Inkjet recording medium and ink set, and inkjet recording method

一种喷墨记录介质、记录介质的技术,应用在复制/标记方法、油墨、涂层等方向,能够解决没有如低定影性能和起皱、高图像密度、难以获得等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

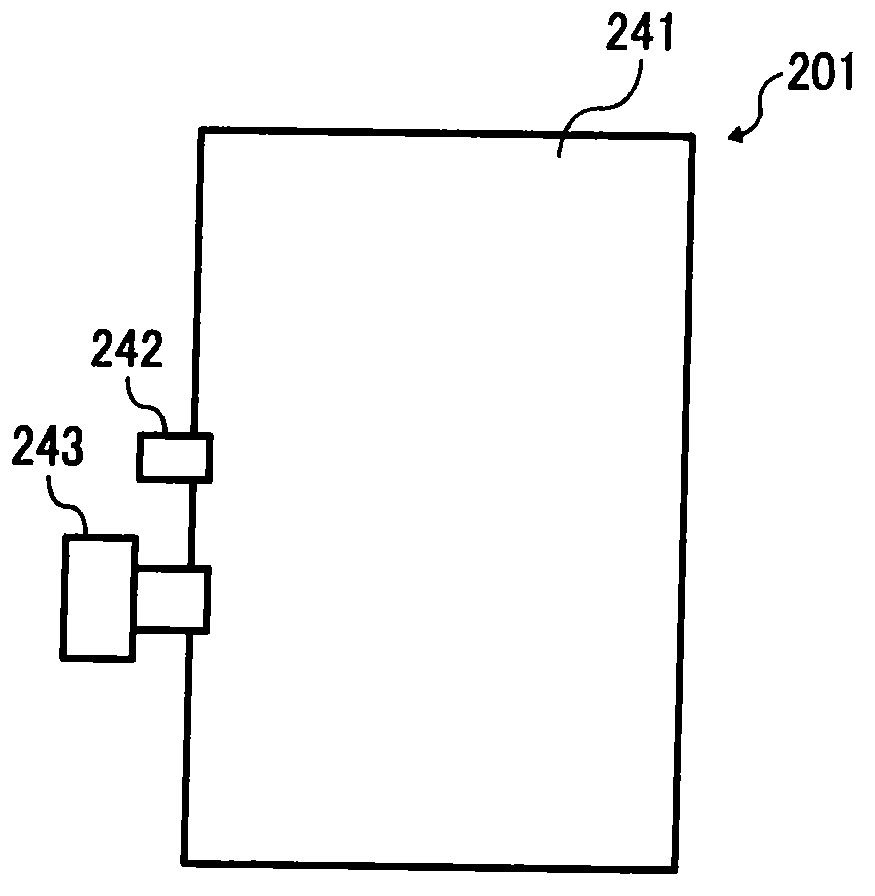

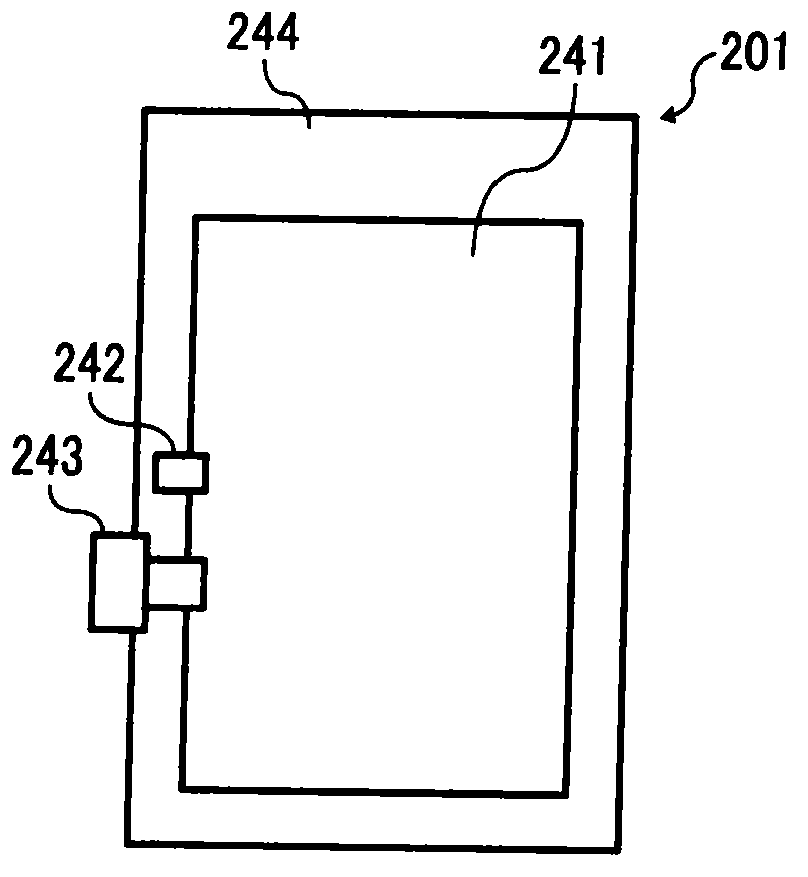

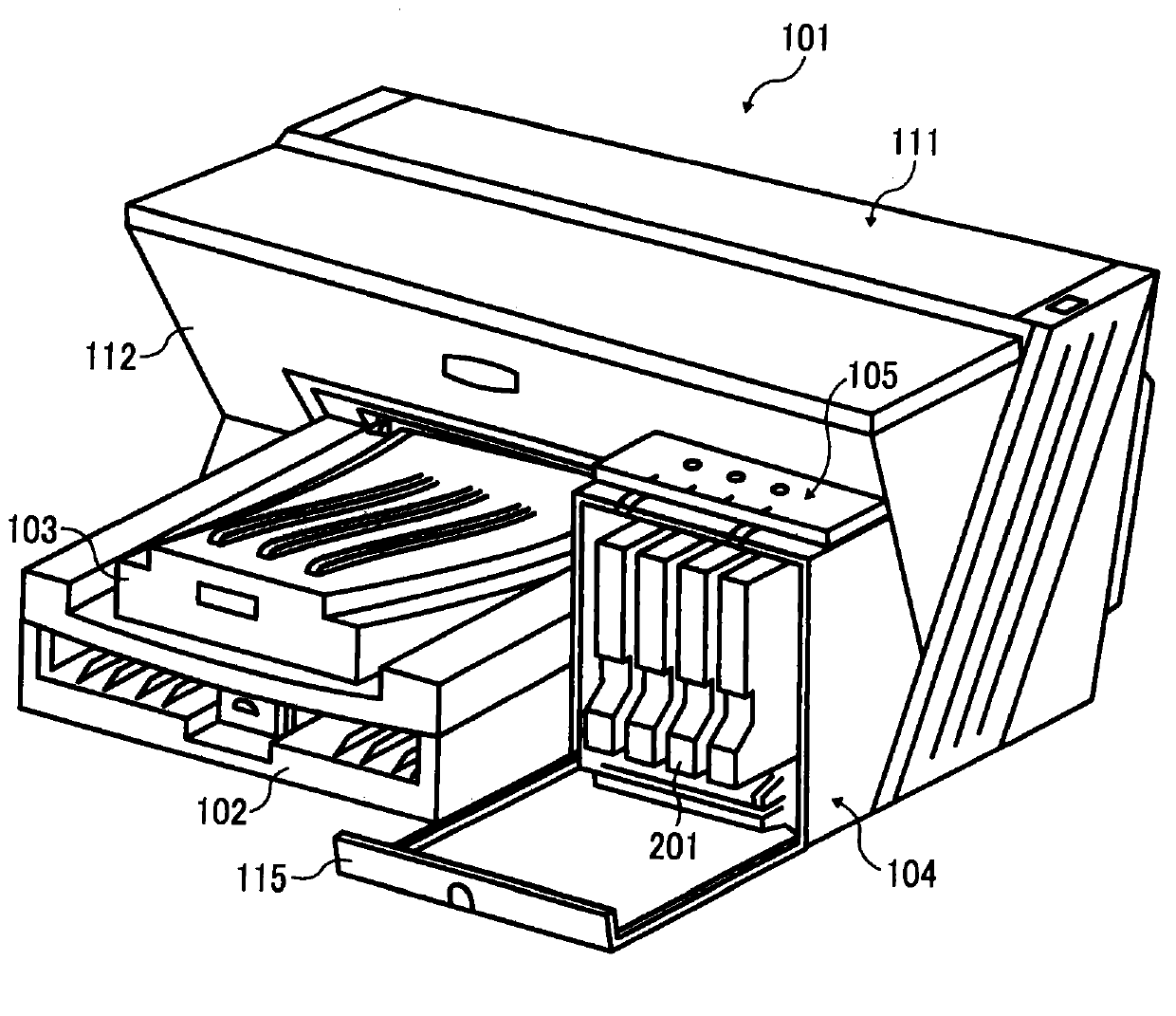

Image

Examples

preparation Embodiment 1

[0422] Preparation of Aqueous Solution A of Waterborne Polymer

[0423] α-olefin-maleic anhydride (T-YP112, olefin chain (R) represented by chemical structure 2 having an acid value of 190 mgKOH / g and a weight-average molecular weight of 10,000: number of carbon atoms: 20 to 24, corresponding to An alkyl group having 18 to 22 carbon atoms in R of II, manufactured by SEIKO PMC CORPORATION): 10 parts

[0424] 1 normality LiOH aqueous solution (having an acid value 1.2 times that of the α-olefin-maleic anhydride copolymer represented by chemical structure 1): 17.34 parts

[0425] · Deionized water: 72.66 parts

[0426] The mixture of the above-indicated formulation was heated and stirred to dissolve α-olefin-maleic anhydride represented by chemical structure 2, followed by filtering trace insoluble matter with a filter having an average opening of 5 μm to prepare an aqueous polymer solution A.

preparation Embodiment 2

[0428] Preparation of liquid dispersions of surface-treated black pigments

[0429] Will 90g have 150m 2 Carbon black having a specific surface area of CTAB / g and a DBP oil absorption of 100ml / 100g was added to 3,000ml of a 2.5N sodium sulfate solution, and an oxidation treatment reaction was performed by stirring at 300rpm at 60°C for 10 hours.

[0430] The reaction solution was filtered and the filtered carbon black was neutralized by sodium hydroxide, followed by ultrafiltration.

[0431] The carbon black thus obtained was washed with water. Carbon black was dried and dispersed in pure water so that the solid portion of carbon black was 30% by weight, followed by sufficient stirring to obtain a liquid dispersion of a black pigment.

[0432] The average particle diameter (D50) of the pigment dispersion in this black pigment liquid dispersion was 103 nm. The average particle diameter (D50) is measured by a particle size distribution measuring instrument (Nanotrac UPA-EX-...

preparation Embodiment 3

[0434] Preparation of liquid dispersions of polymer particles comprising magenta pigments

[0435] Preparation of polymer solution A

[0436] After being fully replaced with nitrogen in a flask equipped with a mechanical stirrer, a thermometer, a nitrogen introduction tube, a reflux tube, and a dropping funnel, 11.2 g of styrene, 2.8 g of acrylic acid, and 12.0 g of lauryl methacrylate were mixed in the flask. ester, 4.0 g of polyethylene glycol methacrylate, 4.0 g of styrene macromer and 0.4 g of mercaptoethanol and heated the system to 65 ° C, and dropped 100.8 g of styrene in the flask within 2.5 hours , 25.2g of acrylic acid, 108.0g of lauryl methacrylate, 36.0g of polyethylene glycol methacrylate, 60.0g of hydroxyethyl methacrylate, 36.0g of styrene macromonomer, 3.6g of A mixture of mercaptoethanol, 2.4 g of azobisdimethylvaleronitrile, and 18 g of methyl ethyl ketone.

[0437] Subsequently, a liquid mixture of 0.8 g of azobisdimethylvaleronitrile and 18 g of methyl et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com