Flexible auxiliary tool

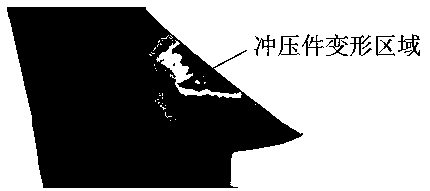

An auxiliary tooling and flexible technology, applied in the direction of feeding device, manufacturing tool, positioning device, etc., can solve the problems of large drop, deformation of stamping parts, etc., achieve the effect of strong versatility and avoid vibration deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

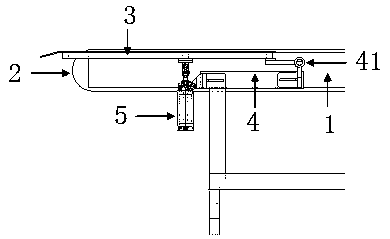

[0018] Below with reference to the accompanying drawings, through the description of the implementation examples, the specific embodiments of the present invention, such as the shape, structure, mutual position and connection relationship between each part, the role and working principle of each part, etc., will be further described. detailed description of the .

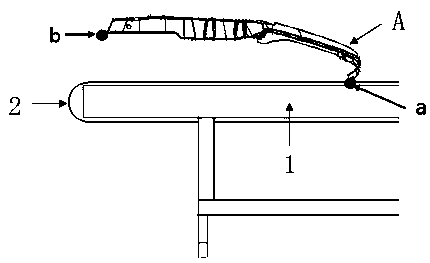

[0019] Such as Figure 3-5 , The flexible auxiliary tooling of the present invention includes a wire tail conveying platform 1, a conveyor belt 2 is provided on the wire tail conveying platform 1, and a material receiving plate 3 with an adjustable inclination is provided on the conveyor belt 2.

[0020] In the flexible auxiliary tooling of the present invention, an adjustable inclination receiving plate 3 is provided on the conveyor belt 2 of the end-of-line conveying platform 1. Before the stamping part A with a large drop is produced, the inclination of the receiving plate 3 is small or even close to At zero, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com