Circular water-cooling crystallizer ingot mould

A crystallizer and ingot mold technology, which is applied in the field of circular water-cooled crystallizer ingot molds, can solve the problems that the ingot mold cannot be fully utilized, the size of the steel ingot mold cannot be adjusted, and the production cost is increased.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

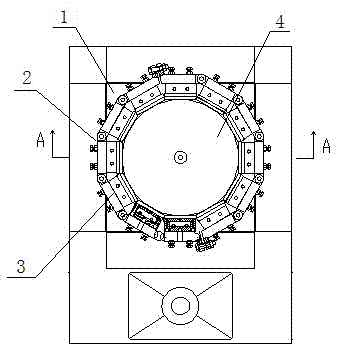

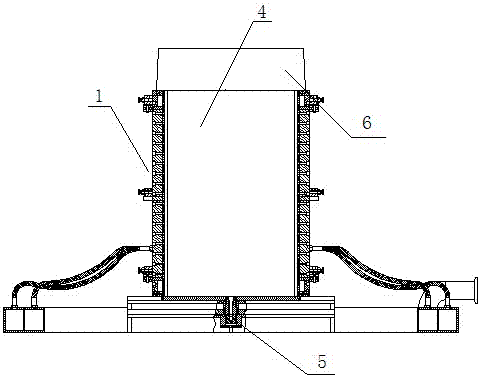

[0020] Such as figure 1 , figure 2 , Figure 4 Shown: a circular water-cooled crystallizer ingot mold, including an ingot mold bottom plate 1 and a crystallizer body 2 arranged on the ingot mold bottom plate 1, a pouring channel 5 communicating with a mold cavity 4 is arranged in the ingot mold bottom plate 1, The upper part of the crystallizer body 1 is provided with a thermal insulation cap 6, and the crystallizer body includes a plurality of cooling copper plate units 3 that are movably connected. The two opposite pieces 12A can be replaced by 12B. The angle at the junction does not change. The regular decagon becomes an irregular decagon with a larger perimeter.

Embodiment 2

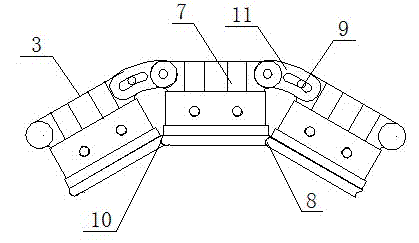

[0022] Such as figure 1 , figure 2 , image 3 , Figure 5 Shown: a circular water-cooled crystallizer ingot mold, including an ingot mold bottom plate 1 and a crystallizer body 2 arranged on the ingot mold bottom plate 1, a pouring channel 5 communicating with a mold cavity 4 is arranged in the ingot mold bottom plate 1, The upper part of the crystallizer body 1 is provided with a thermal insulation cap 6, and the crystallizer body includes a plurality of cooling copper plate units 3 that are movably connected. The cooling copper plate unit 3 includes a cooling copper plate unit body 7 and a connection mechanism, the connection mechanism includes a sub-connection mechanism arranged on one side of the cooling copper plate unit body 7 and a female connection mechanism on the other side, the sub-connection mechanism It includes a raised supporting surface 8 on the inner side of the cooling copper plate unit body 7 and a clamp auxiliary locking slide bar 9 on the outer side. T...

Embodiment 3

[0024] Such as figure 1 , figure 2 , image 3 , Figure 5 Shown: a circular water-cooled crystallizer ingot mold, including an ingot mold bottom plate 1 and a crystallizer body 2 arranged on the ingot mold bottom plate 1, a pouring channel 5 communicating with a mold cavity 4 is arranged in the ingot mold bottom plate 1, The upper part of the crystallizer body 1 is provided with a thermal insulation cap 6, and the crystallizer body includes a plurality of cooling copper plate units 3 that are movably connected. The cooling copper plate unit 3 includes a cooling copper plate unit body 7 and a connection mechanism, the connection mechanism includes a sub-connection mechanism arranged on one side of the cooling copper plate unit body 7 and a female connection mechanism on the other side, the sub-connection mechanism It includes a raised supporting surface 8 on the inner side of the cooling copper plate unit body 7 and a clamp auxiliary locking slide bar 9 on the outer side. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com