Method for recovering valuable metals

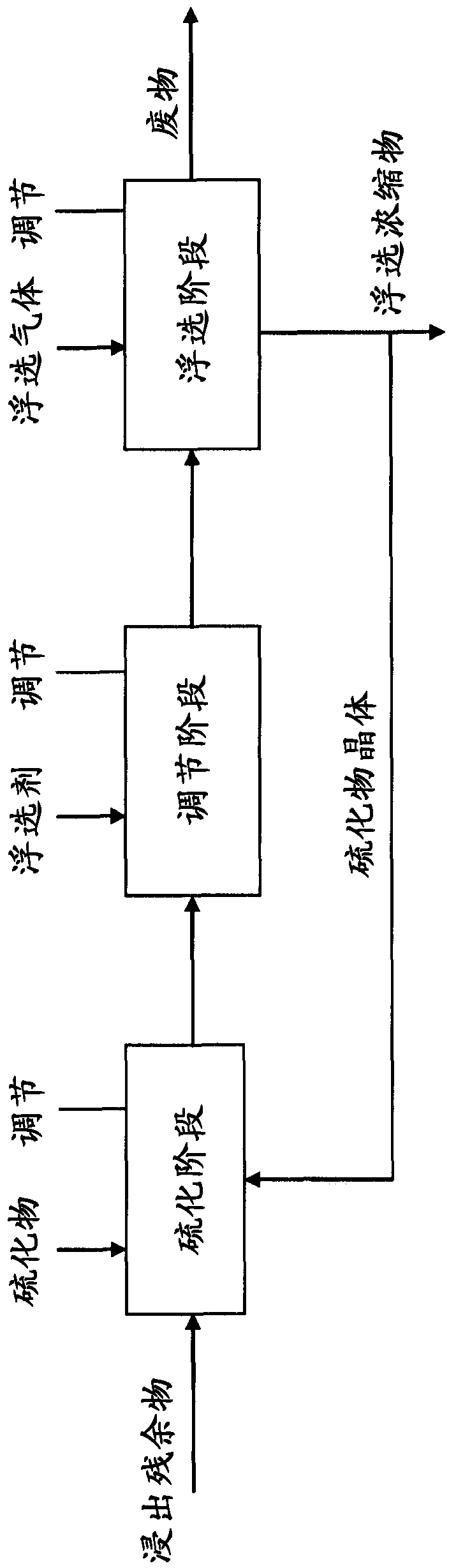

A metal and process technology, which is applied in the field of recycling valuable metals, can solve the problems of inability to flotation, difficulties in metal sulfate flotation, weakening of sulfide flotation performance, etc., and achieve the effect of increased yield and easy oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] After strong acid leaching, the sulfidation and flotation of the residue were studied using laboratory tests. In terms of major components, the supplied material has the following composition: Pb 19.3%, Ag 720g / t, Au 2.3g / t. In addition, the material is mainly composed of zinc and iron compounds, gypsum and silicate minerals.

[0031] After strong acid leaching, the residue was sulfided in a closed reactor by using a stoichiometric amount of sulfide relative to lead at a pH of 1.5–3 at a temperature of 50 °C during a period of 3 hours. The sulfide was fed to the slurry as a 2.5M solution.

[0032] After sulfidation, the slurry is subjected to flotation to concentrate lead, silver and lead. The flotation process consists of a coarse flotation stage and four cleaner flotation stages. In Experiment 1, no electrochemical conditioning was applied in the flotation, but it was usually carried out with air as the flotation gas. In the experiments, the pH of the slurry was a...

Embodiment 2

[0034] In Experiment 2, flotation was additionally carried out in the same manner as in Example 1, but in the flotation stage the potential was adjusted to values up to +200 mV vs. SHE using the composition of the flotation gas and adding NaHS solution.

[0035] The yield of lead in the fourth cleaner concentrate is now 87.9%, and the concentration in the concentrate is 56.2%. For silver, the corresponding readings were: 90.6% yield and 2160g / t. The gold yield was 77.5% and its content in the concentrate was 5.8g / t.

[0036] This example shows that by adjusting the slurry potential in the flotation stage to an appropriate range, detrimental oxidation of sulfide minerals can be prevented, while, however, maintaining such electrochemical conditions favors flotation. Depending on the collector chemistry and its content, the redox potential for a pH range of 2 to 4 is typically -50 to +350 mV versus SHE.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com