Air uniformizing and dust removing device for sludge drying equipment and sludge drying equipment

A dust removal device and sludge drying technology, which is applied in the direction of combined devices, dehydration/drying/concentrated sludge treatment, chemical instruments and methods, etc., can solve the problems of poor dust removal effect, large dust, evaporation and dehydration of oven sludge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

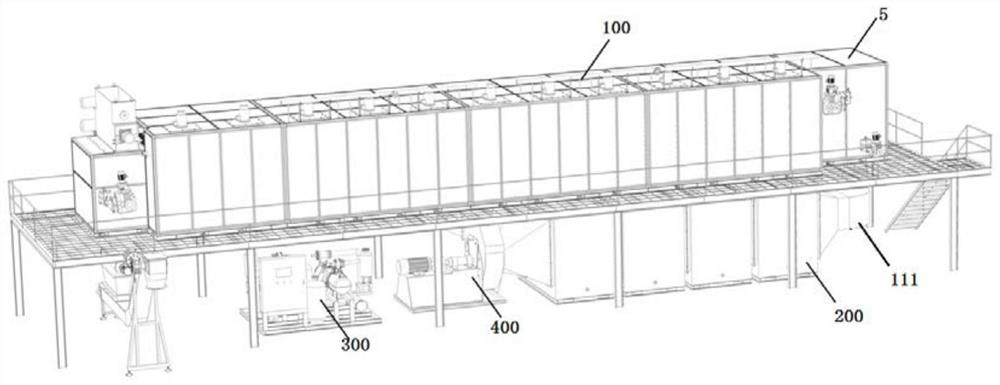

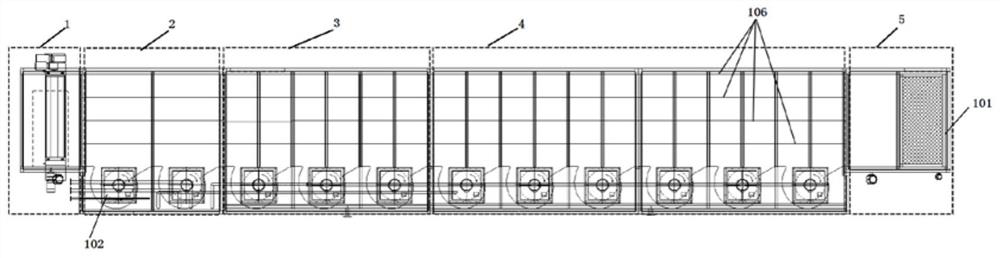

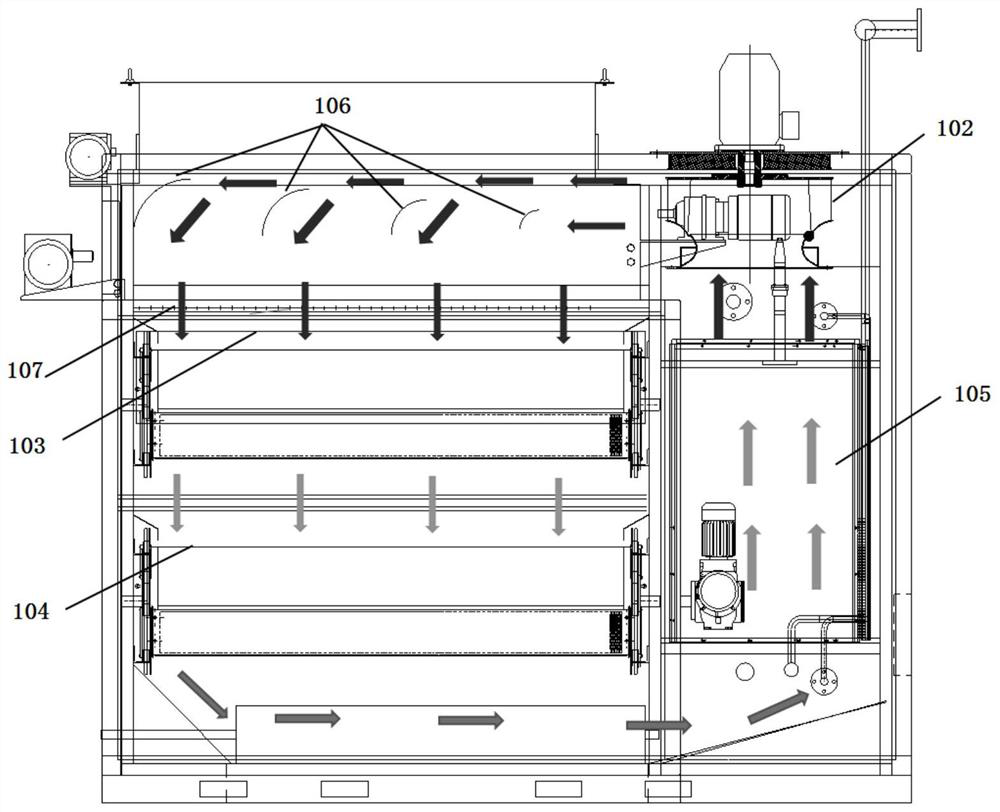

[0028] An embodiment of the present invention provides a uniform air dust removal device for sludge drying equipment, such as Figure 1-Figure 6 As shown, the air uniform dust removal device includes an oven 100, an external circulation air fan 400, a heat exchange skid 200 and a dust removal system; the oven, the external circulation air fan, and the heat exchange skid are connected to form an external circulation air channel ; The oven is provided with a transmission mesh belt and an internal circulating air channel; the upper end of the internal circulating air channel is provided with a plurality of deflectors 106, and the plurality of deflectors are used to displace the internal air in the internal circulating air channel. The circulating air is guided to the transmission mesh belt; an air equalizing plate 107 is arranged between the deflector and the transmission mesh belt; the oven and the heat exchange skid are connected through an external circulation air return channe...

Embodiment 2

[0047] An embodiment of the present invention provides a sludge drying equipment, the sludge drying equipment includes the wind uniform dust removal device as described in any one of the first embodiment.

[0048] The embodiment of the present invention can refer to Embodiment 1 during the specific implementation process, and has corresponding technical effects.

[0049] The serial numbers of the above embodiments of the present invention are for description only, and do not represent the advantages and disadvantages of the embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com