Semi-automatic screen printing alignment method

A screen printing, semi-automatic technology, applied in the direction of screen printing machine, printing, printing machine, etc., to achieve the effect of precise alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

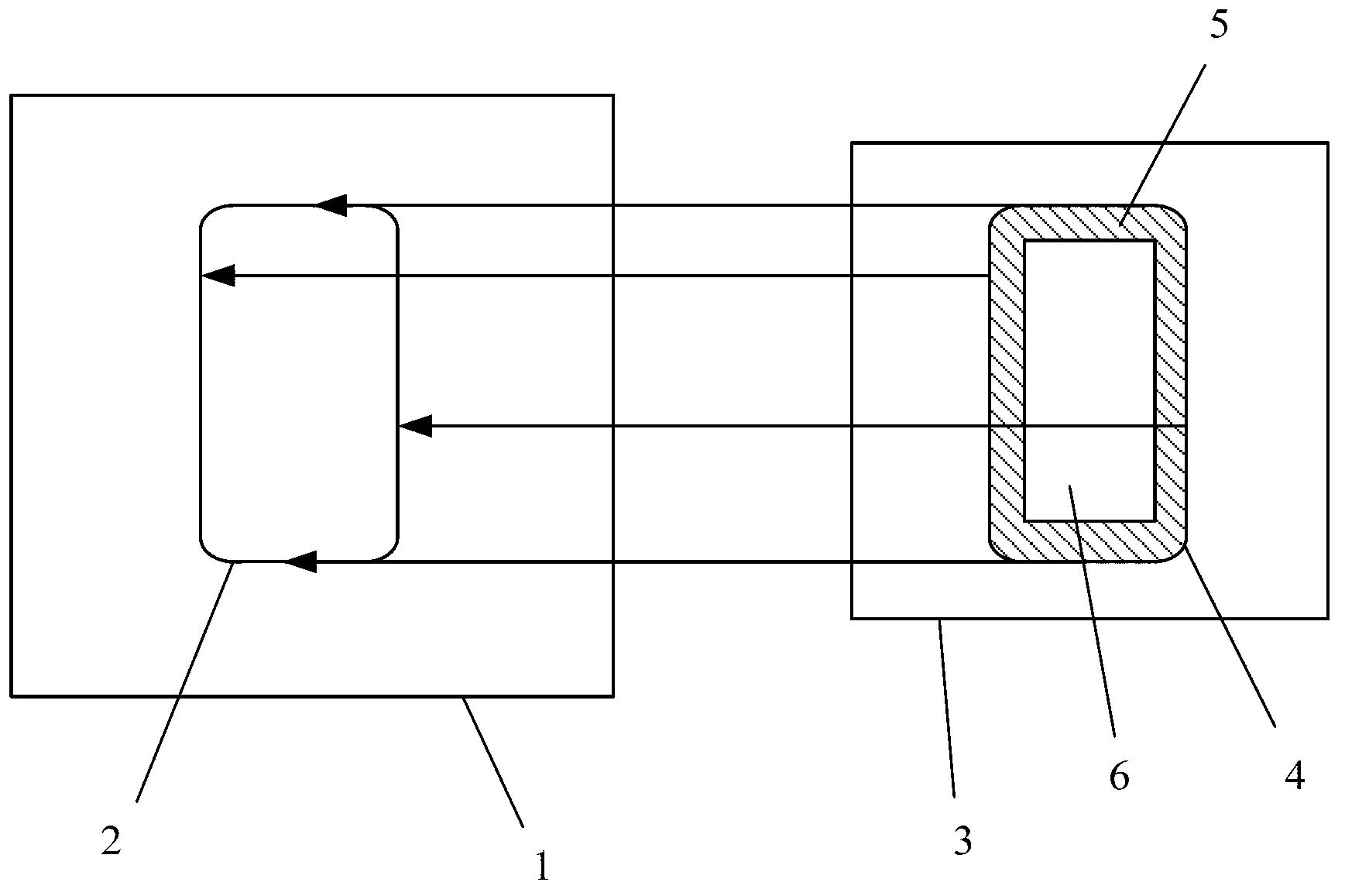

[0028] refer to figure 1 , figure 1 It is a schematic diagram of the principle of the existing semi-automatic screen printing alignment method. When performing alignment, the screen printing jig 1 is fixed on the printing platen, the substrate to be printed is placed on the film loading position 2 of the screen printing jig 1, the screen 3 is placed above the screen printing jig, and then the screen 3 is placed on the The boundary line of the mesh pattern 4 can be aligned with the boundary of the substrate to be printed, as shown by the arrow in the figure.

[0029] It should be noted, figure 1 The mesh pattern 4 mentioned in the above is only a figure suitable for traditional semi-automatic screen printing, not the shape of the substrate to be printed.

[0030] Wherein, the mesh pattern 4 includes: an effective printing area 5 and an ineffective printing area 6 . The effective printing area 5 is a permeable area for paste, and the lower part can be observed through the ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com