Railway vehicle ceiling plate mounting structure

A rail vehicle and installation structure technology, applied to the direction of the railway roof, etc., can solve the problems of simple installation, unsightly, low quality, etc., and achieve the effect of simple assembly, easy maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

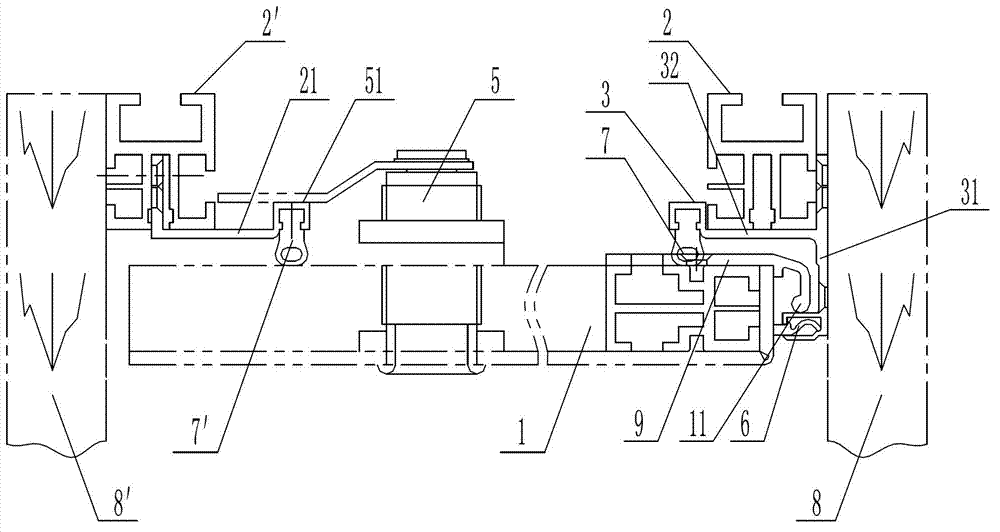

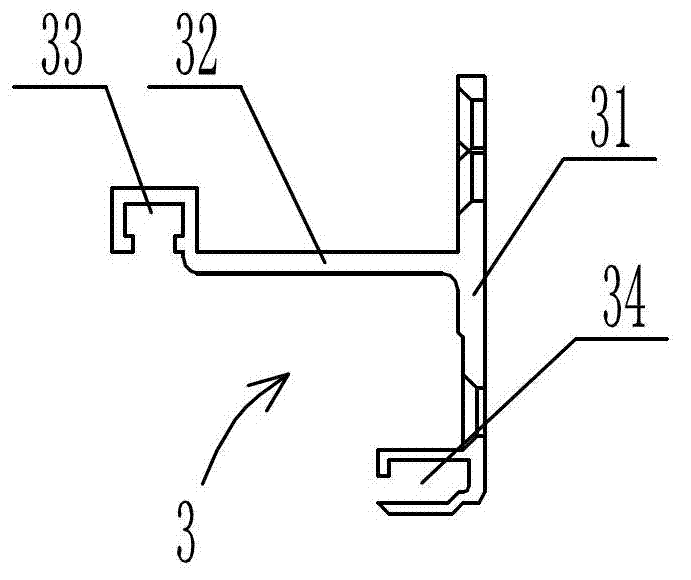

[0011] Such as figure 1 As shown, the installation structure of the flat roof plate of the rail vehicle in this embodiment consists of: the first partition wall 8 and the second partition wall 8' of the vehicle opposite to each other in parallel, the first flat roof frame 2, the second flat roof frame 2', and the The improvement of the flat roof 1 between a flat roof frame 2 and the second flat roof frame 2' is that it also includes a T-shaped first connecting piece 3 with a vertical plate 31 and a flat plate 32, and the first connecting piece 3 The vertical plate 31 is fixedly connected with the first partition wall 8 of the vehicle. The first flat roof frame 2 is placed on the flat plate 32 of the first connecting member 3 and fixedly connected by screws. The lower end of the vertical plate 31 of the first connecting member 3 has an opening facing the inside of the vehicle. The first groove 34, the first groove 34 is embedded with an adjustable rubber block 6, the first end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com