Motorcycle cushion lock mechanism

A seat cushion lock, motorcycle technology, applied to bicycle locks, building locks, locks, etc., can solve the problems of misalignment of the lock cylinder, difficulty in controlling the accuracy of the installation position, and difficult assembly, so as to achieve smooth and fast assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

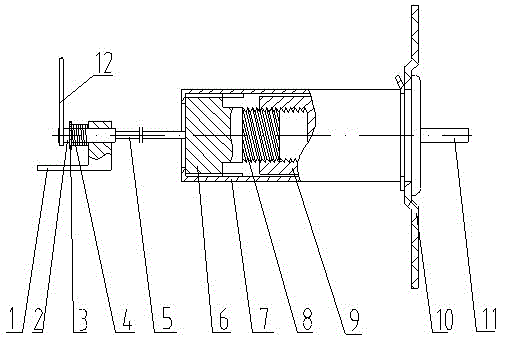

[0015] In specific implementation, such as figure 1 As shown, a motorcycle seat cushion lock mechanism includes a lock body part structure and a locking part structure that are arranged oppositely, the lock body part structure is fixed on the cover 10, and the locking part structure is fixed on the vehicle frame , wherein a straightened flexible pull cord 5 is arranged between the lock body part structure and the locking part structure, and when the lock core of the lock body part structure is turned by the key 11, the lock bar of the lock part structure can be pulled by the flexible stay cord 5 2.

[0016] Wherein, the partial structure of the lock body includes a cylindrical lock case 7 fixed on the cover, the outer end of the lock case 7 passes through the cover 10 and the lock cylinder 9 is arranged inside the outer end, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com