Method for calculating front frame strength of wind generating set

A technology for wind turbines and calculation methods, which is applied in the fields of calculation, electrical digital data processing, special data processing applications, etc., can solve the influence of bearing stiffness without consideration, the force deviation of the front frame under force state, and only consider the impact of the bearing stiffness. influence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

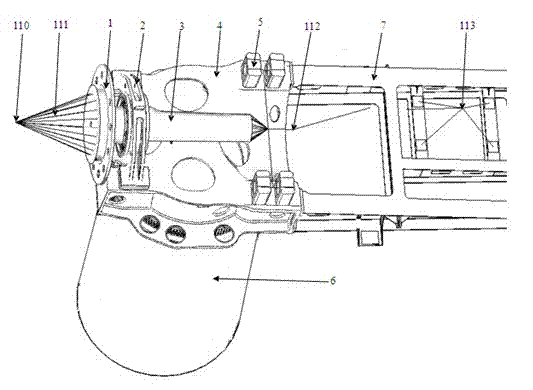

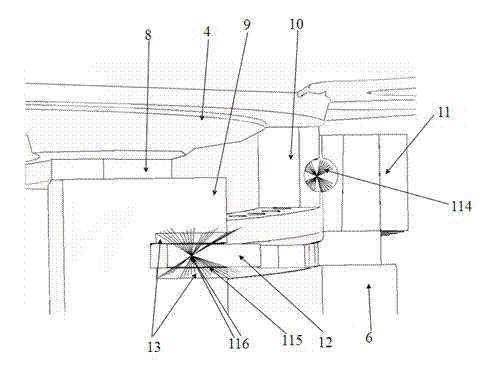

[0020] Attached below figure 1 with 2 The present invention will be further described.

[0021] In the process of establishing the geometric model, it is necessary to simplify the features that have little influence on the strength, such as small chamfers, bosses, etc. The specific implementation steps of the present invention are as follows:

[0022] First, use 3D software to establish the geometric model of the front frame 4 and the geometric model of the parts that affect the force of the front frame, including the wind wheel locking disc 1, the main bearing seat 2, the main shaft 3, the front frame 4, and the gearbox support 5. Tower tube 6, rear frame 7, yaw pad 8, yaw brake 9, yaw bearing inner ring 10, yaw bearing outer ring 11, yaw brake disc 12, upper yaw friction plate and The lower yaw friction plate 13 is assembled and converted into a format recognized by the grid software, and imported into the grid software to divide all parts into grids to form a grid model f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com