Honeycomb with underground air chamber for ventilation at bottom and die of honeycomb

A technology of underground bees and moulds, which is applied in the field of beekeeping equipment and honeycomb manufacturing, can solve the problems of producing honeycombs without moulds, and achieve the effect of promoting diversification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

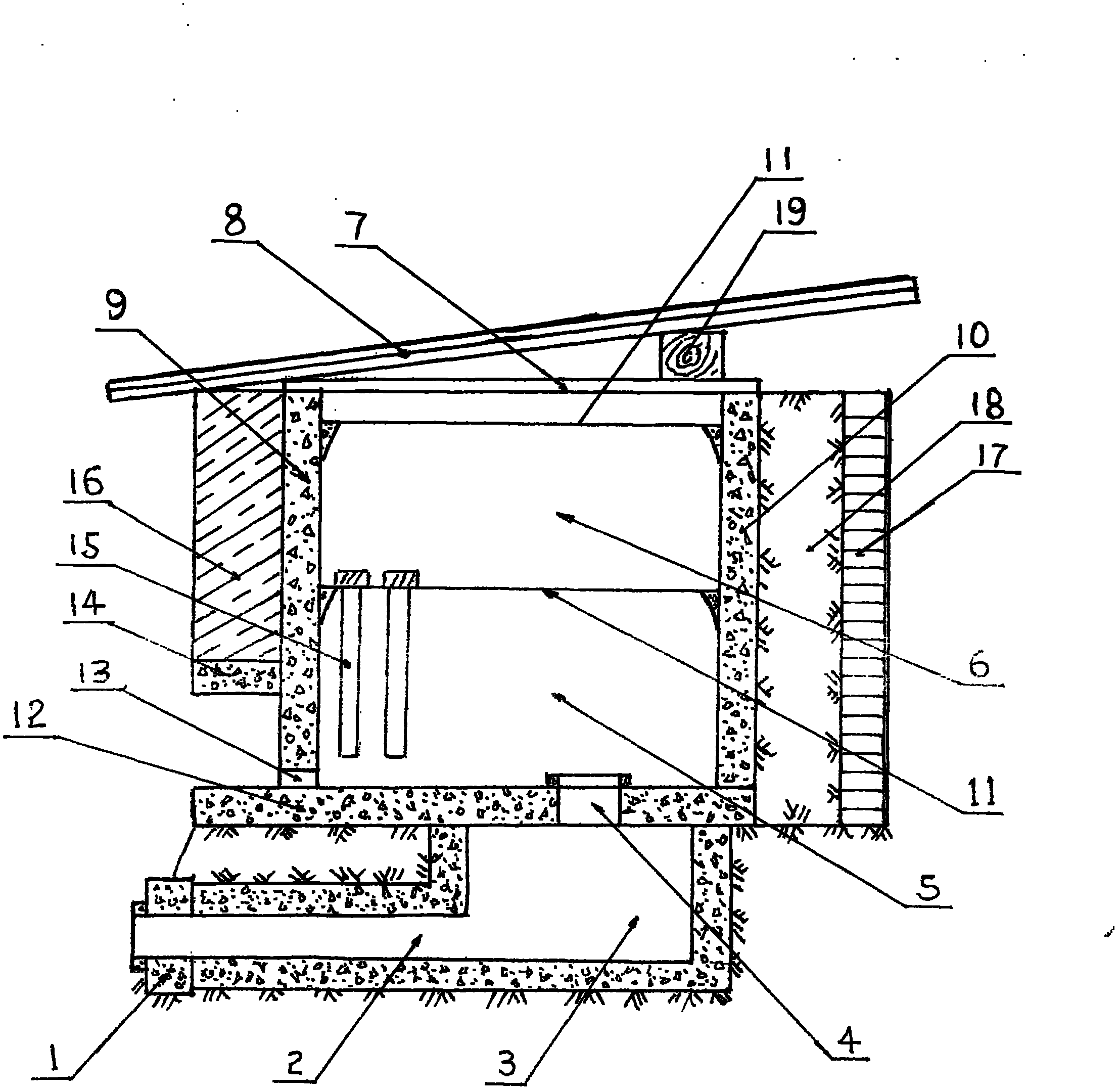

[0010] As shown in the drawings, the system consists of air inlet component 1 from bottom to top; air channel 2; underground air chamber 3; nest bottom window 4; main nest chamber 5; secondary nest chamber 6; gauze cover 7; Composition, like a vertical blast furnace. When the bee colony lives in the main nest chamber 5, it will produce a biological temperature of 35°C, which is higher than the relatively constant temperature of 20-26°C in the ground nest. The hot air rises, passes through the second nest chamber 6, and passes through the gauze cover 7 , discharged from the convex groove of wave tile 8, and new air must be inhaled and replenished from air inlet member 1, enters underground air chamber 3 through air channel 2, enters main nest chamber 5 from nest bottom window 4. In this way, ventilation is carried out again and again, and the speed of the airflow is completely regulated by the bee colony's own needs, such as ball formation or spleen protection. In this way, no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com