Waste heat recovery system of quenching tower

A technology of waste heat recovery system and waste heat recovery device, applied in coke oven, coke cooling, cleaning heat transfer device and other directions, can solve the problem of heat waste of saturated steam and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

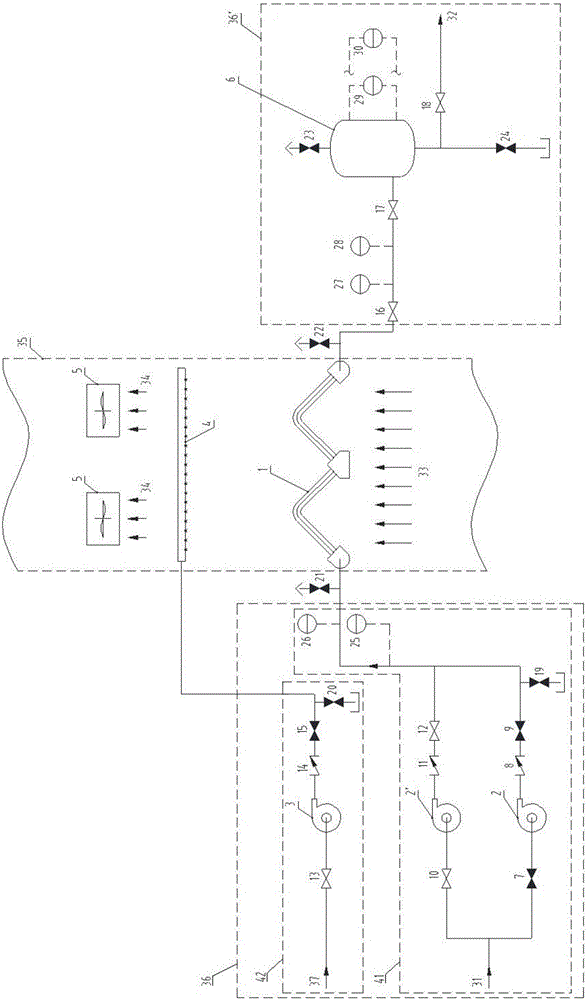

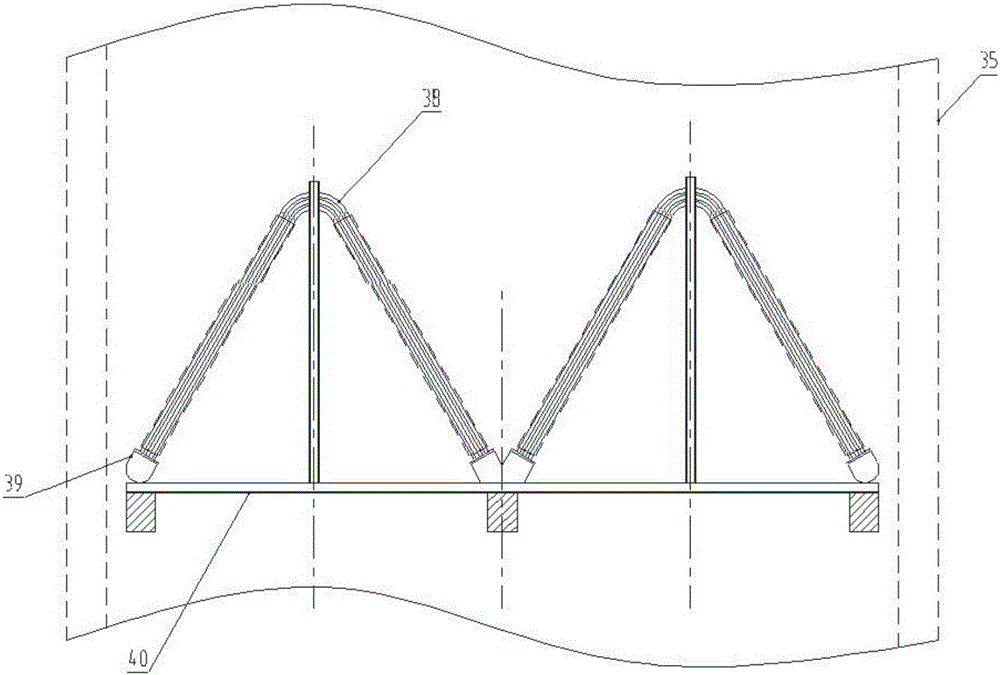

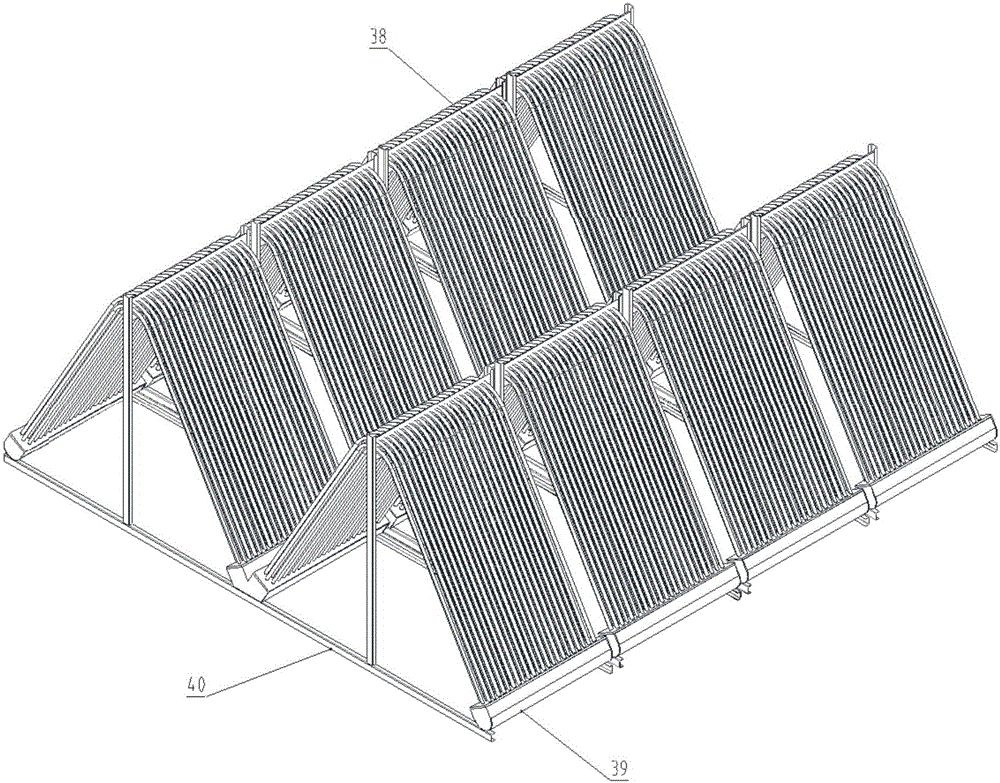

[0030] like Figure 1-2 As shown, a coke quenching tower waste heat recovery system includes a water inlet pipeline 36, a coke quenching tower 35 and an outlet pipeline 36'; wherein the water inlet pipeline 36 includes a water supply pipeline 41 and a cleaning water pipeline 42, and the coke quenching tower 35 It includes a waste heat recovery device 1, a cleaning pipe 4 and an induced draft fan 5; the head end of the water supply pipeline 41 is the water supply inlet 31, and the end is connected to one end of the waste heat recovery device 1; the head end of the cleaning water pipeline 42 is the cleaning water inlet 37, The end is connected with the cleaning pipe 4;

[0031]Specifically, the head end of the water supply pipeline 41 is the water supply inlet 31, and the end is connected to one end of the waste heat recovery device 1. Two parall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com