Plate ice machine with single-plate evaporator and operation method of plate ice machine

An evaporator and plate ice machine technology, applied in the field of machinery, can solve the problems of waste of refrigerant cooling capacity, low refrigerant heat exchange efficiency, poor plate ice thickness, etc., to enhance the heat exchange effect, extend the length of the flow path, The effect of prolonging the residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

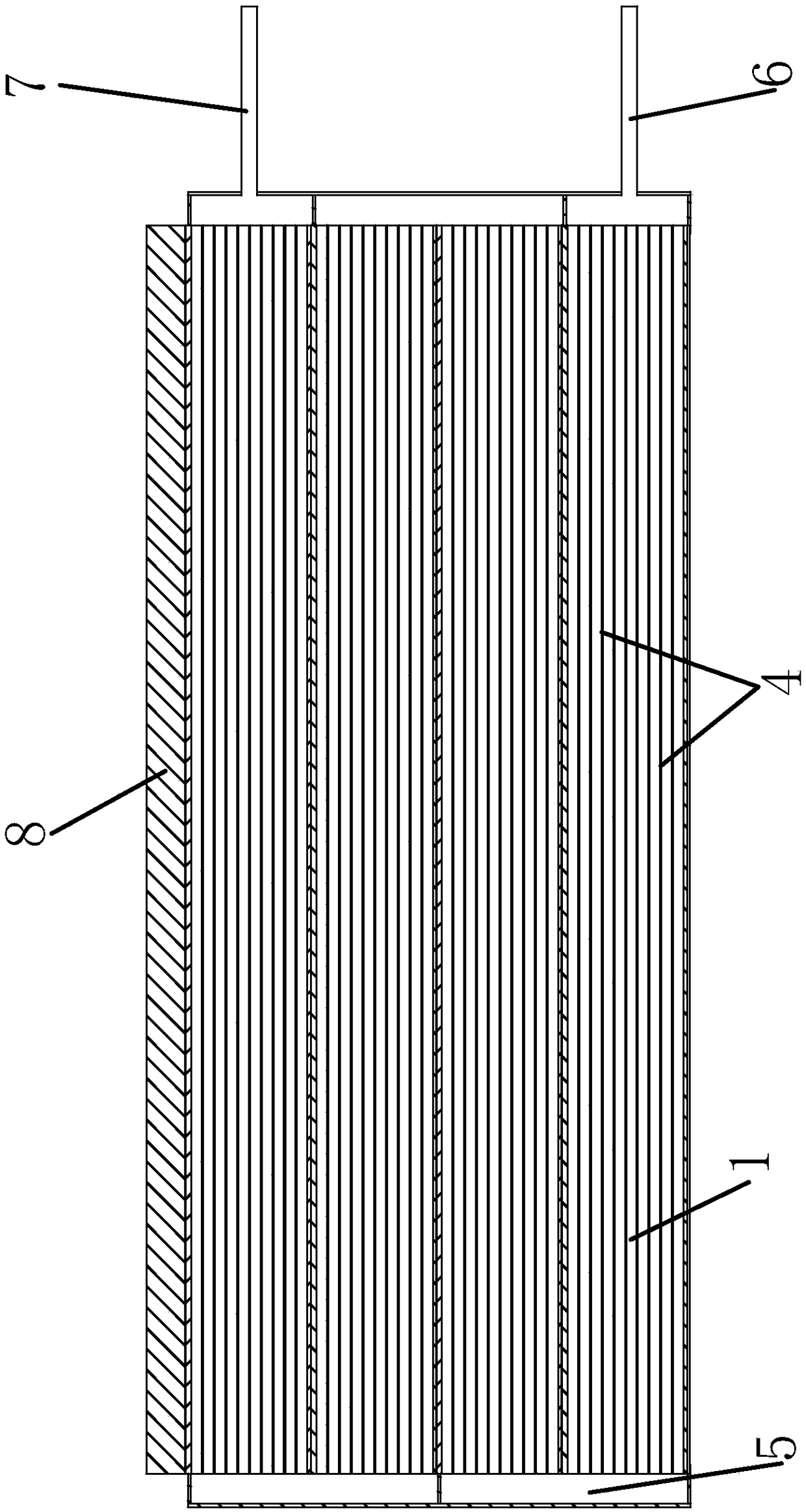

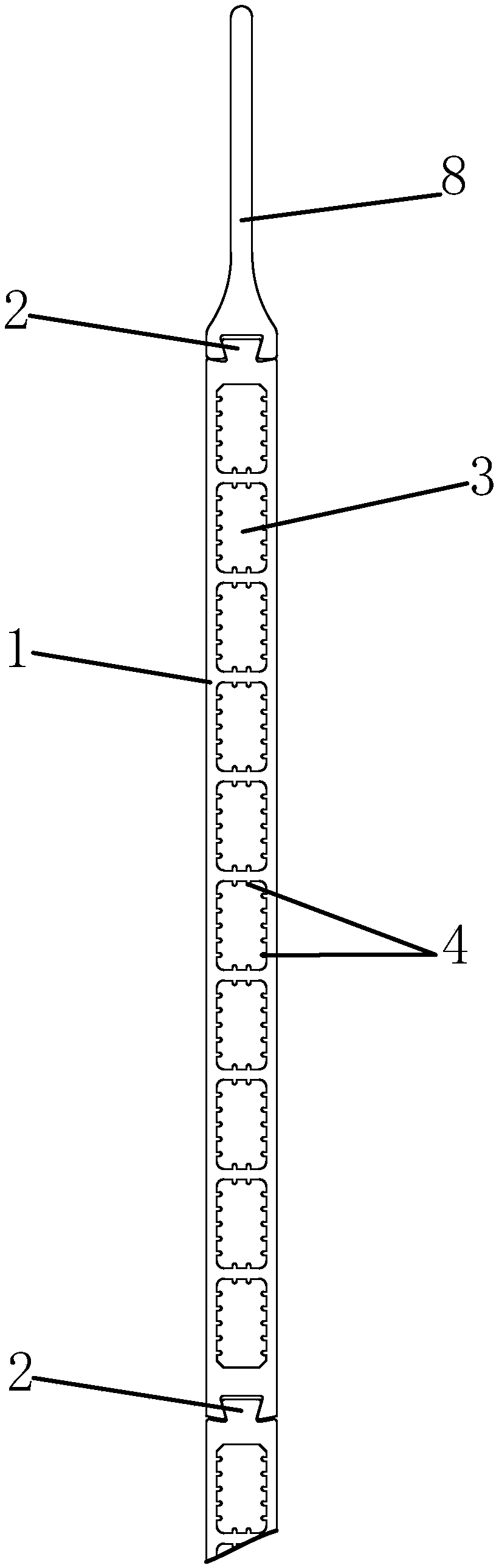

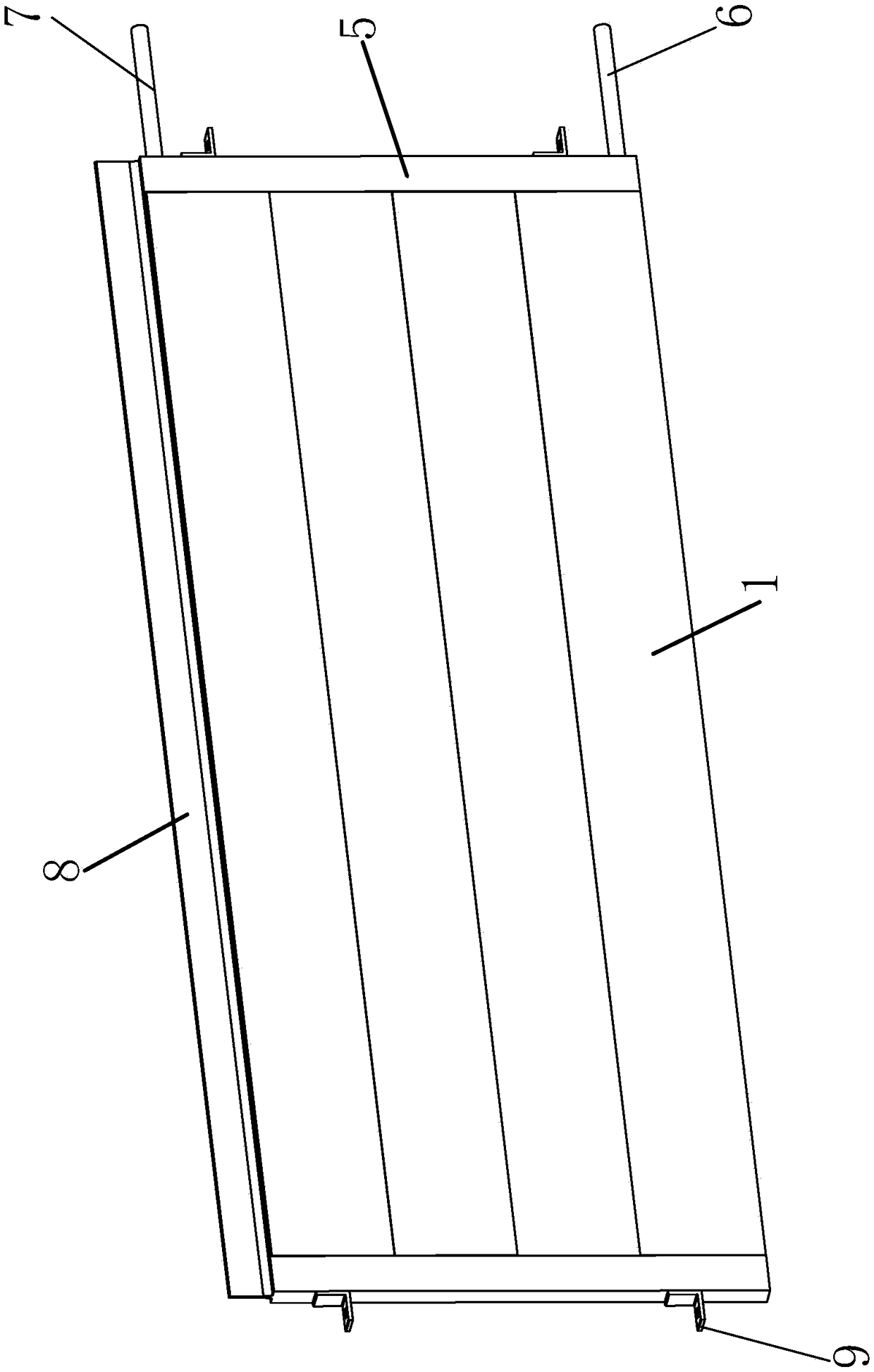

[0035] Such as Figure 1 to Figure 6As shown, the plate ice machine with a single-plate evaporator includes a fuselage shell 10, and a refrigeration system and a water delivery system are arranged in the fuselage shell 10. The refrigeration system includes a compressor connected in a loop, a condenser 20, an expansion valve and The evaporator and the water delivery system include a circulating water tank 14 connected in circulation, a water pump 15, a water supply pipe 16 and a sprinkler tank 17, and an inspection port 11 and an ice outlet 12 are set on the front of the fuselage shell 10, and the evaporator includes a parallel arrangement of Several evaporation veneers 18, the evaporation veneers 18 include several unit pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com