Condensation-type hot-water boiler arranged in triple-pass folding manner

A hot water boiler, folding technology, applied in the directions of air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of environmental pollution, reduced heat exchange effect, large floor space, etc., and achieves a compact overall structure, The effect of reducing floor space and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

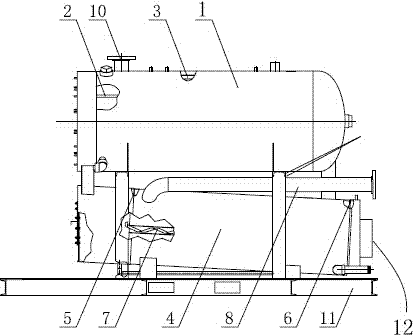

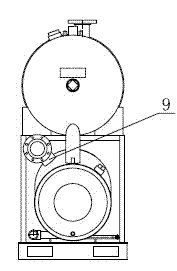

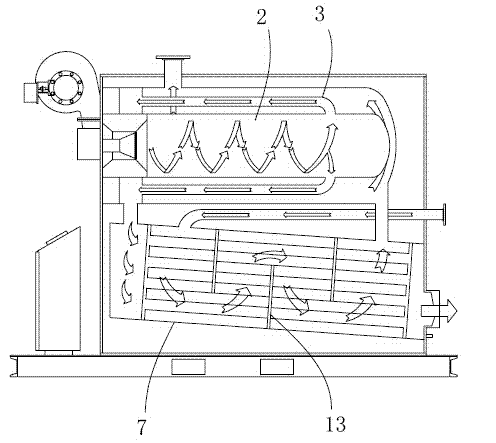

[0023] refer to Figure 1 to Figure 3 As shown, a three-pass folding condensing hot water boiler includes a base 11, a boiler body placed on the base 11, and a burner. The burner is located on the upper part of the boiler body and passes through the smoke in the middle of the front smoke chamber. The indoor wall enters the furnace, and the tail of the boiler body is provided with a smoke outlet 12. The boiler body includes a high-temperature section shell 1, a furnace 2, a high-temperature section smoke pipe 3, and a low-temperature section shell 4, a front tube plate 5, and a rear tube plate 6 , the low-temperature section smoke pipe 7, the low-temperature section shell 4 and the high-temperature section shell 1 are both horizontal and folded, the low-temperature section shell 4 is inclined to the tail, and has a certain inclination with the high-temperature section shell 1 angle.

[0024] The high-temperature section shell 1 covers the furnace 2 and the high-temperature sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com