Bamboo chopsticks and production process thereof

A production process and technology of bamboo chopsticks, which are applied in the direction of manufacturing tools, wooden sticks, wood processing utensils, etc., can solve the problems of a lot of waste of materials, insufficient utilization of bamboo materials, large processing allowance of ordinary bamboo chopsticks, etc. Easy to clean and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

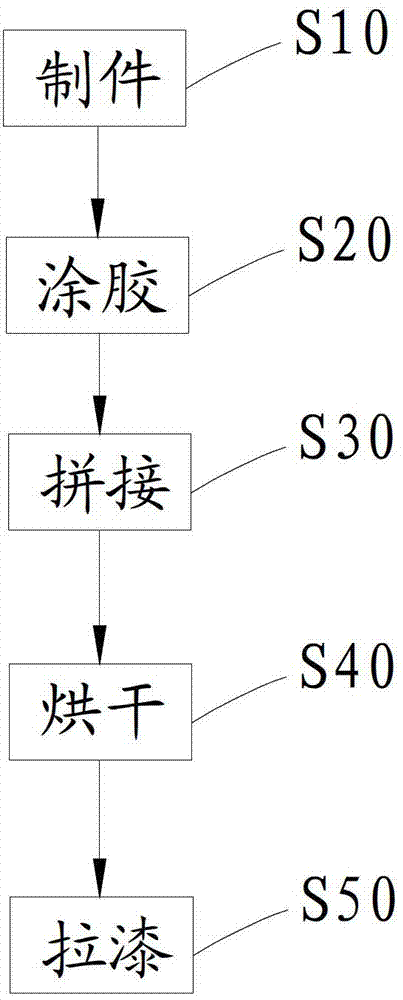

[0029] see figure 1 , the present invention at first provides a kind of manufacture craft of bamboo chopsticks, mainly comprises steps:

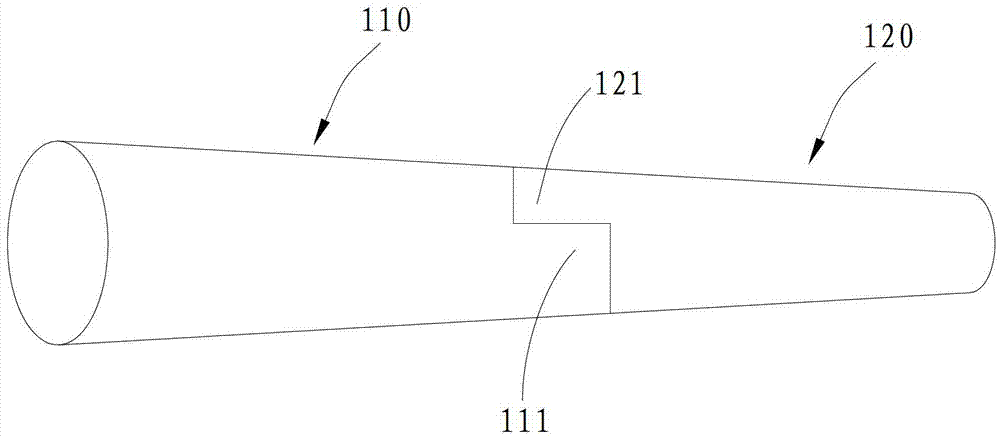

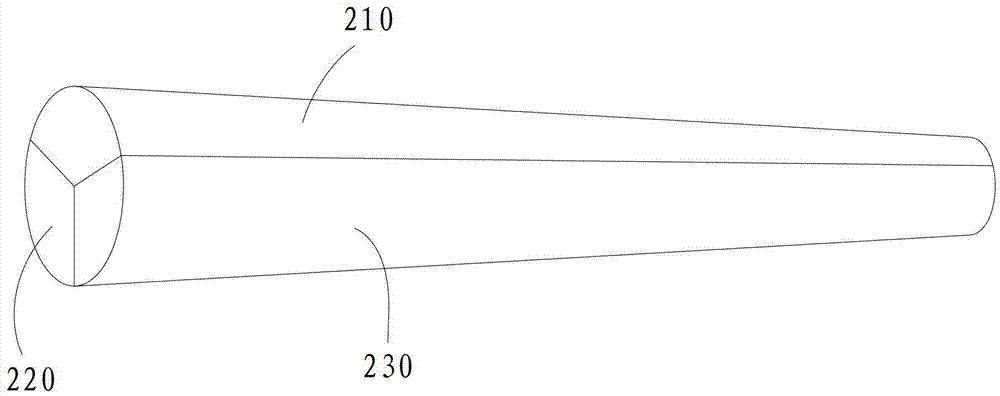

[0030] S10: Manufactured parts; specifically: choose bamboo strips of appropriate thickness to make components of different parts of bamboo chopsticks; wherein, the different parts of bamboo chopsticks formed by each component can be distinguished by the length or thickness of bamboo chopsticks, as long as the components can be It can be spliced into complete bamboo chopsticks. In actual processing, it is necessary to pre-treat the bamboo strips before making the parts to make the bamboo strips meet the use conditions. Specifically, the complete process from raw bamboo to finished components is: raw b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com