Process and apparatus for melt-spinning, drawing and winding multiple synthetic threads

A technology of melt spinning and filament, which is applied in the field of melt spinning, stretching and winding multiple synthetic filaments to achieve the effect of uniform productivity and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

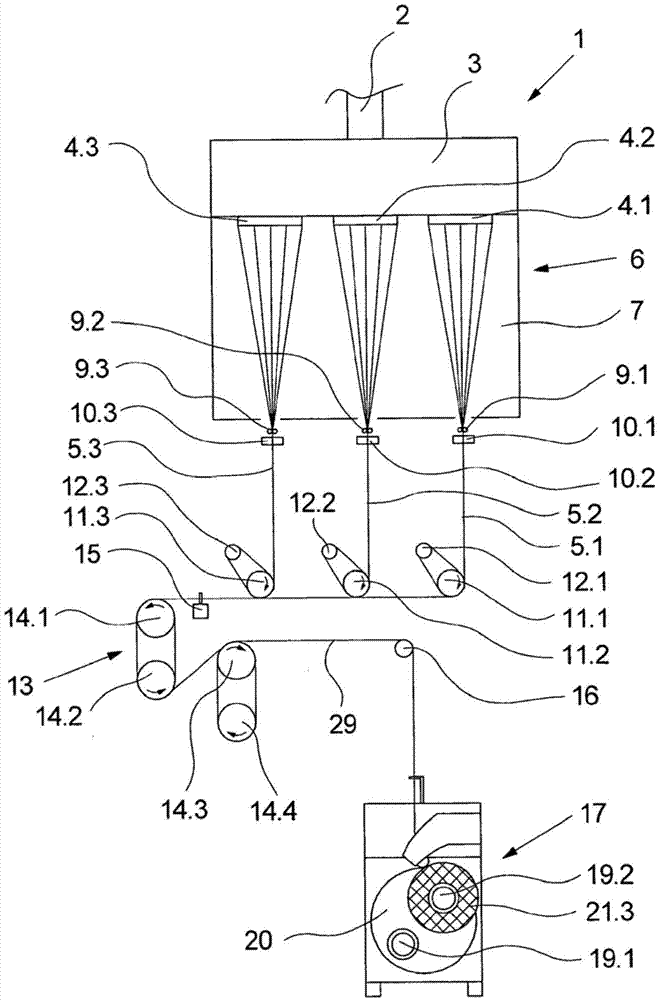

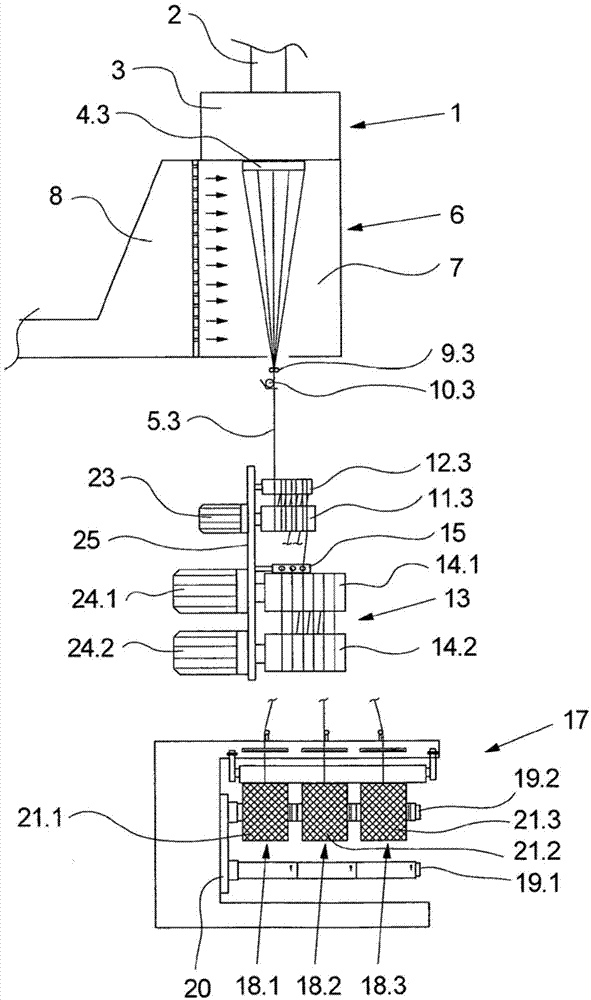

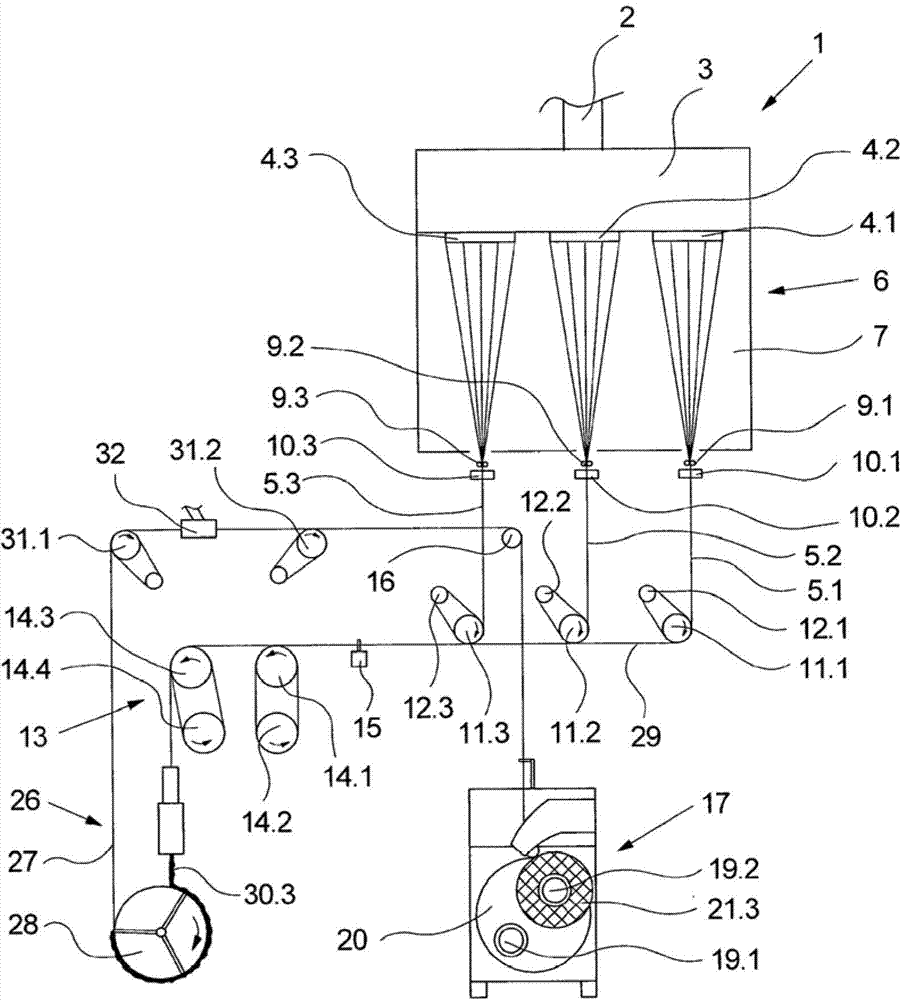

[0027] exist figure 1 and figure 2 A first exemplary embodiment of the device according to the invention for carrying out the method according to the invention is shown schematically in several views. figure 1 The embodiment is shown in front view, figure 2 Shown in side view. The following description applies to both figures unless otherwise specified for the figures.

[0028] according to figure 1 and 2 The exemplary embodiment of the invention has a spinning device 1 with a total of three spinning nozzles 4.1, 4.2 and 4.3 arranged side by side. The number of spinning nozzles in the spinning device 1 is exemplary, but also much more than three filaments per spinning position. The spinning nozzles 4.1 , 4.2 and 4.3 are held on the bottom of the heated spin beam 3 . The spin beam 3 also includes melt-conducting elements, not shown here, in order to feed the melt-sourced thermoplastic melt supplied via the inlet 2 to the spinning nozzles 4.1 to 4.3. At least one or mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com