Circular water-cooling crystallizer ingot mould

A crystallizer and ingot mold technology, which is applied in the field of circular water-cooled mold ingot molds, can solve the problems of increasing the investment of steel ingot molds, increasing production costs, and incapable of making full use of ingot molds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

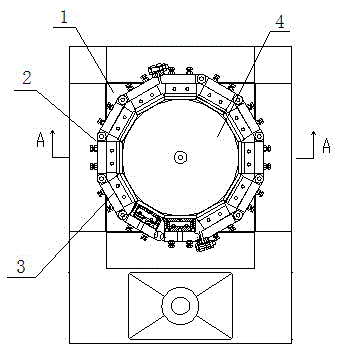

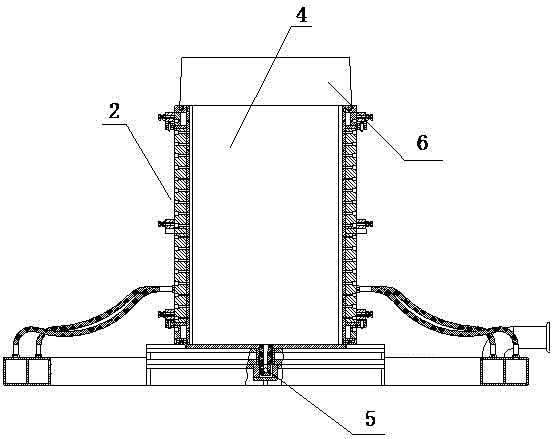

[0020] Such as figure 1 , figure 2 , Figure 4 Shown: a circular water-cooled crystallizer ingot mold, including an ingot mold bottom plate 1 and a crystallizer body 2 arranged on the ingot mold bottom plate 1, a pouring channel 5 communicating with a mold cavity 4 is arranged in the ingot mold bottom plate 1, The upper part of the crystallizer body 1 is provided with a thermal insulation cap 6, and the crystallizer body includes a plurality of cooling copper plate units 3 that are movably connected. The two opposite pieces 12A can be replaced by 12B. The angle at the junction does not change. The regular decagon becomes an irregular decagon with a larger perimeter.

Embodiment 2

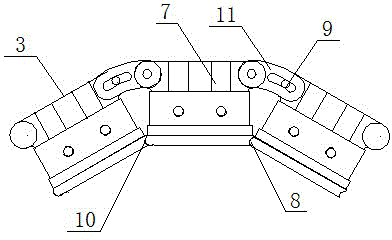

[0022] Such as figure 1 , figure 2 , image 3 , Figure 5 Shown: a circular water-cooled crystallizer ingot mold, including an ingot mold bottom plate 1 and a crystallizer body 2 arranged on the ingot mold bottom plate 1, a pouring channel 5 communicating with a mold cavity 4 is arranged in the ingot mold bottom plate 1, The upper part of the crystallizer body 1 is provided with a thermal insulation cap 6, and the crystallizer body includes a plurality of cooling copper plate units 3 that are movably connected. The cooling copper plate unit 3 includes a cooling copper plate unit body 7 and a connection mechanism, the connection mechanism includes a sub-connection mechanism arranged on one side of the cooling copper plate unit body 7 and a female connection mechanism on the other side, the sub-connection mechanism It includes a raised supporting surface 8 on the inner side of the cooling copper plate unit body 7 and a clamp auxiliary locking slide bar 9 on the outer side. T...

Embodiment 3

[0024] Such as figure 1 , figure 2 , image 3 , Figure 5 Shown: a circular water-cooled crystallizer ingot mold, including an ingot mold bottom plate 1 and a crystallizer body 2 arranged on the ingot mold bottom plate 1, a pouring channel 5 communicating with a mold cavity 4 is arranged in the ingot mold bottom plate 1, The upper part of the crystallizer body 1 is provided with a thermal insulation cap 6, and the crystallizer body includes a plurality of cooling copper plate units 3 that are movably connected. The cooling copper plate unit 3 includes a cooling copper plate unit body 7 and a connection mechanism, the connection mechanism includes a sub-connection mechanism arranged on one side of the cooling copper plate unit body 7 and a female connection mechanism on the other side, the sub-connection mechanism It includes a raised supporting surface 8 on the inner side of the cooling copper plate unit body 7 and a clamp auxiliary locking slide bar 9 on the outer side. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com