Welding and assembling base for high-power energy-saving lamp

A technology for welding assembly and energy-saving lamps, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inability to achieve high power and low brightness, and achieve simple structure, economical and practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

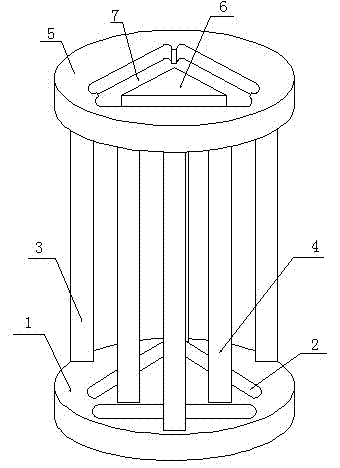

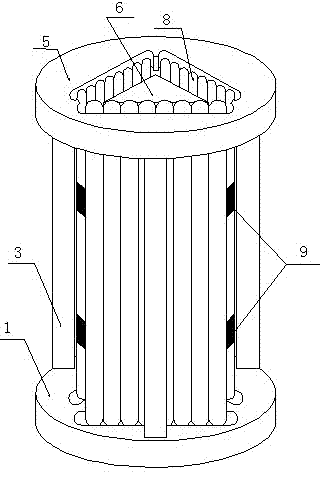

[0014] The present invention as figure 1 , 2 shown.

[0015] The welding and assembly base of high-power energy-saving lamps includes a base 1, which is provided with a sinking groove 2 matching with the tail end of the 9U lamp tube 8, and the sinking groove 2 is distributed in an equilateral triangle; the sinking groove 2 is provided with a plurality of pillars 3. The inner space of the sinking tank 2 is provided with a pillar 2 4, the top of the pillar 3 is provided with a support 5 corresponding to the base 1, the top of the pillar 2 4 is provided with an equilateral triangle positioning seat 6, the support 5 and the equilateral A positioning cavity 7 is formed between the triangular positioning seats 6 .

[0016] The support 5 and the base 1 are two circles with equal diameters.

[0017] There are three pillars one 3 and they are evenly distributed outside the sinker 2 on the base 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com