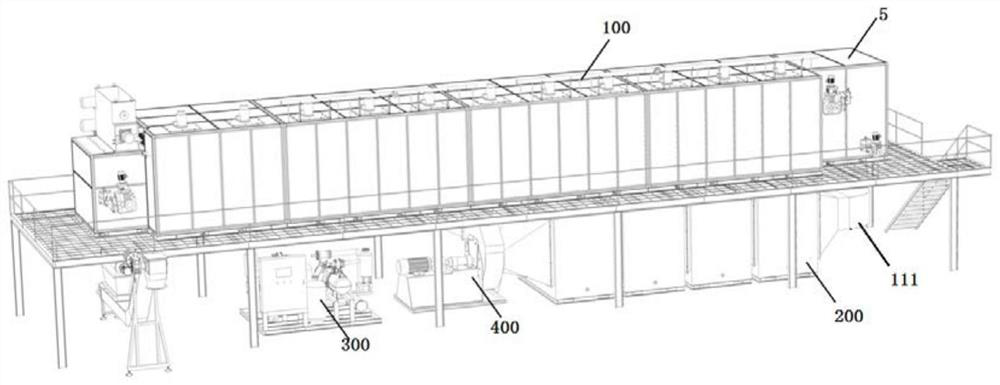

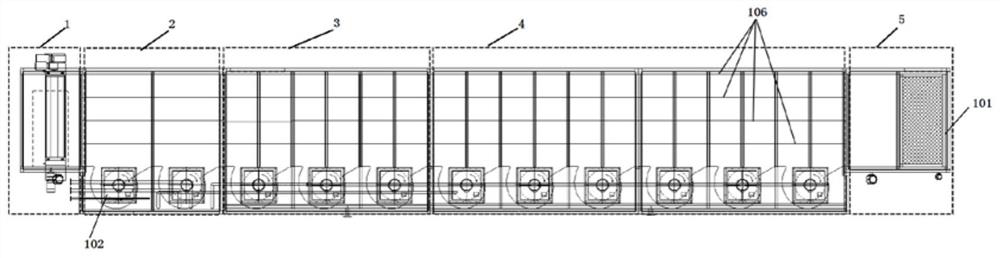

A uniform air dust removal device and sludge drying equipment for sludge drying equipment

A dust removal device and sludge drying technology, which is applied in the direction of combined devices, dehydration/drying/concentrated sludge treatment, chemical instruments and methods, etc., can solve the problems of large dust, high labor intensity, evaporation and dehydration of oven sludge, etc. Achieve full contact heat exchange and improve drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

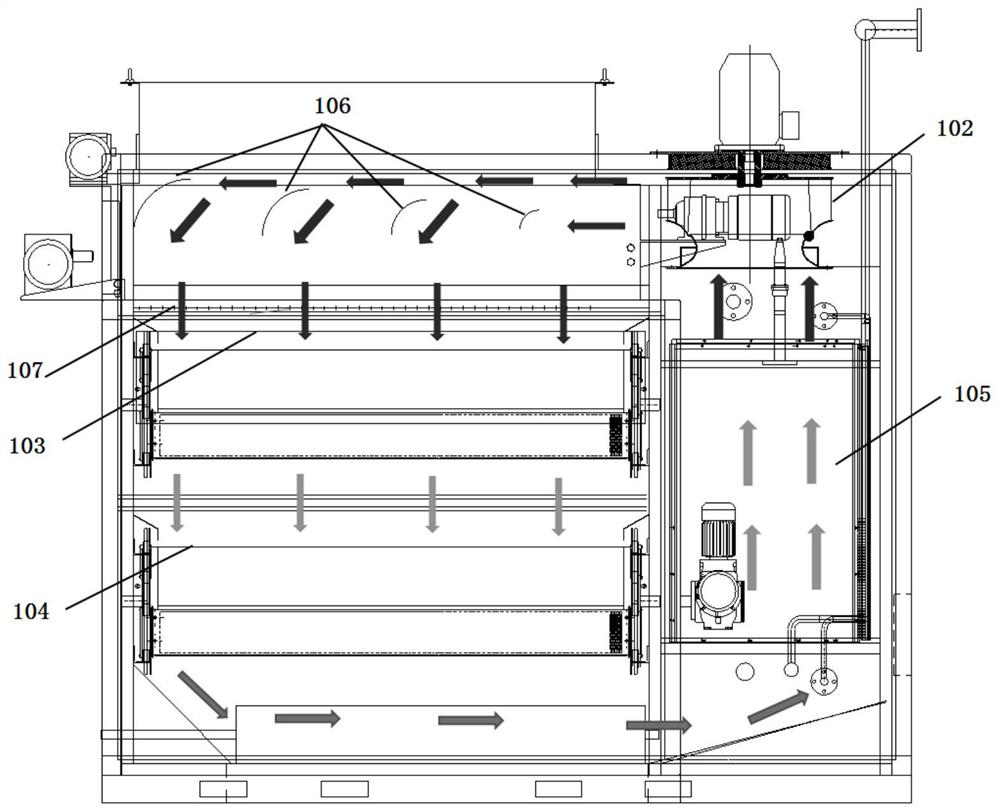

[0041] Briefly describe the principle of a specific air uniform dust removal device provided by the embodiment of the present invention.

Embodiment 2

The air uniform dust removal device described in the first item.

[0048] The embodiment of the present invention can refer to Embodiment 1 in the specific implementation process, and has corresponding technical effects.

[0049] The above-mentioned serial numbers of the embodiments of the present invention are only for description, and do not represent the pros and cons of the embodiments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com