Capillarity pipe heat exchanger

A capillary tube and heat exchanger technology, which is applied in the field of capillary tube heat exchangers, can solve the problems of low utilization rate of refrigerants and reduced heat exchange efficiency of heat exchangers, and achieve the effects of reducing production costs, uniform pipe spacing, and improving refrigerant utilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the invention are described in detail below, but the invention can be practiced in many different ways as defined and covered by the claims.

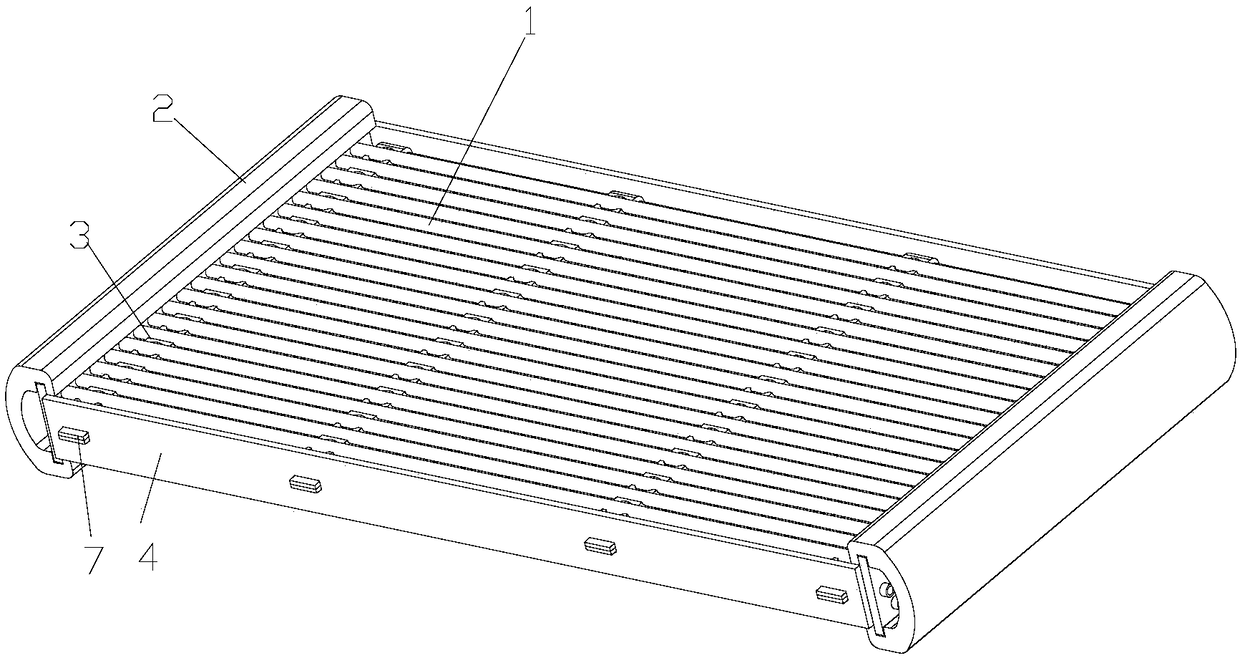

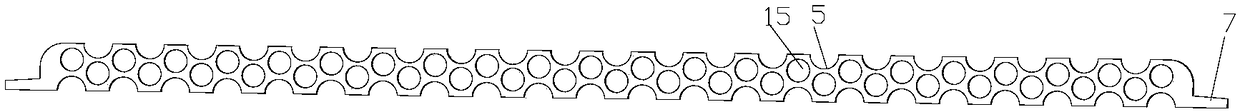

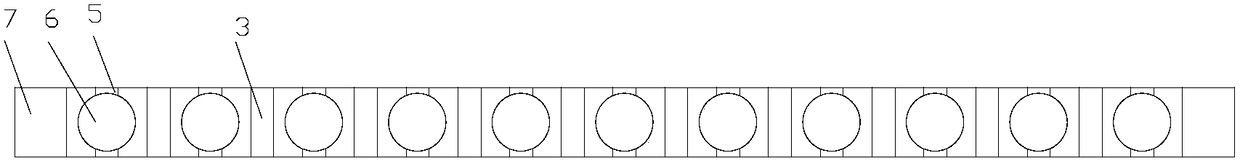

[0023] Please refer to Figure 1 to Figure 3 As shown, according to the first embodiment of the present invention, the capillary heat exchanger includes multiple rows of capillary tubes 1 and headers 2 located at both ends of the capillary tubes 1, each row of capillary tubes 1 includes a plurality of capillary tubes 1 arranged at intervals, and each row of capillary tubes 1 The space is supported and fixed by a support block 3, which extends along the arrangement direction of each row of capillary tubes 1, and the two ends of the support block 3 are fixed by side plates 4 arranged on the header 2.

[0024] Preferably, the top and bottom of the support block 3 are provided with semicircular support grooves 5 matching with the capillary 1, and the semicircular support grooves 5 of two adjacent support blocks 3 are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com