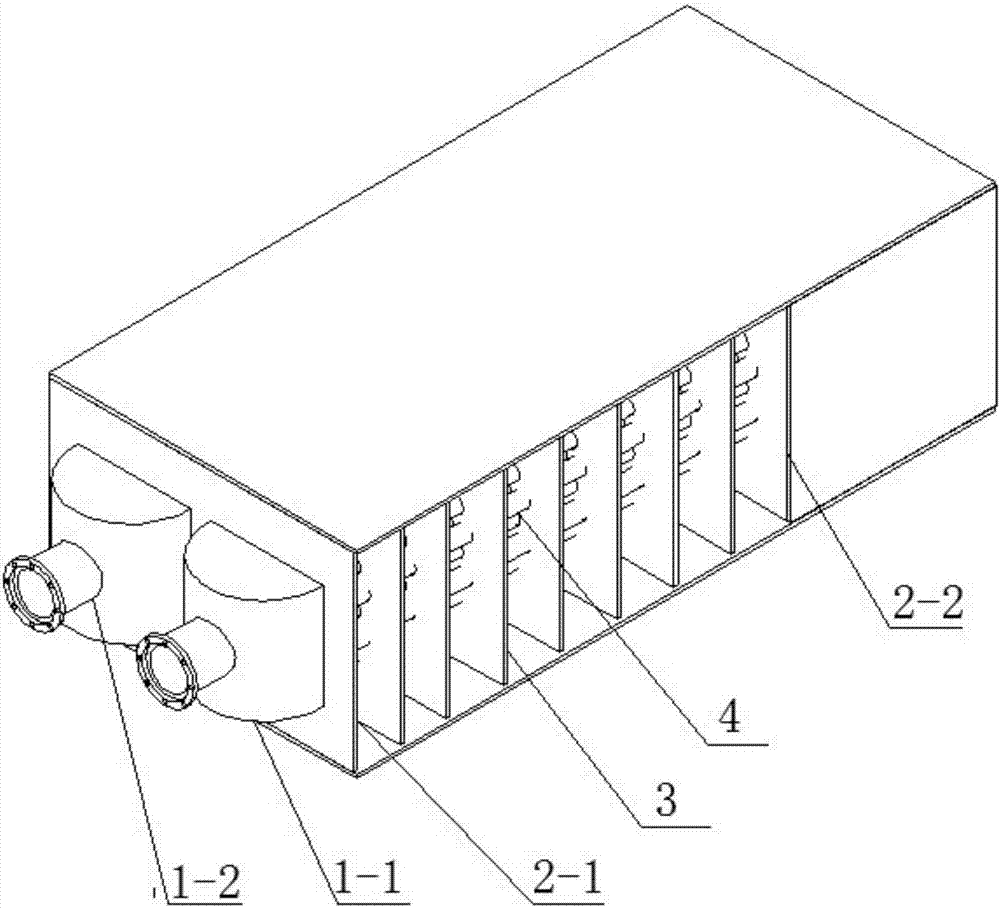

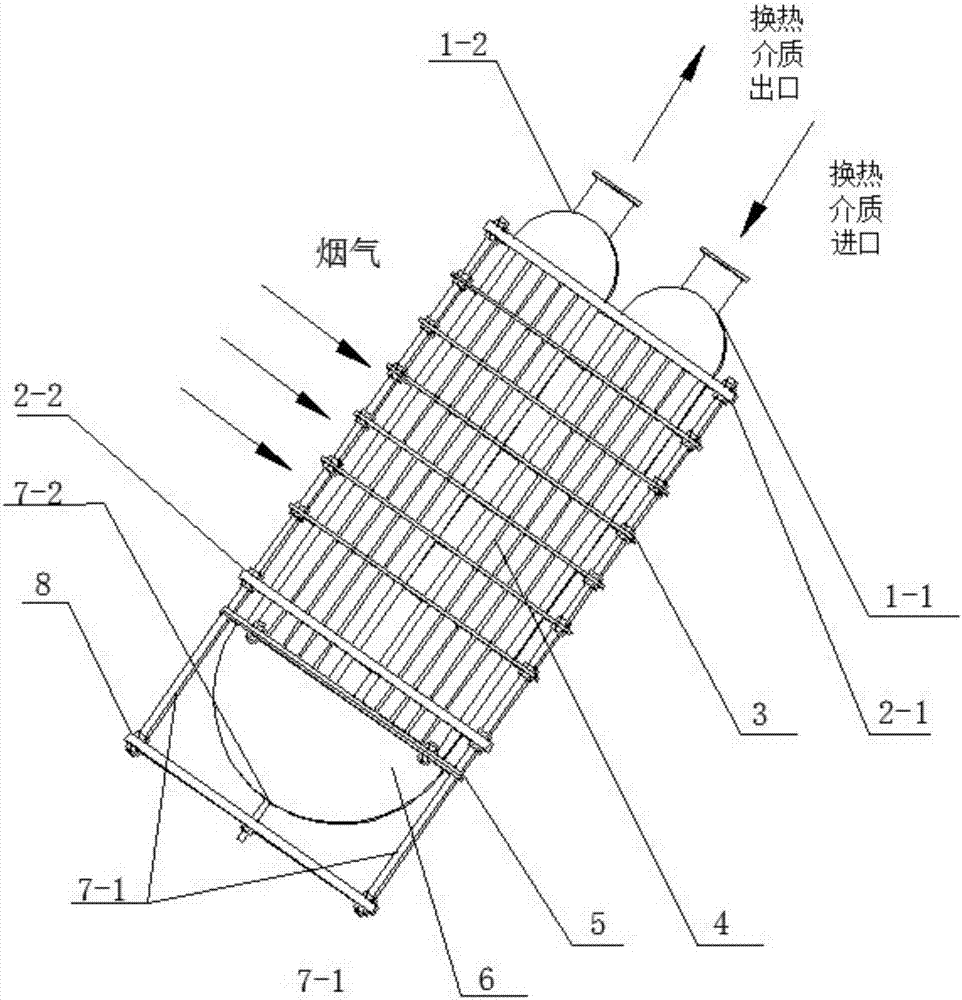

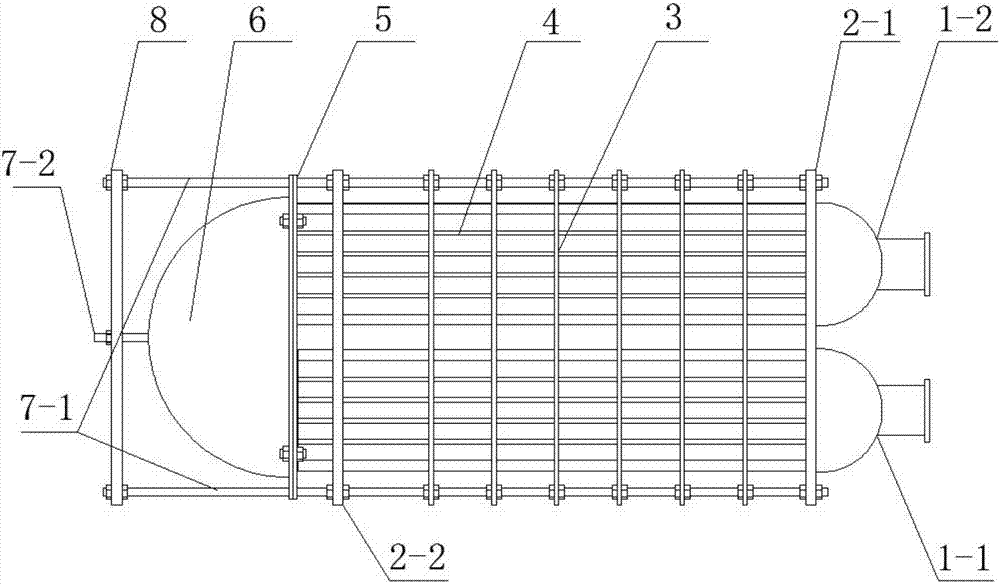

[0031] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, in this embodiment, a horizontally placed fluoroplastic tubular heat exchanger adopts straight tube bundles, including an inlet water chamber 1-1, an outlet water chamber 1-2, a front fixed tube plate 2-1, and a fluoroplastic straight tube heat exchanger. Tube bundle 4, positioning orifice plate 3, rear fixed tube plate 2-2, movable tube plate 5, movable water chamber 6, short bolt 7-2, long bolt 7-1 and fixed plate 8. The inlet water chamber 1-1 and the outlet water chamber 1-2 are arranged side by side. The fluoroplastic straight tubes in the fluoroplastic straight tube bundle 4 are arranged in a staggered arrangement, one end is expanded and connected to the front fixed tube sheet 2-1, and the other end is expanded and connected to the movable tube sheet 5. The front fixed tube plate 2-1, the positioning hole plate 3, the rear fixed tube plate 2-2, the movable tube plate 5 and the fixed plate 8 are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com