Flue-gas waste-heat recycling system

A flue gas waste heat recovery system technology, which is applied to heat exchanger shells, indirect heat exchangers, heat exchange equipment, etc. Overhaul and maintenance, easy operation and management, easy disassembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

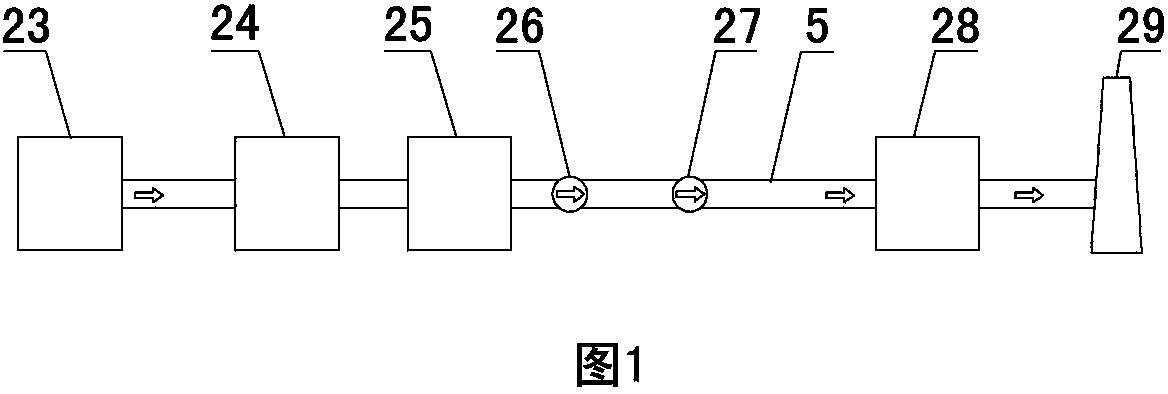

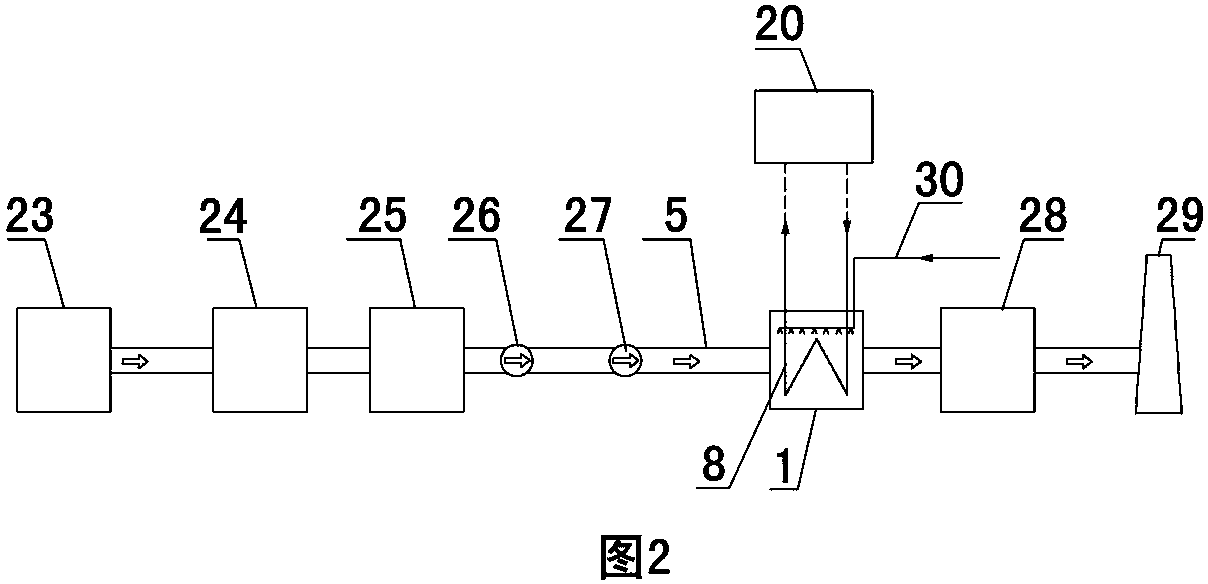

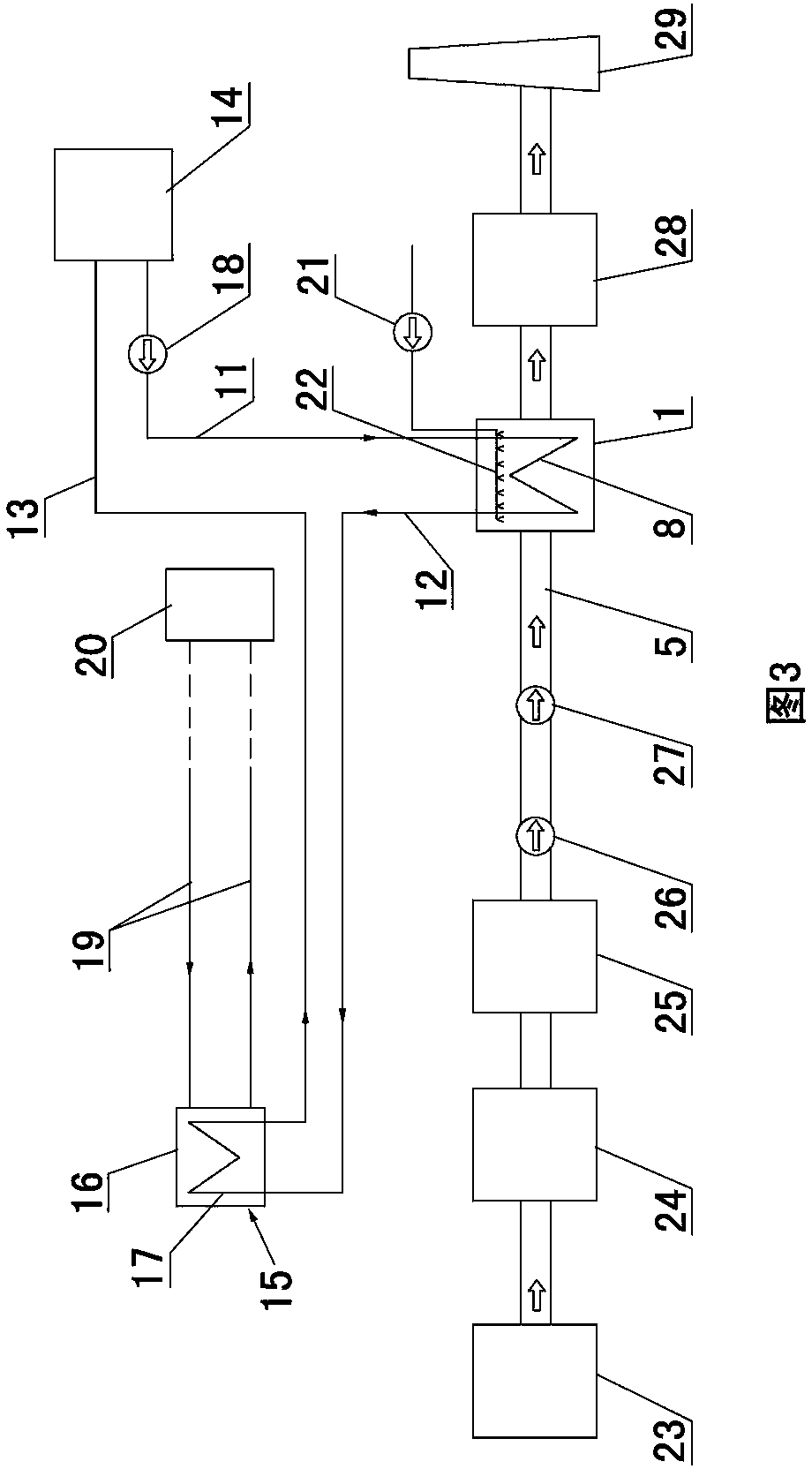

[0040] Examples are shown in Figures 3 and 4. This new type of flue gas waste heat recovery system can be arranged between the outlet of the boiler air preheater and the wet flue gas desulfurization tower (air preheater, dust collector, induced draft fan, booster fan, Wet flue gas desulfurization tower) between any two equipment, or between any two equipment at the same time, the setting position is determined according to the specific needs of users. In this embodiment, it is arranged between the booster fan and the wet flue gas desulfurization tower. When the present invention is arranged at this position, because the wet flue gas desulfurization tower itself has strong anti-corrosion ability, even if the present invention can remove the flue gas The temperature drops below the acid dew point, so the acidic substances in the flue gas after cooling will not cause corrosion hazards to the desulfurization tower. When the present invention is arranged downstream of the outlet of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com